The role of advanced aerodynamics in reducing vehicle drag

Cutting-Edge Techniques for Minimizing Air Resistance

Perfecting the Lift-Drag Equation

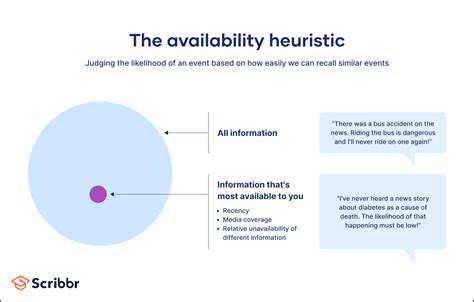

Modern vehicle engineering demands meticulous attention to aerodynamic balance. Through careful manipulation of surface contours and airflow patterns, designers achieve remarkable reductions in air resistance while enhancing upward force. This precise equilibrium stands as the cornerstone of fuel-efficient transportation and extended operational range. Mastering these principles enables the creation of vehicles that combine speed with sustainability.

Critical factors include wing curvature, approach angle, and overall air movement patterns. State-of-the-art digital airflow analysis tools empower engineers to evaluate countless design variations, forecasting performance across diverse operating scenarios.

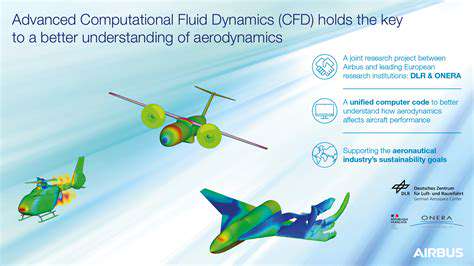

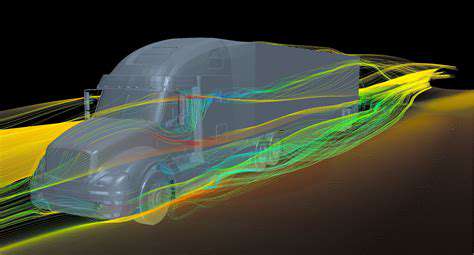

Digital Airflow Simulation Technology

Modern computational analysis provides unprecedented insight into complex air movement patterns surrounding vehicles. These sophisticated models reveal detailed information about speed variations, pressure differentials, and thermal gradients, helping specialists pinpoint resistance hotspots and potential airflow disruptions.

This simulation capability enables exploration of countless design possibilities, dramatically shortening development timelines while yielding superior vehicle efficiency. The power to visualize and measure aerodynamic effects gives engineers the tools to make informed choices, driving continuous improvement in transportation design.

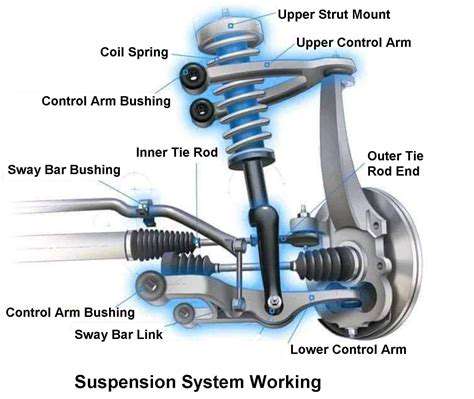

Surface Airflow Regulation

Managing the thin air layer directly contacting vehicle surfaces represents a crucial aspect of aerodynamic refinement. This boundary layer's behavior profoundly influences both resistance and lifting forces. Effective control of this microscopic air region can yield dramatic improvements in overall vehicle efficiency.

Techniques like smooth airflow maintenance, which preserves orderly boundary layer movement, are implemented to decrease resistance. These methods frequently incorporate surface treatments and responsive control mechanisms to establish ideal airflow conditions.

Adaptive Airflow Systems

Responsive airflow control represents a quantum leap in aerodynamic engineering. These intelligent systems employ adjustable components to modify air movement around vehicles, dynamically altering the boundary layer to reduce resistance. Such adaptive solutions provide real-time optimization, automatically adjusting to changing speed and environmental conditions. This flexibility ensures peak performance across the entire operating spectrum.

By actively managing airflow patterns, these systems can prevent undesirable effects like airflow detachment, resulting in substantial resistance reduction and better fuel economy. Implementing these complex systems requires careful engineering to guarantee both reliability and effectiveness.

High-Velocity Aerodynamics

Supersonic aerodynamics addresses the unique challenges posed by vehicles exceeding sound speed. The pressure waves generated at these velocities create significant aerodynamic complications. Specialized approaches become necessary to control these shock waves and lessen their negative impact on resistance and handling.

Innovative design concepts, including precision-edged profiles and carefully contoured wings, help mitigate shock wave effects and maintain stable operation. Developing effective strategies for managing these phenomena remains essential for advancing high-speed transportation.

Next-Generation Wing Architecture

Contemporary vehicles increasingly incorporate sophisticated wing designs optimized for specific performance requirements. These configurations feature complex curves and precisely calculated curvature to maximize lift while minimizing resistance. The continuous evolution of wing technology remains a vital focus for researchers and developers.

Modern wing designs often include specialized features like vertical wingtip extensions, which enhance the lift-to-drag relationship and decrease vortex-induced resistance. These improvements, combined with digital analysis and rigorous testing, contribute significantly to developing high-efficiency vehicles.

Revolutionary Approaches to Air Resistance Reduction

Optimized Contours for Minimal Resistance

Contemporary design philosophy emphasizes form optimization as fundamental to resistance reduction. Progressive shape refinement techniques, surpassing conventional aerodynamic profiles, prove essential for achieving meaningful performance gains. This process involves detailed examination of air movement patterns, employing digital simulation tools to model interactions between vehicle surfaces and surrounding atmosphere.

The evolution of automotive and aircraft surfaces demonstrates this progress. Early designs suffered from high resistance coefficients due to turbulent airflow patterns. Modern contours, crafted with emphasis on smooth airflow and minimized turbulence, show remarkable improvements in resistance reduction. These advancements translate directly to enhanced fuel economy, lower operational expenses, and more sustainable mobility solutions.

Innovative Materials for Enhanced Performance

Material selection significantly impacts resistance reduction efforts. Lightweight yet durable materials help decrease overall mass, directly influencing resistance levels. Additionally, specialized surface treatments can modify the interface between vehicle and air, substantially reducing friction-based resistance. Advanced composite materials, engineered for specific applications, offer exciting possibilities for dramatic resistance improvements.

Emerging nanoscale surface technologies demonstrate particular promise. Engineered microscopic textures can create unique airflow conditions that minimize friction effects. This precision engineering enables noticeable aerodynamic improvements, especially in high-velocity applications where resistance reduction becomes critical. Continued development of these materials remains essential for advancing transportation technology across all sectors.

Dynamic Resistance Control Systems

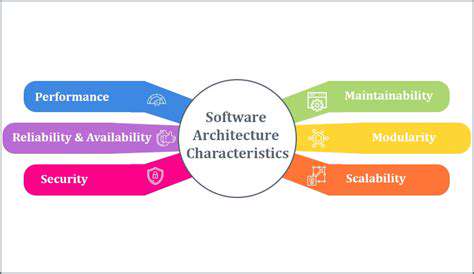

Beyond static design elements, active resistance management systems offer unprecedented optimization potential. These intelligent systems continuously adapt to changing airflow conditions, making real-time adjustments to minimize resistance. Examples include morphing surfaces that respond to airflow variations, or microscopic control elements that manage turbulence patterns.

The potential applications are revolutionary - imagine transportation systems that automatically adjust their profiles based on wind conditions or traffic patterns. While implementation challenges exist, these dynamic approaches promise extraordinary efficiency gains. This adaptive capability allows for optimized performance across diverse operating conditions, representing a significant leap forward in sustainable transportation technology.

Sophisticated digital modeling and control architectures form the foundation for realizing these advanced systems. Integrating these technologies with precision sensors and responsive actuators will create autonomous systems capable of environmental adaptation and continuous performance optimization.

Developing these technologies remains crucial for maximizing efficiency while minimizing ecological impact. The potential for energy conservation and emission reduction makes active resistance management a vital component in sustainable technology development.