Inspecting and maintaining timing belts for optimal performance

List of Contents

- Timing belts synchronize engine components for optimal performance and efficiency.

- Signs of belt wear include ticking noises, difficulty starting, and visual damage.

- Ignoring maintenance leads to severe engine damage and costly repairs.

- Regular inspections can extend a timing belt's lifespan and prevent failures.

- Use high-quality OEM parts for timing belt replacements for optimal compatibility.

- Professional mechanics ensure proper timing belt installation and maintenance.

- Driving conditions and habits can significantly impact timing belt longevity.

Timely maintenance can save money and enhance vehicle resale value.

What is a Timing Belt and Why is it Important?

Understanding the Function of a Timing Belt

In automotive engines, the timing belt acts as the conductor of mechanical harmony. This flexible yet sturdy component links the crankshaft and camshaft, ensuring valves open and close in perfect rhythm with piston movements. When this synchronization falters, engines may misfire or suffer catastrophic damage, making it one of the most mission-critical parts under your hood.

Modern belts combine heat-resistant rubber with reinforcement layers of fiberglass or aramid fibers. While designed for durability, these belts face constant stress from temperature fluctuations and mechanical strain. Most automakers suggest replacements between 60,000-100,000 miles, though urban stop-and-go traffic or extreme climates can accelerate wear.

Signs of Wear and Tear

Listen closely - that rhythmic ticking near the engine front might be your belt crying for help. Other red flags include:

- Engine stuttering during ignition

- Visible cracks resembling dry riverbeds on the belt surface

- Shredded edges or missing teeth along the belt's length

Never ignore these symptoms, especially in interference engines where valve-piston collisions can cause four-figure repair bills. The consequences of delay far outweigh inspection costs.

Consequences of Neglecting Timing Belt Maintenance

A snapped timing belt doesn't just stop your engine - it can turn your cylinder head into a metal junkyard. Repair shops frequently see bent valves, cracked pistons, and scored cylinder walls from these failures. Preventative replacement costs 70-90% less than rebuilding a damaged engine, making it one of the smartest investments in vehicle ownership.

Resale-conscious owners should note: dealerships and private buyers increasingly demand timestamped belt replacement records. A fresh belt installation adds tangible value during negotiations.

How to Inspect Your Timing Belt

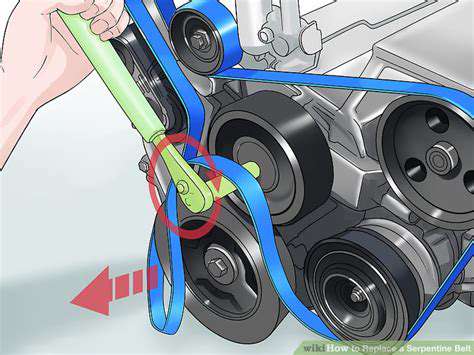

While best left to professionals, savvy owners can perform basic checks:

- Remove the timing cover (consult your manual for location)

- Examine belt surface under bright light

- Check tension by pressing midway between pulleys - should deflect ½ inch

Finding glazed surfaces or embedded debris? Schedule immediate service. Remember - belt failure often occurs without final warning, so don't gamble with visual inspections alone.

Best Practices for Timing Belt Replacement

Smart replacements follow the while you're in there philosophy. Always swap:

| Component | Reason |

|---|---|

| Tensioner pulley | Worn bearings cause uneven wear |

| Water pump | Shared labor costs during belt access |

| Idler pulleys | Prevent future disassembly needs |

OEM belts consistently outperform generic alternatives in fitment and longevity. Aftermarket brands may save $50 upfront but risk premature failure.

Cost of Timing Belt Replacement

Shop rates vary, but expect:

- $200-400 for economy cars

- $600-900 for luxury models

- +$150-300 if replacing water pump

Mechanics often bundle timing jobs with complimentary coolant flushes or belt alignment checks. Pro tip: Schedule replacements during off-peak seasons (late winter) for potential discounts.

Expert Recommendations for Long-Term Care

Extend belt life through:

- Gentle cold starts (avoid revving below operating temp)

- Complete warm-up cycles before heavy loads

- Annual underside cleaning to remove road grime

Track service intervals using your odometer or maintenance app. Every 5,000 miles, ask your mechanic for a belt condition report - most will provide this during oil changes at no extra charge.

Signs of Timing Belt Wear and the Need for Inspection

Common Symptoms Indicating Timing Belt Wear

Your car develops tells before major failures. Watch for:

- Erratic RPM fluctuations at idle

- Oil leaks near timing cover

- Check engine light with cam/crank correlation codes

Performance degradation often manifests gradually - don't dismiss that 10% power loss as normal aging.

Importance of Regular Inspections

Belt lifespan depends on multiple factors:

| Factor | Impact |

|---|---|

| Climate | Dry heat cracks rubber 40% faster |

| Driving Style | Frequent redlining accelerates wear |

| Maintenance | Dirty engines accumulate abrasive debris |

Urban drivers should subtract 15-20% from manufacturer intervals due to constant stop-start cycles.

Consequences of Neglecting Timing Belt Maintenance

The domino effect of belt failure includes:

- Valves freeze in open position

- Pistons strike valve heads

- Connecting rods bend or break

Repair costs skyrocket when multiple systems fail. Partial engine rebuilds often exceed $2,500, while complete replacements can hit $5,000+.

Recommendations for Optimal Timing Belt Lifespan

- Install belt guards against road debris

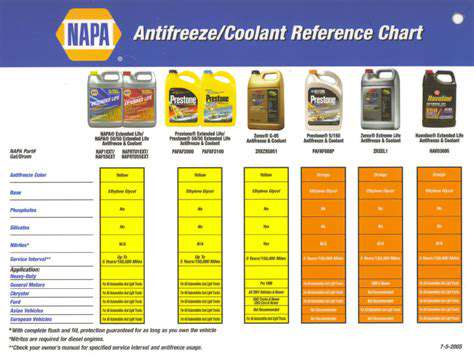

- Use OEM-spec coolant to prevent overheating

- Replace accessory belts simultaneously

Document every service - detailed records help warranty claims and resale negotiations.

Final Thoughts on Timing Belt Care

Treat your timing belt like a parachute - you'll never need it until you desperately do. Proactive replacements offer peace of mind that's worth every penny. Partner with ASE-certified technicians who use laser alignment tools for precision installations.

Inspection Tips for Timing Belts

Understanding Timing Belt Functionality

The unsung hero of engine timing works behind multiple covers. Modern belts feature:

- Hybrid rubber compounds resisting -40°F to 300°F

- Kevlar cords for stretch resistance

- Micro-grooves reducing harmonic vibration

Never judge belt health by exterior appearance alone - internal cord damage often precedes surface cracks.

Signs of Wear and Aging

Use multiple assessment methods:

| Method | Procedure |

|---|---|

| Visual | Check for glazing/cracking |

| Tactile | Feel for hardened rubber |

| Auditory | Listen for whining bearings |

Sudden quietness after belt noise stops often indicates complete tension loss - a critical failure precursor.

Inspection Process: What to Check

Professional inspections evaluate:

- Pulley alignment with laser tools

- Torsional vibration patterns

- Idler bearing smoothness

DIYers: Never rotate the engine backwards during inspection - this can skip teeth and cause immediate damage.

Replacement Guidelines and Best Practices

When replacing:

- Mark old belt/pulley positions for reference

- Clean pulley grooves with brass brushes

- Torque bolts to factory specs (over-tightening warps components)

After installation, manually rotate engine 2-3 full cycles to verify proper engagement before starting.

Common Myths About Timing Belts

Dispelling dangerous misconceptions:

| Myth | Reality |

|---|---|

| Lifetime belts never need replacement | All rubber degrades eventually |

| Lubrication extends belt life | Oils damage rubber compounds |

Truth: Even unused belts expire - replace stored spares after 5 years.

Professional Inspection Services

Certified shops use:

- Endoscopes for hidden area checks

- Stroboscopic timing lights

- Digital tension analyzers

Invest in thermal imaging scans - hot spots reveal misaligned pulleys before visible damage occurs.

Maintenance Practices for Timing Belts

Understanding Timing Belt Functionality

This mechanical metronome does more than sync components - it absorbs vibrations that would otherwise fatigue bearings. Modern designs incorporate:

- Asymmetric tooth profiles reducing noise

- Carbon-black additives resisting UV degradation

- Multi-rib construction for load distribution

Replacement complexity varies wildly - some transverse engines require partial disassembly just for belt access.

Regular Inspection Techniques

Create a maintenance log tracking:

| Metric | Measurement |

|---|---|

| Mileage | Current vs recommended |

| Visual Condition | 1-5 scale (5=new) |

| Tension | Deflection in mm |

Photograph the belt annually - comparison reveals developing issues.

Signs of Timing Belt Wear

Beyond obvious damage, watch for:

- Uneven tooth wear patterns

- Glue separation between layers

- Abnormal pulley groove polishing

Pro tip: Rub a cotton swab along the belt - fibers catching on edges indicate microfractures.

Recommended Replacement Intervals

Adjust factory intervals using this formula:

Base mileage × (Climate factor 0.8-1.2) × (Driving factor 0.7-1.3) = Adjusted replacement mileage

Example: 100k mile base × 1.1 (hot climate) × 0.9 (city driving) = 99k actual

The Importance of Professional Assistance

Certified technicians prevent common installation errors:

- Incorrect tension leading to harmonic vibration

- Misaligned timing marks causing retarded/advanced timing

- Contaminated belt surfaces from improper handling

Ask for before/after timing verification using diagnostic scanners.

DIY vs. Professional Maintenance

Consider these realities before DIY attempts:

| Factor | DIY | Pro |

|---|---|---|

| Tool Investment | $200+ | Included |

| Time Commitment | 4-8 hours | 2-3 hours |

| Error Risk | High | Insured |

For most owners, professional service offers better value considering specialized tools and expertise required.

Future Trends in Timing Belt Technology

The industry evolves with:

- Smart belts with embedded wear sensors

- Ceramic-impregnated compounds

- 3D-printed custom tooth profiles

Hybrid designs combining chain and belt elements may dominate next-gen engines, offering the quiet operation of belts with chain-like durability.