Common issues with CVT transmissions and how to address them

Checking for Slipping

One of the most frequent CVT transmission problems involves slipping, where drivers experience a sudden loss of power or sluggish acceleration. This happens when the transmission fails to properly transfer engine power to the wheels, creating a sensation similar to the engine straining to keep up with speed demands. When you notice these symptoms, particularly during uphill climbs or acceleration, immediate professional inspection becomes essential. Left unchecked, slipping can escalate into more serious mechanical failures affecting the entire drivetrain system.

Monitor your vehicle's acceleration response carefully. A properly functioning CVT should deliver smooth, linear power delivery. Any instances of hesitation, jerky movements, or engine revving without speed increase clearly indicate potential transmission slippage that requires attention.

Unusual Noises

Unlike conventional automatic transmissions, CVT units often produce distinctive sounds that may signal trouble. These auditory warnings can include high-pitched whining during low-speed operation or more concerning grinding noises that suggest serious internal damage. Early detection of these sounds can mean the difference between simple maintenance and expensive transmission overhauls.

Pay particular attention to noise variations during different driving scenarios - acceleration, deceleration, and idle conditions all provide valuable diagnostic information. A skilled technician can accurately interpret these sounds to determine the necessary repairs before minor issues become major problems.

Rough Shifting or Shifting Issues

The hallmark of a healthy CVT transmission is its seamless, almost imperceptible gear ratio changes. When you begin noticing rough transitions, hesitation between gears, or difficulty initiating movement, these represent clear signs of internal component wear. Such symptoms typically result in a noticeably degraded driving experience that demands prompt attention.

Document how your transmission behaves across various operating conditions - from complete stops to highway cruising speeds. This detailed record helps mechanics accurately diagnose specific issues and recommend appropriate solutions.

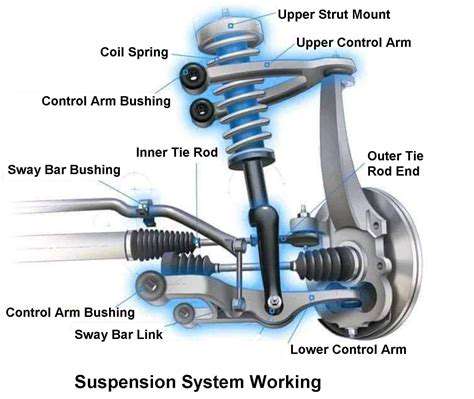

Vibration and Shaking

While often dismissed as normal vehicle behavior, unusual vibrations through the steering wheel, pedals, or entire chassis frequently indicate CVT transmission distress. These vibrations might stem from component misalignment, excessive wear, or internal transmission faults. Regardless of intensity, persistent vibrations warrant professional evaluation to prevent potential system failures.

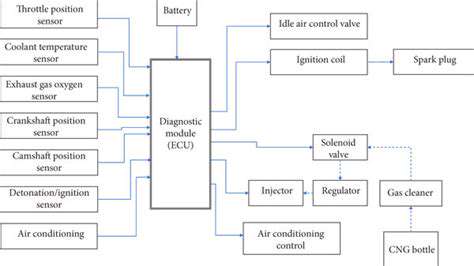

Check Engine Light and Diagnostic Codes

When your dashboard's check engine light illuminates, it serves as your vehicle's direct communication that something requires attention. Modern vehicles store specific diagnostic trouble codes that precisely identify transmission-related issues, making professional code retrieval essential for accurate diagnosis. These codes often reveal problems before they become apparent through driving symptoms, allowing for proactive repairs.

Never ignore warning lights, as what begins as a minor issue can rapidly develop into major transmission damage requiring extensive repairs. Early intervention based on diagnostic codes can save significant time and money.

Addressing CVT Slippage: A Common CVT Transmission Complaint

Understanding CVT Slippage

CVT slippage represents one of the most frequent driver complaints with continuously variable transmissions. This condition manifests as interrupted power delivery during acceleration, creating a noticeable gap between engine response and vehicle movement. Drivers accustomed to traditional automatics often find this behavior particularly disconcerting, as CVTs typically provide smoother operation when functioning properly.

While not every instance of slippage indicates imminent failure, it consistently serves as an important warning sign that warrants professional evaluation. Understanding the difference between normal CVT operation and genuine slippage helps vehicle owners make informed maintenance decisions.

Potential Causes of CVT Slippage

Multiple factors contribute to CVT slippage, ranging from routine wear to complex mechanical failures. The specialized belt and pulley system represents the most vulnerable component, while hydraulic control issues and transmission computer malfunctions also rank as common culprits. Perhaps most importantly, improper fluid levels or incorrect fluid specifications frequently underlie slippage problems, highlighting the critical importance of using manufacturer-approved fluids.

Driving style significantly impacts CVT longevity. Aggressive acceleration and abrupt braking place excessive stress on the transmission system, accelerating wear that leads to slippage. Consistent, gentle operation combined with regular maintenance provides the best defense against premature CVT issues.

Diagnosing CVT Slippage

Accurate diagnosis requires methodical observation of slippage characteristics. Note specific conditions when slippage occurs - during initial acceleration, at certain speeds, or under particular load conditions. This information proves invaluable to technicians attempting to isolate the root cause. Modern diagnostic equipment can read transmission performance data in real-time, providing concrete evidence of slipping behavior.

A comprehensive inspection should include fluid condition analysis, belt and pulley examination, and hydraulic system testing. Advanced diagnostic scans can reveal electronic control issues that might escape visual inspection.

Maintenance and Prevention of CVT Slippage

Preventative maintenance forms the foundation of CVT longevity. Strict adherence to manufacturer-recommended service intervals for fluid changes and system inspections dramatically reduces slippage likelihood. Using precisely specified transmission fluid cannot be overemphasized, as even minor deviations can significantly impact performance and durability. Thoughtful driving habits complement proper maintenance, with smooth acceleration and anticipation of traffic flow reducing unnecessary transmission stress.

Repair Options and Costs

CVT repair costs vary dramatically depending on the underlying issue. Simple fixes like fluid replacement or belt adjustment prove relatively inexpensive, while complete transmission rebuilds or replacements carry substantial costs. Obtaining multiple professional assessments before committing to major repairs helps ensure appropriate, cost-effective solutions.

When facing significant repair bills, consider the vehicle's overall condition and value. Sometimes, preventive maintenance on an older vehicle makes more economic sense than extensive transmission work, while newer models often justify the investment in proper repairs.

Fluid Management: The Cornerstone of CVT Transmission Health

Proper Fluid Levels and Quality

Maintaining precise fluid levels stands as the single most important factor in CVT transmission care. Both underfilling and overfilling create serious operational problems, while using incorrect fluid types guarantees premature failure. Always consult your owner's manual for specific fluid recommendations and checking procedures, as these vary significantly between manufacturers. The specialized fluids required for CVTs differ substantially from conventional automatic transmission fluids, making proper selection absolutely critical.

Fluid Viscosity and Temperature

CVT fluid viscosity changes dramatically with temperature fluctuations, directly impacting transmission performance. Extreme cold thickens the fluid, potentially causing sluggish operation during warm-up, while excessive heat thins the fluid, reducing its protective qualities. Monitoring operating temperatures and ensuring adequate cooling system function helps maintain optimal viscosity across all driving conditions.

Regular Fluid Changes and Maintenance

CVT fluid degrades over time, losing its protective additives and accumulating contaminants. Following the manufacturer's recommended change intervals represents the best insurance against premature transmission wear. Neglecting fluid changes represents one of the most common - and most expensive - mistakes CVT owners make. Consider more frequent changes if you regularly drive in severe conditions like extreme temperatures, heavy traffic, or mountainous terrain.

Impact of Driving Habits on Fluid Management

Your driving style directly affects CVT fluid lifespan. Aggressive operation generates excessive heat that breaks down fluid properties, while gentle acceleration and anticipation of traffic flow promote cooler operation. Allow adequate warm-up time in cold weather, as cold fluid provides inferior lubrication until reaching optimal operating temperature.

Importance of Proper Cooling System

The transmission cooling system works tirelessly to maintain proper fluid temperatures. Clogged coolers, malfunctioning thermostats, or low coolant levels all contribute to overheating that can destroy a CVT in short order. Include cooling system inspections in your regular maintenance routine to prevent catastrophic failures.

Troubleshooting Fluid-Related Issues

Recognizing early warning signs of fluid problems can prevent major repairs. Discolored or burnt-smelling fluid, increased transmission noise, or erratic shifting all suggest fluid-related issues. Address these symptoms immediately through professional inspection and appropriate fluid service to avoid progressive damage.

When to Seek Professional Help: Recognizing the Need for Expert Diagnosis

Recognizing Symptoms of Potential Issues

CVT transmission problems often begin subtly before progressing to complete failure. Early symptoms like intermittent slippage, occasional strange noises, or slight hesitation might seem minor but frequently indicate developing issues. Documenting these early warnings helps technicians identify patterns that point to specific problems. Waiting until symptoms become severe often multiplies repair costs and may lead to additional damage.

Understanding the Importance of Timely Intervention

The relatively complex design of CVT transmissions means small problems can quickly escalate. What begins as a minor fluid leak or slight belt wear can rapidly progress to complete transmission failure if left unaddressed. Early diagnosis and repair not only saves money but often prevents the need for complete transmission replacement.

When DIY Measures Aren't Enough

While some maintenance tasks like fluid checks can be performed by owners, most CVT issues require professional diagnosis and repair. The specialized tools and knowledge needed for proper CVT service make professional assistance essential for anything beyond basic maintenance. Attempting complex repairs without proper training often leads to additional damage and higher repair costs.

Assessing the Severity of Symptoms

Evaluate transmission symptoms based on frequency and intensity. Occasional mild symptoms might warrant monitoring, while consistent or severe issues demand immediate professional attention. When in doubt, err on the side of caution - the cost of diagnosis pales in comparison to major transmission repairs.

Seeking Second Opinions for Major Repairs

For significant proposed repairs, especially those involving complete transmission replacement, obtaining multiple professional opinions proves invaluable. Different shops may identify alternative solutions or provide varying cost estimates. This due diligence helps ensure you receive appropriate, cost-effective service.

Considering the Impact of Vehicle Value

When facing expensive transmission repairs, consider your vehicle's overall value and condition. Sometimes investing in a new vehicle makes more financial sense than extensive repairs on an older model. A trusted mechanic can help evaluate this decision based on your specific circumstances.

Recognizing Emergency Situations

Certain symptoms demand immediate attention, including complete loss of drive, severe noises, or burning smells. These indicate potentially catastrophic failures in progress. In such cases, immediately stopping operation and arranging for professional assistance can prevent additional damage and safety hazards.