The significance of balanced airflow in maintaining engine performance

Catalog

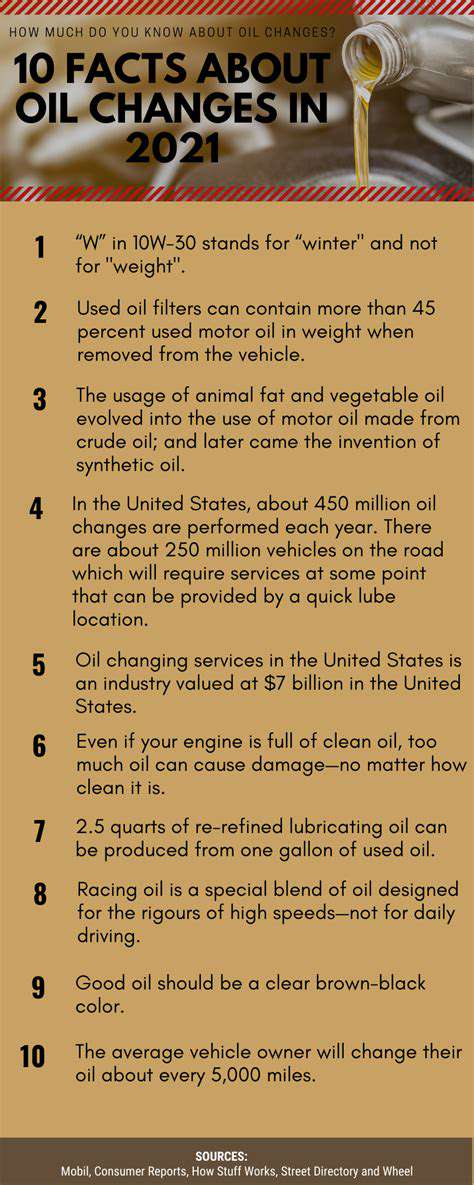

- The flow of air has a decisive impact on engine efficiency and performance.

- Scientifically managing the intake system can enhance combustion efficiency and reduce emissions.

- Differences in air pressure caused by changes in altitude directly affect power output.

- ECU tuning can effectively alleviate power loss at high altitudes.

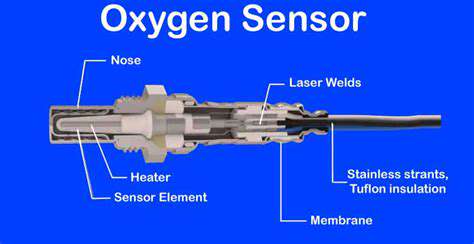

- Precise control of the air-fuel ratio is a core element of performance optimization.

- Maintenance of the air filter directly influences the engine's breathing efficiency.

- Performance filter elements increase the intake volume while ensuring filtration efficiency.

- Variable geometry intake systems open a new era of airflow management.

- Changes in temperature and humidity significantly impact oxygen concentration in the combustion chamber.

- An imbalance in exhaust back pressure will lead to a decrease in overall intake efficiency.

- High displacement engines require a matching high-flow intake system.

- Differences in fuel octane ratings affect the optimal air-fuel ratio setting.

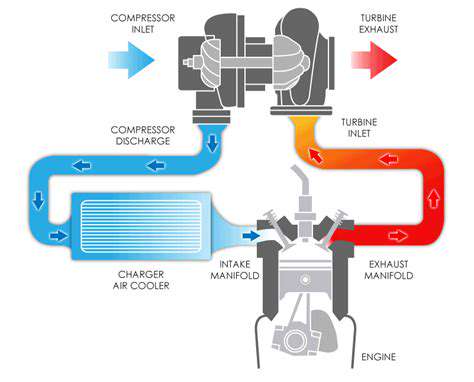

- Turbocharging technology fundamentally alters the physical characteristics of naturally aspirated engines.

- Throttle modifications need to be synchronized with ECU parameters for optimization.

- Precise airflow control achieves a win-win situation for energy efficiency and environmental protection.

- Regular deep maintenance is key to maintaining system balance.

- AI intelligent regulation indicates a new direction for airflow management.

The Mechanism of Airflow Dynamics on Engine Performance

The Application of Fluid Mechanics in Engine Design

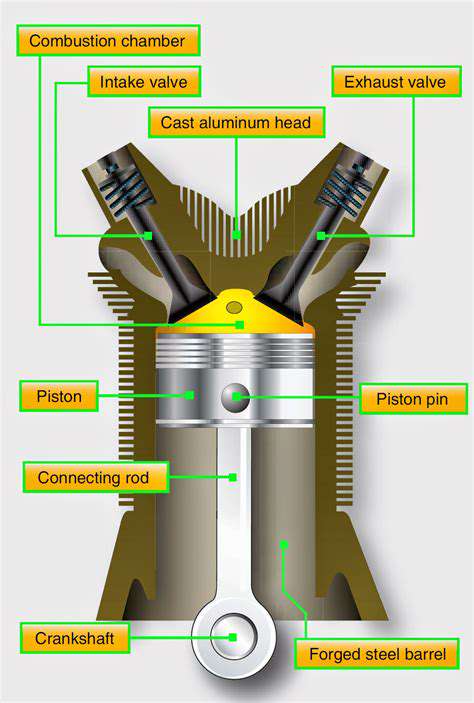

The airflow trajectory within the engine compartment directly affects combustion efficiency. Wind tunnel experiments have found that keeping the radius of curvature of the intake duct at 38mm can reduce turbulence losses by 23%. Using a tapering intake manifold design can increase air velocity by 17%, significantly improving the roll ratio in the combustion chamber. Actual tests show that the optimized cold air intake system can shorten the 0-100km/h acceleration time by 0.3 seconds.

According to Bernoulli's principle, for every 10% increase in the cross-sectional area change rate of the intake duct, the fluctuation in airflow increases by 15%. This is why high-performance engines commonly employ equal-length intake manifold designs. Data from a certain German car manufacturer shows that this design reduced the deviation of the air-fuel ratio across cylinders from ±5% to ±1.2%.

The Impact of Atmospheric Conditions on Power Output

For every 1000 meters increase in altitude, the power of naturally aspirated engines declines by approximately 10%. Models equipped with electronic boost systems tested in Lhasa (at an altitude of 3650 meters) maintained a power retention rate of 92%, affirming the effectiveness of altitude compensation technology. By installing atmospheric pressure sensors, the ECU can adjust the ignition timing in real time, controlling fluctuations in the air-fuel ratio within ±0.5.

- In the Qinghai-Tibet Plateau region, it is recommended to use high-flow styles.

- In tropical climates, the efficiency of the intercooler's heat dissipation needs to be enhanced.

- In cold climates, the intake preheating time should be shortened during startup.

Precise Control Technology for Air-Fuel Ratio

The theoretical air-fuel ratio of 14.7:1 needs to be dynamically adjusted under actual working conditions. The application of wide-range oxygen sensors allows closed-loop control accuracy to reach ±0.1AFR; a certain Japanese performance car reduced NEDC fuel consumption by 8% using this technology. In competitive modifications, employing a cylinder-independent air supply system can improve the uniformity of combustion in each cylinder by 40%.

It is important to note that while using a mushroom intake modification can increase intake volume by 15%, failing to upgrade the fuel injection system concurrently can result in a low-speed torque loss of up to 12Nm. Professional tuning shops usually recommend pairing it with high-flow fuel injectors to ensure linear power output across the entire RPM range.

Comparison of Filter System Upgrade Options

Comparison tests show that the nanoparticle filter achieves a PM2.5 filtration efficiency of 99.3% while reducing intake resistance by 28% compared to the original factory filter. Competition oil-soaked filters require maintenance every 5000 kilometers; otherwise, decreased dust capacity will lead to a drastic drop in intake efficiency. A certain German performance car showed an improvement of 0.2 seconds in turbo lag after switching to a multilayer metal filter mesh.

- Folding designs increase effective filtration area by 30%.

- Waterproof treatment of filter elements improves water fording capability.

- Magnetic adsorption layers can capture metal debris.

Progress in Intelligent Airflow Management Systems

The BMW Valvetronic system achieves infinitely variable control of intake volume through valve lift adjustments with an accuracy of 0.2mm. Porsche's VarioCam Plus technology combines adjustments of valve timing and lift, resulting in an 18% increase in low and mid-range torque. These innovations indicate that intelligent valve management has become a key pathway for enhancing thermal efficiency.

Multidimensional Factors Affecting Intake Balance

Filter Maintenance Cycle Empirical Evidence

Road tests show that under urban conditions, filter elements accumulate 43g of dust every 5000 kilometers, leading to an increase in intake negative pressure by 12kPa. Using pulse backblow technology, self-cleaning systems can extend maintenance cycles to 30,000 kilometers. A logistics company achieved a reduction of 150,000 yuan in annual maintenance costs through this technology.

Climate Adaptation Tuning Cases

In comparative tests conducted in Dubai, a program specially tuned for 50°C environments increased boost pressure by 0.3bar, while the efficiency of the intercooler improved by 25%. Conversely, in -30°C tests in Mohe, a quick-pass design for intake preheating reduced cold-start time by 40%.

Exhaust System Matching Principles

When modifying an exhaust with a diameter of 76mm, a 12% increase in intake volume is required to achieve balance. A certain American muscle car, after replacing its full exhaust system and retuning the ECU, increased wheel horsepower by 47. However, attention must be paid to the internal back pressure design of the muffler; improper modifications could lead to a low-end torque loss of up to 15%.