The importance of proper torque in wheel installation

Why is Wheel Torque So Important?

Understanding the Fundamentals of Wheel Torque

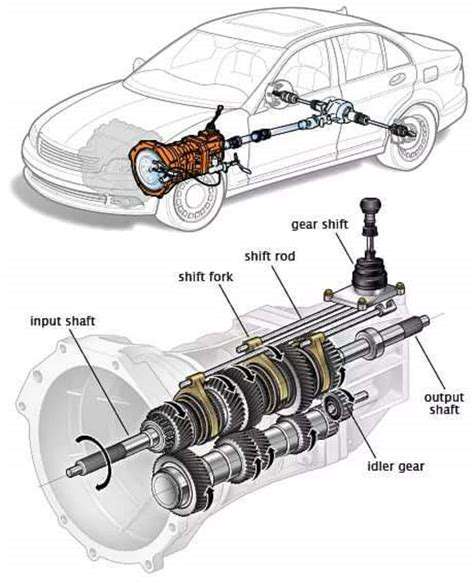

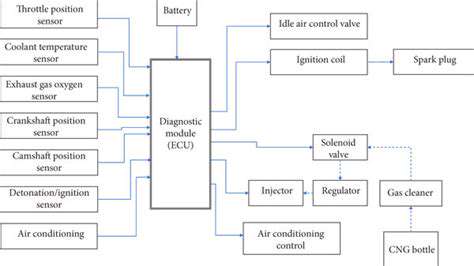

Wheel torque, a crucial aspect of vehicle performance and safety, essentially represents the twisting force applied to the wheels. This force, generated by the engine's powertrain, is directly translated into rotational motion, propelling the vehicle forward or enabling it to ascend inclines. Understanding the magnitude and characteristics of this torque is paramount for optimizing vehicle efficiency and driving experience.

Essentially, wheel torque is the driving force behind a vehicle's movement. It's the interaction between the engine's output and the wheels that dictates acceleration, handling, and overall vehicle dynamics. A deep understanding of this principle is vital for those seeking to optimize their vehicle's performance and ensure its safe operation.

Impact on Acceleration and Performance

The amount of wheel torque directly influences a vehicle's acceleration capabilities. A higher wheel torque output translates to quicker acceleration, allowing the vehicle to rapidly gain speed. This is particularly noticeable when accelerating from a standstill or merging onto a highway.

A robust wheel torque output is essential for impressive performance in various driving scenarios. From quick getaways to maintaining speed on the highway, the torque generated at the wheels is a driving force behind a vehicle's ability to respond dynamically to the driver's input.

Influence on Handling and Traction

Wheel torque is not solely about acceleration; it also significantly affects handling. Adequate torque enables a vehicle to maintain stability during turns and maneuvers. A deficiency in torque can lead to loss of traction, particularly on slippery surfaces or when cornering aggressively.

Sufficient wheel torque is fundamental to maintaining vehicle stability and traction during various driving conditions. Proper torque management is essential for maintaining control and preventing skidding, especially in challenging driving environments.

Role in Hill Climbing and Towing Capacity

Vehicles with sufficient wheel torque are better equipped to ascend steep hills. The torque acts against the force of gravity, enabling the vehicle to overcome the incline. This is particularly crucial for vehicles that frequently navigate hilly terrain or need to tow heavy loads.

The torque available at the wheels directly correlates with a vehicle's ability to climb hills and tow heavy loads. A higher torque output ensures the vehicle can effectively overcome the resistance imposed by the incline and the weight being towed. This capability is essential for many off-road and commercial vehicles.

Maintenance and Troubleshooting Considerations

Understanding how wheel torque impacts vehicle performance is crucial for effective maintenance and troubleshooting. Problems with the engine, transmission, or drivetrain can significantly affect the amount of torque delivered to the wheels. By understanding these connections, drivers can identify potential issues early on, leading to timely repairs and preventing larger problems.

Regular maintenance and prompt troubleshooting are essential for maintaining optimal wheel torque. Checking fluids, inspecting belts and hoses, and ensuring proper lubrication can help prevent torque-related issues, maintaining the vehicle's performance and safety.

The Science Behind Torque Specifications

Understanding Torque

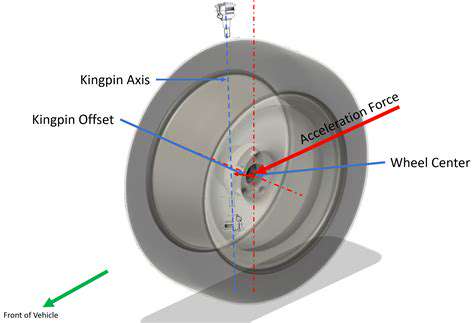

Torque, in the context of wheel installations, refers to the rotational force applied to a fastener, such as a lug nut. This force is crucial for ensuring a secure and reliable connection between the wheel and the vehicle's axle. Understanding the science behind torque specifications is paramount to preventing premature wheel loosening, potential accidents, and ensuring the longevity of the vehicle's mechanical components.

Essentially, torque is the twisting force that causes rotation. Different fasteners, like lug nuts, require specific torque values to achieve optimal clamping force. This clamping force is directly related to the secure hold of the wheel and its ability to withstand the stresses of driving.

The Role of Tightening Sequences

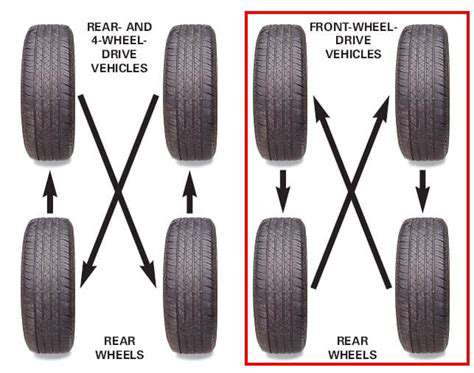

Proper tightening sequences are just as critical as the torque specifications themselves. A common mistake is to tighten lug nuts in a haphazard manner. A systematic approach, typically starting with a few turns, then moving to the next lug, and repeating this process several times, ensures even clamping force distribution across all the lug nuts. Using a crisscross pattern or a star pattern are common methods to achieve this even distribution.

The Impact of Material Properties

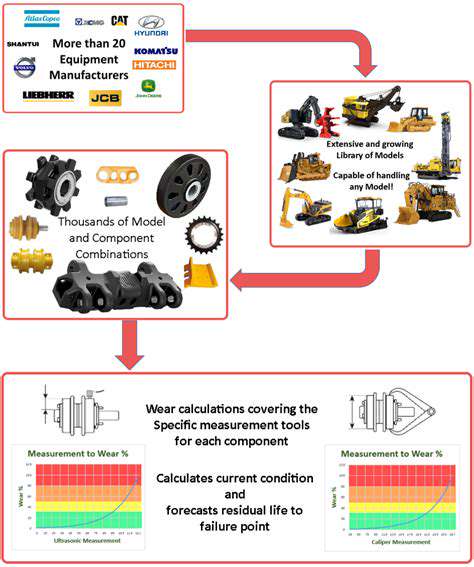

The material properties of both the fastener and the component being fastened play a crucial role in determining the optimal torque specification. Different metals and alloys exhibit varying degrees of strength and elasticity. For instance, a harder alloy requires a higher torque value to achieve the same clamping force compared to a softer material. Understanding these material characteristics is essential for selecting the appropriate torque settings.

Factors Affecting Torque Specifications

Several factors influence the precise torque specification required for a given application. These include the type of fastener (e.g., lug nut material and size), the type of wheel (e.g., alloy, steel, or other material), the vehicle's design, and environmental conditions. These factors combine to determine the ideal clamping force needed to prevent loosening under various driving conditions, including acceleration, braking, and cornering.

Consequences of Incorrect Torque

Insufficient torque can lead to premature wheel loosening, potentially causing the wheel to come off while driving, which is a serious safety hazard. Conversely, excessive torque can damage the wheel studs or lug nuts, resulting in the need for replacements and possible structural damage. Accurate torque application is therefore critical for both safety and the longevity of the vehicle's components. Incorrect torque application can also lead to uneven tire wear and potentially create vibration problems.

Importance of Using a Torque Wrench

A torque wrench is an indispensable tool for ensuring precise torque application. It provides a direct measure of the rotational force applied to the lug nuts, enabling technicians and DIY enthusiasts to achieve the exact torque specification recommended by the vehicle manufacturer. Using a torque wrench eliminates the guesswork and ensures that the lug nuts are tightened to the optimal level without over-tightening. This prevents damage to the components and ensures long-term safety and reliability.

Consequences of Improper Torque

Consequences of Damaged Fasteners

Improper torque application can lead to a variety of issues with fasteners, including stripped threads, deformed heads, and ultimately, failure. This can result in catastrophic equipment malfunction and potential safety hazards. Furthermore, the damage to the fasteners themselves often necessitates costly replacement and downtime, as well as potentially impacting the structural integrity of the assembly.

Structural Integrity Issues

Insufficient torque can lead to loose connections, allowing components to shift or vibrate excessively. This compromises the overall stability of the structure, leading to potential deformation or even collapse. Over-torquing, on the other hand, can cause material fatigue and stress concentration, creating weak points and increasing the likelihood of failure.

Equipment Malfunction

Machines and equipment reliant on properly secured components can experience significant disruptions due to improper torque. Machines that depend on tight connections to function correctly can fail completely, leading to production delays, repairs, and potential financial losses. The consequences can range from minor malfunctions to complete system failures.

Safety Hazards

Improper torque can create dangerous conditions for workers. Loose connections can cause components to detach or vibrate violently, leading to potential injury. Moreover, failure of critical connections in machinery or structures can lead to serious accidents and injuries. This underscores the importance of precise torque application and regular inspections to ensure safety.

Increased Maintenance Costs

Regular maintenance and repairs are significantly impacted by improper torque. Frequent replacements of damaged fasteners, and the need for more extensive repairs due to structural issues, quickly escalate maintenance costs. This can lead to substantial financial burdens for organizations and individuals alike.

Reduced Efficiency and Productivity

Machines and systems that operate with improperly torqued components often experience reduced efficiency and productivity. Downtime due to repairs or replacements of damaged components directly impacts production output and profitability. The cascading effect of these issues can significantly reduce overall operational effectiveness, leading to a decrease in output and revenue.

Environmental Impact

The need for frequent replacements of damaged components due to improper torque can lead to a substantial increase in waste generation. This can have a negative impact on the environment, contributing to landfill waste and potentially impacting local ecosystems. Furthermore, the production and disposal of new components can also add to environmental concerns.