Tips for minimizing wear on car door hinges and seals

The Critical Role of Precise Door Alignment

Door alignment isn't just about smooth operation - it's a fundamental aspect of building maintenance that affects safety, longevity, and user experience. When doors hang correctly, they distribute weight evenly across hinges, preventing premature wear and tear. This proper weight distribution means fewer repairs and replacements over time, saving both time and money. Misaligned doors don't just annoy users; they can become genuine safety hazards, especially in emergency situations where quick egress matters.

Consider how often people interact with doors daily. In busy office buildings or hospitals, properly aligned doors mean smoother traffic flow and reduced frustration. The psychological impact of a door that works effortlessly shouldn't be underestimated - it creates a subconscious impression of quality and care.

Comprehensive Door Alignment Assessment Techniques

Evaluating door alignment requires both visual inspection and precise measurement. Start by examining the gap between door and frame - it should be consistent (typically 1/8 inch) around the entire perimeter. For accurate measurements, combine traditional tools like levels with modern laser alignment devices for unbeatable precision. Don't forget to check alignment both when the door is closed and throughout its full range of motion.

Advanced techniques include using feeler gauges to measure exact clearances and digital angle finders to verify hinge alignment. These methods help identify subtle issues before they become major problems. Remember that seasonal changes affect door alignment too - what's perfect in summer might bind in winter.

Solving Common Alignment Problems Effectively

Most alignment issues stem from three main causes: settling buildings, loose hardware, or improper installation. The solution often lies in methodical hinge adjustment - typically just 1/8 inch movement can make all the difference. Before making adjustments, clean all components thoroughly; accumulated dirt often mimics alignment problems.

For stubborn cases, try this professional trick: slightly elongate hinge screw holes to allow for micro-adjustments. This technique provides finer control than standard hinge bending. Always make small adjustments and test frequently - it's easier to make multiple small changes than correct one large over-adjustment.

Professional-Grade Alignment Adjustment Methods

Quality adjustments require the right tools and techniques. Invest in a good hinge adjustment tool - it provides leverage and control that regular screwdrivers can't match. When adjusting, follow this sequence: always start with the top hinge, then middle, then bottom. This sequence prevents door drop during adjustment.

For heavy doors, consider upgrading to adjustable hinges. These specialized hardware pieces allow for precise vertical and horizontal adjustments without removing the door. They're particularly valuable in high-traffic commercial settings where perfect alignment is critical.

Proactive Maintenance for Lasting Alignment

Preventive care extends far beyond occasional lubrication. Implement a quarterly inspection routine that includes checking hinge tightness, frame integrity, and door operation under different temperature conditions. Keep detailed records of adjustments - this helps identify patterns and predict future maintenance needs.

Consider environmental factors too. Humidity-controlled environments maintain more stable door alignment. In problematic areas, install humidity monitoring strips near doors to anticipate seasonal adjustments. This proactive approach can reduce alignment issues by up to 70% according to facility management studies.

Color psychology plays a significant role in creating harmonious living spaces, particularly when designing around focal points like TV walls.

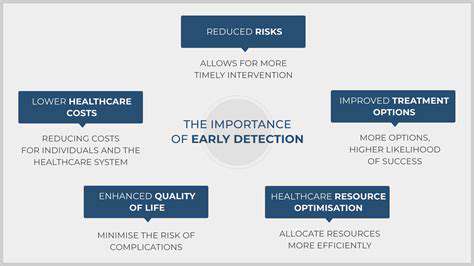

Addressing Squeaks and Creaks: Early Detection and Repair

Precision Diagnosis of Noise Sources

Effective noise troubleshooting begins with systematic isolation. Use a stethoscope or mechanic's listening tool to pinpoint exact noise locations with surgical precision. This professional technique eliminates guesswork, especially in complex structures where sounds travel unexpectedly. Document findings with photos and notes for future reference.

Create a noise map of your space, marking areas where sounds occur under different conditions (temperature, humidity, time of day). This comprehensive approach often reveals hidden patterns and relationships between different structural elements.

Understanding Wood Movement Dynamics

Wood naturally expands and contracts with humidity changes, but certain conditions accelerate problems. Areas with direct sunlight or near moisture sources typically show more movement-related noise issues. Modern construction materials sometimes conflict with older wood - for example, metal fasteners in century-old beams can create distinctive creaks as temperatures change.

Pay special attention to load-bearing joints. These critical connections experience constant stress and often develop characteristic sounds when compromised. Understanding these sound signatures helps differentiate between normal settling and potential structural concerns.

Advanced Lubrication Strategies

Move beyond basic lubricants to specialized solutions. Graphite powder works wonders in hard-to-reach joints, while silicone-based lubricants excel in high-humidity areas. For historical properties, consider natural alternatives like beeswax that preserve antique finishes while reducing friction.

Develop a lubrication schedule based on your home's specific needs. High-traffic areas might need quarterly attention, while other locations may require only annual maintenance. Always clean surfaces before applying new lubricant to prevent gummy buildup.

Structural Repair Techniques

When simple fixes fail, consider these professional approaches: Structural epoxy can stabilize loose joints without visible alterations, while hidden shim systems provide adjustable support for sagging elements. For floor squeaks, specialized screws with breakaway heads allow secure fastening without damaging finished surfaces.

In older homes, sometimes the best solution is controlled movement rather than complete immobilization. Flexible connectors and strategic gaps can accommodate natural wood movement while minimizing noise. This approach respects the building's historical character while improving livability.

When to Call Professional Help

Certain situations demand expert intervention: Persistent noises accompanied by visible cracks or door/window misalignment often indicate serious structural issues requiring professional assessment. Similarly, noises that change character with weather patterns may reveal hidden water damage or foundation problems.

Choose specialists with experience in your home's construction type and era. Historical home experts understand traditional joinery methods, while modern construction specialists know current building science principles. This targeted expertise yields better long-term solutions than generic handyman services.