Boosting Horsepower and Torque through Enhanced Efficiency

Introduction to Engine Efficiency

Understanding Engine Efficiency

Engine efficiency refers to how well an engine converts fuel into useful work. The efficiency of an engine can significantly impact both horsepower and torque, as well as overall vehicle performance. Higher efficiency means that more of the energy produced by the combusted fuel is transformed into motion, rather than being lost as heat.

Factors that influence engine efficiency include the design of the engine components, fuel type, and operational parameters. For instance, modern engines often utilize advanced technologies like direct fuel injection and variable valve timing to optimize the combustion process, which in turn enhances efficiency.

Additionally, the size and weight of the engine play a crucial role. A larger engine might produce more power, but if it is not designed for efficiency, it can waste energy and reduce performance. Striking the right balance between engine size, weight, and efficiency is essential for maximizing horsepower and torque.

Taking into account external factors like aerodynamics and drivetrain losses is also important. These factors can detract from the engine's performance, and thus an integrated approach to vehicle design is vital for boosting overall efficiency.

Enhancing Engine Performance through Technology

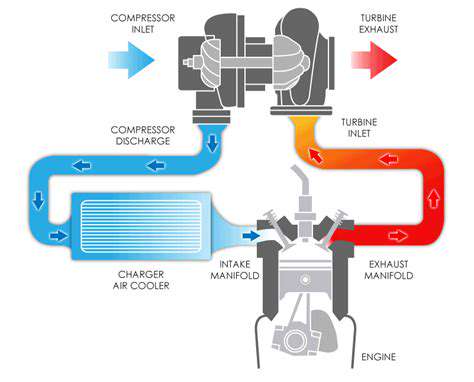

In recent years, technological advancements have led to significant improvements in engine performance. For example, turbocharging has become a popular method for increasing both horsepower and torque without significantly increasing engine size or weight. By forcing more air into the combustion chamber, turbochargers allow for more fuel to be burned, thereby generating additional power.

Moreover, advancements in engine management systems enable more precise control over fuel injection and ignition timing, improving combustion efficiency. These systems use sensors and algorithms to optimize performance in real-time, adapting to varying driving conditions to ensure that the engine operates at its best.

Hybrid systems and electric assistance are also playing a pivotal role in boosting efficiency. By combining traditional internal combustion engines with electric motors, manufacturers are able to enhance torque delivery and increase overall power while maximizing fuel economy.

Lastly, the incorporation of lightweight materials in engine construction contributes to reduced weight and improved efficiency. Engineers are experimenting with composites and aluminum alloys to create engines that maintain strength while shedding excess pounds.

Future Trends in Engine Efficiency and Performance

As we look to the future, the pursuit of engine efficiency and performance is expected to continue evolving. With increasing regulations on emissions and fuel economy, automakers are under pressure to innovate and develop technologies that prioritize efficiency without sacrificing power.

One potential trend is the expansion of alternative fuel sources, such as hydrogen fuel cells and biofuels. These options not only promise to reduce carbon emissions but also present opportunities for improving engine efficiency through unique combustion processes tailored to different fuel types.

Furthermore, the integration of smart technology within vehicles, such as predictive maintenance and real-time performance analysis, offers the potential to optimize engine performance proactively. By analyzing data on driving habits and vehicle conditions, these systems can adjust engine settings for optimal efficiency.

Finally, as electric vehicles become more mainstream, the emphasis on traditional internal combustion engines may shift towards hybrid technologies that unleash the benefits of both electric and gasoline power. This transition will likely redefine how efficiency and performance are perceived in the automotive industry.

The Science Behind Efficiency

The Role of Combustion Efficiency

Combustion efficiency plays a crucial role in how effectively an engine converts fuel into usable energy. When combustion occurs at its optimal level, it ensures that the maximum amount of energy is extracted from each unit of fuel. This results in more power delivered to the drivetrain and ultimately improves the vehicle's overall performance.

Modern engines employ various technologies, such as direct fuel injection and turbocharging, to enhance combustion efficiency. These technologies allow for a more precise control of the air-fuel mixture, leading to a more complete combustion process. By minimizing unburned fuel, these methods also help reduce emissions, making engines greener without sacrificing power.

Another factor that contributes to combustion efficiency is the engine's compression ratio. A higher compression ratio usually leads to more efficient combustion, resulting in an increase in horsepower and torque. Car manufacturers often design engines with specific compression ratios to achieve the perfect balance between efficiency, power output, and engine durability.

In summary, the relationship between combustion efficiency and power output is a fundamental aspect of automotive engineering. By enhancing this efficiency, drivers can experience improved performance and responsiveness in their vehicles, leading to a more engaging driving experience.

Mechanics of Airflow Dynamics

Airflow dynamics within an engine significantly influence its performance capabilities. The ability of an engine to draw in air efficiently can enhance power output and torque. Ensuring that an engine's intake system is designed to optimize air delivery can have profound effects on overall engine efficiency.

Tuning the intake manifold, using larger air filters, and implementing advanced airflow technologies such as variable valve timing can all contribute to improved airflow dynamics. These adjustments allow for a denser mixture of air and fuel, which translates to a more powerful explosion during combustion and thus greater horsepower.

Moreover, exhaust systems also play a critical role in the dynamics of airflow. By reducing back pressure through better exhaust routing and optimizing the design of exhaust headers, an engine can breathe more freely. This reduction in restriction allows the engine to expel exhaust gases quickly and effectively, leading to increased torque and a more responsive throttle.

Ultimately, maximizing the airflow dynamics within an engine not only enhances its performance metrics but also improves fuel efficiency. As manufacturers focus on advanced engineering designs, the gap between high power output and fuel economy continues to narrow, benefiting both the environment and the driver.

Advanced Fuel Technologies

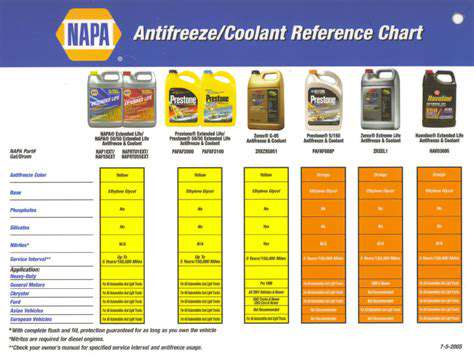

As performance demands increase, so too does the need for advanced fuel technologies that can enhance efficiency. Fuels formulated with higher octane ratings or special additives can allow engines to operate more efficiently under higher pressures and temperatures, leading to better horsepower and torque outputs.

Biofuels and synthetic fuels are gaining popularity as alternatives to traditional fossil fuels. These alternatives often provide better combustion properties and can significantly reduce emissions. Moreover, fuels designed for specific performance characteristics can enhance engine responsiveness and overall performance, making them attractive options for performance-oriented applications.

Today, many fuel manufacturers are also heavily investing in research and development to create fuels that not only promote better energy release but also minimize the negative impacts on engine components. By reducing deposit formation and improving fuel system cleanliness, these advanced fuels help maintain engine efficiency over longer periods, retaining optimum performance.

In essence, the evolution of fuel technologies is a promising pathway to achieving higher horsepower and torque while enhancing overall engine efficiency. As these innovations continue to advance, they provide exciting opportunities for performance enthusiasts and environmentally conscious drivers alike.

The Role of Airflow in Performance

The Importance of Air Intake

Air intake systems play a crucial role in optimizing engine performance. A well-designed air intake allows for a higher volume of air to flow into the engine, which is essential for combustion. The more air that enters the engine, the more fuel can be burned, resulting in increased horsepower and torque.

Additionally, the type of air filter used can significantly impact airflow. High-flow air filters, for example, reduce restriction while still providing adequate filtration, allowing more air to reach the combustion chamber efficiently. This enhancement can lead to noticeable performance gains, especially in high-performance vehicles.

Moreover, the location and design of the air intake system can influence its effectiveness. Cold air intakes, which draw air from outside the engine compartment, can further improve air density and oxygen content, boosting overall performance. Thus, focusing on air intake modifications can be a strategic way to enhance engine efficiency.

Exhaust Flow Dynamics

Just as airflow into the engine is important, the exit path for exhaust gases plays a critical role in performance enhancement. The right exhaust system reduces backpressure, allowing spent gases to exit the engine more freely. This facilitates more efficient engine operation, which can translate into improved horsepower and torque outputs.

Performance exhaust systems are often larger in diameter than stock systems, designed to minimize any restrictions. This change results in better scavenging, allowing the engine to draw in fresh air more effectively for the next combustion cycle. High-performance mufflers and headers can further trim restrictions and enhance the overall exhaust flow.

In essence, optimizing exhaust flow is as vital as enhancing air intake. The balance between these two elements can significantly influence the engine's breathing capabilities, leading to greater efficiency and performance gains. Implementing exhaust modifications is, therefore, an essential aspect of boosting horsepower and torque.

Combustion Efficiency and Fuel Quality

Understanding Combustion Efficiency

Combustion efficiency refers to how effectively a fuel is converted into energy during the combustion process. Higher combustion efficiency means that more of the fuel's energy is utilized for work, leading to increased horsepower and torque. Various factors can influence combustion efficiency, including the fuel type, engine design, and operating conditions. Optimizing these factors is crucial for maximizing engine performance.

To enhance combustion efficiency, automotive engineers often focus on improving the air-fuel mixture, ensuring that the engine receives the optimal ratio for combustion. Techniques such as better fuel injection systems and advanced ignition timing can significantly impact the combustion process, leading to more power output with less fuel consumption.

The Role of Fuel Quality in Performance

Fuel quality plays a pivotal role in the overall performance of an engine. High-quality fuels typically have a higher octane rating, which helps prevent knocking and allows for more aggressive tuning of the engine. This leads to improved performance metrics, including increased horsepower and torque. Additionally, cleaner-burning fuels reduce engine deposits and improve long-term engine health.

Using fuels that contain detergent additives can further enhance combustion efficiency by keeping the fuel injectors and combustion chamber clean. Cleaner components allow for better atomization of the fuel and more complete combustion, which directly improves engine performance and responsiveness.

Technological Advances for Enhanced Efficiency

Recent advancements in engine technology have enabled significant improvements in efficiency and performance. Innovations such as variable valve timing, turbocharging, and direct fuel injection have all contributed to enhanced combustion efficiency. These technologies allow for better control over the engine's operation, optimizing performance across a wide range of driving conditions.

Moreover, advancements in engine management systems have made it possible to finely tune engine parameters in real-time. This adaptability results in improved fuel efficiency and power output, translating into a more enjoyable driving experience without sacrificing performance.

Future Trends in Engine Efficiency

The automotive industry is moving towards the integration of alternative fuels and hybrid technologies, which promise to push the boundaries of horsepower and torque through greater efficiency. Electric and hybrid powertrains can complement traditional combustion engines by providing additional torque and reducing overall fuel consumption.

Moreover, the ongoing development of biofuels and synthetic fuels presents an opportunity to enhance engine performance while also promoting sustainability. These fuels can be designed to provide better combustion characteristics, further improving efficiency and reducing emissions, thus aligning with global efforts to mitigate environmental impact.

Engineering Solutions for Enhanced Efficiency

Understanding Horsepower and Torque

Horsepower and torque are two critical metrics that define the performance of an engine. Horsepower is a measure of how quickly work is done, while torque measures the rotational force produced by the engine. In simple terms, horsepower reflects the engine's speed and output capacity, whereas torque indicates its ability to propel a vehicle from a standstill or to carry heavy loads.

Improving these metrics involves enhancing the efficiency of the engine components, fuel delivery systems, and exhaust flow. By optimizing how an engine produces power, engineers can achieve better performance without necessarily increasing the size of the engine or its fuel consumption.

Innovative Engineering Solutions

To boost horsepower and torque, engineers employ various innovative solutions. Turbochargers and superchargers, for instance, compress air entering the engine, allowing for more fuel and oxygen to be combusted, which increases power output. Additionally, performance tuning of the engine control unit (ECU) can refine fuel-to-air ratios and ignition timing, leading to significant improvements in efficiency.

Moreover, advanced materials and designs in parts like pistons, camshafts, and exhaust manifolds play a crucial role. Lightweight materials can reduce engine load while optimizing airflow throughout the system can enhance combustion efficiency, further benefiting overall engine performance.

The Role of Fuel Quality and Maintenance

Fuel quality is another essential factor in maximizing horsepower and torque. Higher-octane fuels improve engine performance by enabling higher compression ratios without knocking. This not only boosts efficiency but also ensures that the engine runs cooler, extending its lifespan.

Regular maintenance plays a crucial role in keeping an engine running at peak efficiency. Simple tasks, such as replacing air filters, ensuring proper tire pressure, and regular oil changes, can significantly impact an engine's performance. By maintaining components in optimal condition, vehicle owners can experience enhanced horsepower and torque while enjoying more reliable operation.

The Impact of Weight Reduction

Understanding Weight Distribution

Weight distribution refers to how the weight of a vehicle is spread across its axles. This factor significantly influences a vehicle's overall performance, particularly in acceleration and handling. A well-balanced distribution can enhance traction and stability during high-speed maneuvers. For instance, in sports cars, having a lower center of gravity may lower the risk of rollovers and improve cornering performance. Evaluating weight distribution is crucial for optimizing a vehicle’s horsepower and torque.

It is important to consider the effects of weight distribution on specific components of the vehicle. Heavier components situated away from the center can adversely affect handling and increase the vehicle's inertia. This is particularly detrimental in performance-driven applications. Engineers often strive for a near-perfect weight distribution to maximize efficiency.

Modern engineering solutions aim at tweaking weight distribution through careful placement of heavier components. Techniques such as relocating the battery or using lightweight materials help in achieving a more balanced load. Every reduction in unnecessary weight can significantly improve the torque-to-weight ratio, leading to better overall performance. Proper attention to weight distribution can yield dividends in not just everyday driving but also competitive racing scenarios.

When assessing weight distribution, one must also consider the driving conditions. Different terrains can shift the effectiveness of a vehicle's weight distribution. For instance, off-roading demands a different configuration compared to track racing. A thoughtful approach ensures optimal performance across various conditions.

In conclusion, weight distribution is a pivotal aspect of automotive design that directly correlates with horsepower and torque optimization. Its proper management allows for a balance between speed, stability, and handling.

Advanced Material Use

The choice of materials in vehicle construction plays a vital role in weight reduction. Traditional materials such as steel have been standard for many years. However, advancements in technology have ushered in the feasibility of using lightweight alternatives like carbon fiber and aluminum. Such materials not only reduce overall weight but also contribute to enhanced structural integrity.

By employing lightweight materials strategically, manufacturers can achieve significant decreases in weight without sacrificing safety. This reduction can translate into faster acceleration and better fuel efficiency. Many race car constructors utilize these materials to push the boundaries of performance engineering. The shift to advanced materials has reshaped the industry, prioritizing both performance and sustainability.

Another aspect of advanced materials is their manufacturability and cost-effectiveness. While carbon fiber has clear performance benefits, its cost can be prohibitive for mass market vehicles. As technology matures, more cost-effective options are emerging, making lightweight materials accessible across different vehicle categories. This trend signals a future where weight reduction strategies become standard practice in automotive manufacturing.

It is also worth noting the environmental implications of using lightweight materials. By improving fuel efficiency through weight reduction, vehicles can lower their carbon footprint. This aligns with the increasingly eco-conscious approach to automotive design and production. As such, the use of advanced materials is likely to become an industry standard in the quest for greener vehicles.

In summary, advanced materials are essential for achieving weight reduction in vehicles, leading to enhanced horsepower and torque. The benefits of these materials extend beyond performance, fostering sustainability in the automotive industry.

Impact on Engine Performance

Reducing the overall weight of a vehicle impacts engine performance in multifaceted ways. For one, it lessens the load that the engine must work against, translating to quicker accelerations. The reduction in weight can also lead to improved fuel efficiency, as the engine expends less energy to propel the vehicle forward. This added efficiency allows for better optimization of both horsepower and torque.

Engine tuning plays a significant role in maximizing performance alongside weight reductions. Engineers often recalibrate engine parameters to account for the lighter construction of the vehicle. This can result in a more responsive throttle and quicker gearbox shifts. The synergy between weight reduction and engine tuning can yield dramatic improvements in a vehicle's performance profile.

Additionally, the relationship between vehicle weight and power-to-weight ratio is crucial when considering performance outcomes. A lighter vehicle with the same engine as a heavier counterpart will usually outperform it. In competitive racing contexts, this could be the difference between winning and losing. Consequently, many racing classes impose stringent weight limits to level the playing field.

Moreover, weight reduction can extend the lifespan of an engine by reducing the stress placed on its components. Less weight can mean less friction and wear, resulting in lower maintenance costs. Optimizing weight can, therefore, bring about not just performance benefits, but also long-term economic advantages for vehicle owners.

In conclusion, the interplay between weight reduction and engine performance is vital for achieving enhanced horsepower and torque in vehicles. This complex relationship ultimately determines how well a vehicle performs under various conditions.