The role of high performance clutches in sports car maintenance

Beyond the Basics of Standard Cl: Enhanced Functionality

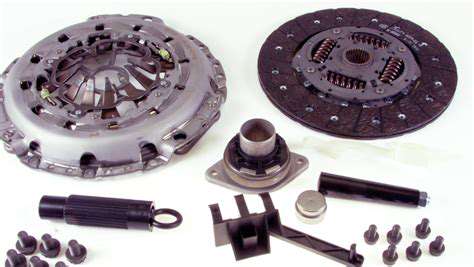

Standard clutches, while reliable for everyday driving, often struggle under the intense demands of sports car performance. The root cause lies in their design, which prioritizes durability over the rapid engagement and heat resistance needed for high-speed driving. Upgrading to a performance clutch isn't just an option—it's a necessity for drivers who push their vehicles to the limit. This deep dive explores why standard components fall short and how specialized solutions deliver superior results on the track.

Recognizing a standard clutch's limitations helps drivers make informed upgrade decisions. The difference becomes stark when comparing stop-and-go commuting with aggressive downshifting before tight corners. Sports car enthusiasts quickly learn that stock components simply can't handle repeated high-RPM launches without premature wear or failure.

Key Considerations for Performance Clutch Upgrades

Transitioning to a high-performance clutch introduces new considerations. The increased clamping force that prevents slippage during hard acceleration also demands more leg effort from the driver. While some view this as authentic sports car feedback, others may find it fatiguing during daily use. Proper break-in procedures become absolutely critical—a rushed 500-mile bedding period can mean the difference between a clutch that lasts seasons versus one that fails prematurely.

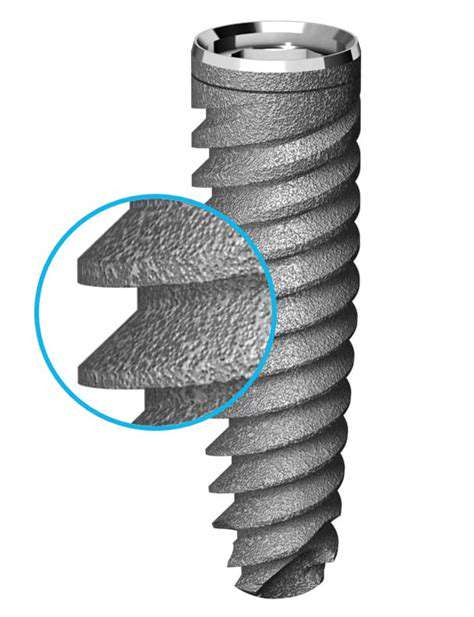

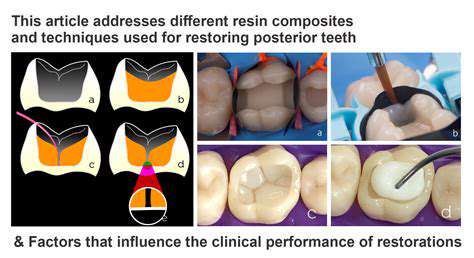

Material selection proves equally crucial. While organic compounds work fine for grocery runs, ceramic or carbon fiber materials become essential for handling the extreme heat generated during track days. These advanced composites maintain friction characteristics even when glowing red-hot, unlike their street-oriented counterparts that fade dangerously when pushed beyond their limits.

Leveraging Racing Technology for Street Performance

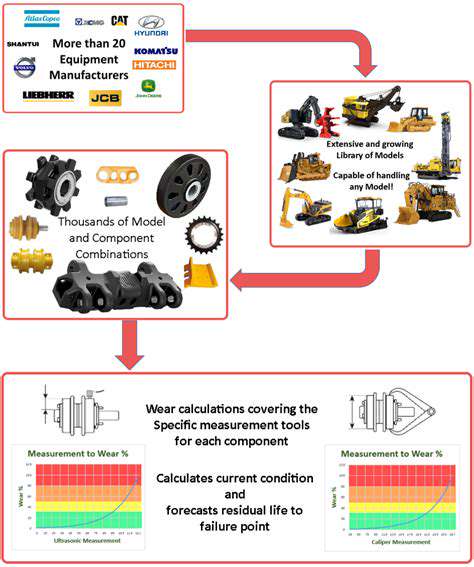

The motorsport world offers valuable lessons for sports car enthusiasts. Twin-plate designs, once exclusive to professional racing, now appear in high-end street applications. These innovative clutches distribute load across multiple friction surfaces, reducing wear while handling tremendous torque. The technology trickle-down means today's aftermarket offers solutions that would have been unimaginable in production cars just a decade ago.

Modern performance clutches represent the perfect marriage of racing durability and street manners. Advanced damper springs absorb driveline shock without compromising immediate power transfer, while lightweight flywheels complement the system by allowing quicker rev matching. The result transforms the driving experience—shifts become crisper, acceleration feels more immediate, and the entire powertrain responds with racetrack precision.

Maintaining High-Performance Clutches for Optimal Longevity

Understanding Clutch Function

A properly functioning performance clutch behaves fundamentally differently than its standard counterpart. The increased clamp load and aggressive friction materials require a more nuanced approach. Mastering the bite point becomes crucial—performance clutches engage within a narrower pedal travel range, demanding precise footwork. This razor-sharp engagement window rewards skilled drivers while punishing sloppy technique.

The performance clutch's role extends beyond simple power transfer. It acts as the critical interface between driver intention and mechanical execution. When balanced perfectly, it provides tactile feedback about traction conditions and power delivery that attentive drivers use to optimize their performance.

Optimal Clutch Engagement Techniques

Performance driving schools emphasize clutch work as much as steering technique. The heel-toe method—simultaneously braking while blipping the throttle during downshifts—becomes mandatory rather than optional with high-performance clutches. This advanced technique maintains driveline balance, prevents rear-wheel lockup, and allows seamless transitions into corners.

Launch control represents another critical skill. Unlike standard clutches that tolerate slipping during starts, performance units demand clean, decisive engagement. The ideal launch finds the sweet spot between bogging down and excessive wheelspin—a balance achieved through practice and intimate familiarity with your specific clutch's characteristics.

Regular Maintenance Practices

Performance clutches require more frequent inspection than standard units. Checking for material glazing—that shiny, hardened surface indicating overheating—should occur after every track event. This condition drastically reduces friction and leads to dangerous slippage if left unaddressed. Specialized resurfacing services can often restore glazed clutches to like-new performance.

Hydraulic systems demand particular attention in performance applications. The higher pedal efforts stress master cylinders and slave cylinders beyond normal parameters. Upgraded components designed for racing often provide the reliability needed for sustained hard use.

Clutch Fluid and Its Importance

Performance driving elevates clutch fluid temperatures dramatically. Standard DOT 3 fluid boils under extreme conditions, causing sudden clutch failure mid-corner. Racing-grade DOT 4 or DOT 5.1 fluids withstand these punishing conditions, maintaining consistent pedal feel lap after lap. The small investment in proper fluid prevents catastrophic—and potentially dangerous—failures.

Bleeding the hydraulic system takes on new importance with performance clutches. Even minor air bubbles compress under high pedal loads, creating a spongy feel that hampers precise modulation. Professional drivers often bleed their systems before every competitive event.

Driving Habits and Clutch Performance

Performance clutches reward mechanical sympathy. Resting your foot on the clutch pedal—even slightly—during spirited driving can overheat the release bearing and lead to premature failure. This common bad habit proves especially destructive with high-performance units where tolerances are tighter and components operate closer to their limits.

After hard use, allowing the clutch to cool properly extends its life significantly. A few minutes of gentle driving before shutdown helps dissipate heat rather than letting it soak into the components. This simple practice can double or triple clutch lifespan in demanding applications.

Identifying Clutch Problems

Performance clutches communicate their condition through subtle changes in feel. A clutch that engages higher in the pedal travel often indicates material wear, while sudden vibration points to pressure plate issues. These early warnings allow proactive replacement before complete failure strands you roadside—or worse, mid-race.

Unusual odors provide another diagnostic clue. The distinctive smell of overheating friction material signals immediate attention is needed. Unlike standard clutches that might recover from occasional overheating, performance units often sustain permanent damage from such events.