Why regular lubrication is critical for automotive bearings

The Unsung Heroes of Movement

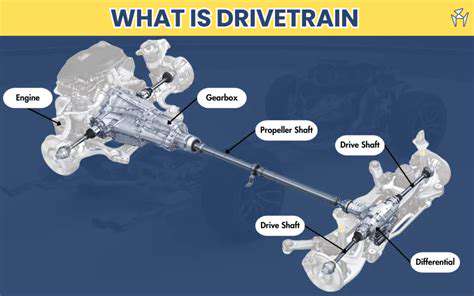

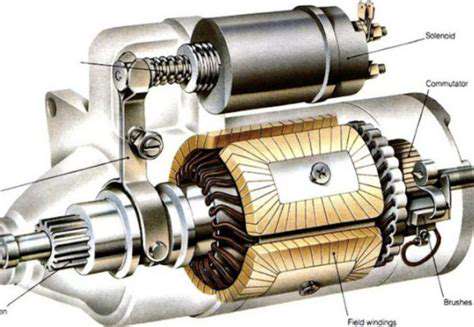

When we think about motion in vehicles, we often focus on the engine or wheels, but there's a hidden network of components working tirelessly behind the scenes - the bearings. These precision-engineered parts enable smooth rotation while supporting massive loads, making them indispensable for every moving part in your car. From the subtle vibrations of your steering wheel to the powerful rotation of your driveshaft, bearings play a crucial role in translating energy into motion.

Automotive bearings, though often overlooked, are truly the unsung heroes that keep our vehicles moving safely and efficiently. They're found in dozens of locations throughout your car, each type specially designed for its specific function and load requirements.

The Diverse Types of Automotive Bearings

Modern vehicles utilize several distinct bearing types, each with unique characteristics. Ball bearings, with their spherical rolling elements, excel in handling radial loads while allowing smooth rotation. Tapered roller bearings combine radial and thrust load capacity, making them ideal for wheel hubs. Plain bearings (bushings) provide simple, low-friction surfaces for oscillating or sliding motions. The choice of bearing type directly impacts vehicle performance, durability, and even fuel efficiency.

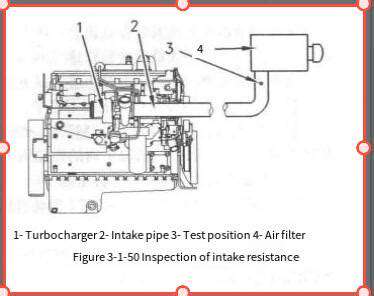

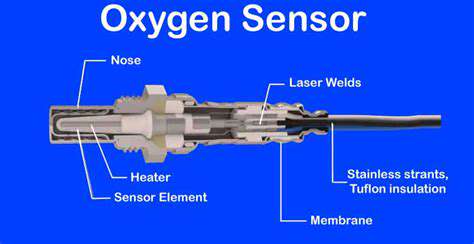

Specialized applications demand specialized bearings. For instance, water pump bearings must withstand constant exposure to coolant while maintaining precise alignment. Transmission bearings face extreme pressure and temperature variations. Understanding these differences is key to proper maintenance and replacement.

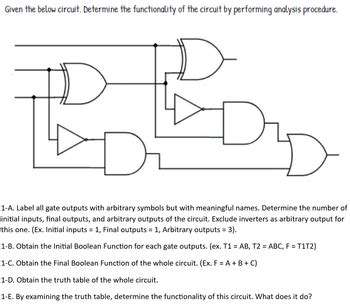

The Anatomy of a Bearing

Examining a typical ball bearing reveals an elegant yet robust design. The inner and outer races provide smooth, hardened surfaces for the balls to roll against. The cage or retainer keeps the balls evenly spaced, while seals protect against contamination. This precise arrangement minimizes friction while maximizing load capacity and service life.

The quality of materials and manufacturing tolerances in bearings can mean the difference between 50,000 miles and 150,000 miles of trouble-free operation. Premium bearings use special steel alloys and heat treatments to resist wear and fatigue.

Bearing Failure: Causes and Consequences

Bearing failures rarely happen suddenly. Early signs include unusual noises (humming, grinding, or growling), vibration, or play in components. Common causes include contamination (dirt or moisture entering the bearing), improper lubrication, excessive loads, or misalignment. Left unchecked, a failing bearing can lead to catastrophic component failure and expensive repairs.

Regular inspection and maintenance are crucial. Many modern bearings are sealed and lubed for life, but others require periodic lubrication. Knowing which type you have and following manufacturer recommendations can prevent premature failure.

Maintaining Bearing Health

Proper bearing maintenance extends far beyond occasional lubrication. It starts with correct installation - many bearings are precision components that require specific tools and techniques. Using the wrong installation method can damage bearings before they even go into service. Regular visual inspections for leaks, damage, or unusual wear patterns can catch problems early.

The condition of your vehicle's bearings directly impacts safety, performance, and repair costs. A failed wheel bearing can lead to loss of control, while a worn transmission bearing can cause gear damage costing thousands to repair.

Advancements in Bearing Technology

Bearing technology continues to evolve. New materials like ceramic hybrids offer reduced weight and increased durability. Advanced sealing technologies better protect against contamination. Some manufacturers are even developing smart bearings with embedded sensors to monitor condition in real time. These innovations promise longer service intervals and improved reliability.

When replacing bearings, consider upgrading to these newer technologies where available. The small additional cost often pays for itself through extended service life and improved performance.

Preventing Friction and Wear: The Lubricant's Role in Bearing Protection

Minimizing Contact Stress

Proper lubrication fundamentally changes how bearing surfaces interact, transforming metal-on-metal contact into a hydrodynamic film that carries the load. This microscopic layer of lubricant prevents direct contact between rolling elements and races, dramatically reducing wear. A well-lubricated bearing can operate for years with minimal wear, while an unlubricated one may fail in hours.

The lubricant's viscosity is critical - too thin and the film breaks down under load; too thick and it creates excessive drag. Temperature also affects viscosity, which is why multi-grade lubricants are essential for automotive applications facing wide temperature ranges.

Optimizing Lubricant Properties

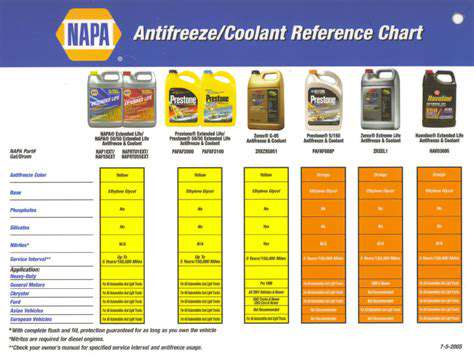

Modern lubricants are complex chemical formulations designed for specific applications. Base oils provide the fundamental lubricating properties, while additives enhance performance. Anti-wear additives form protective layers on metal surfaces, extreme pressure additives prevent welding under heavy loads, and antioxidants slow lubricant breakdown.

The wrong lubricant can be worse than no lubricant at all. Some greases are incompatible with certain bearing materials, while others may not withstand the operating temperatures. Always consult manufacturer specifications when selecting lubricants.

Lubrication Techniques

Different bearing applications require different lubrication methods. Sealed bearings come pre-lubricated and require no maintenance. Open bearings may need periodic greasing through fittings. Some high-speed applications use oil mist or circulating oil systems. The method affects how often lubrication must be replenished and how well contaminants are excluded.

Overgreasing can be as harmful as undergreasing. Excess grease causes churning and heat buildup in rolling bearings. Proper quantity and application technique are essential for optimal performance.

Contamination Control

Dirt and moisture are bearing lubricants' worst enemies. A single grain of sand can create microscopic pits that lead to premature failure. Water contamination causes rust and breaks down lubricants. Effective sealing and proper handling during maintenance are crucial. Cleanliness isn't just desirable - it's absolutely critical for bearing longevity.

When servicing bearings, always work in clean conditions. Use clean tools and fresh lubricants from sealed containers. Even brief exposure to contaminants can significantly reduce bearing life.

Monitoring Lubricant Condition

Lubricants degrade over time due to heat, mechanical shear, and chemical breakdown. Regular inspection can reveal problems before they cause damage. Look for color changes, texture variations, or the presence of metal particles. Some fleets use oil analysis programs to monitor lubricant condition and predict maintenance needs.

Don't assume lubricant is still good just because it's present. Aged lubricant may still look fine while having lost most of its protective properties. Follow manufacturer change intervals religiously.

Beyond the Basics: Choosing the Right Lubricant for Your Vehicle

Understanding Manufacturer Specifications

Vehicle manufacturers spend millions testing lubricants to determine what works best for their components. Their recommendations consider bearing materials, operating temperatures, loads, and expected service life. Using lubricants that meet or exceed these specifications is the single most important factor in bearing longevity.

Don't be fooled by marketing claims - check for actual specification approvals on the lubricant container. API, SAE, and OEM-specific classifications matter more than brand names or price tags.

Synthetic vs. Conventional Lubricants

Synthetic lubricants offer several advantages for bearing applications. They maintain more stable viscosity across temperature extremes, resist thermal breakdown better, and often contain superior additive packages. While more expensive initially, they can extend service intervals and provide better protection in demanding conditions.

For high-performance vehicles or extreme operating conditions, synthetic lubricants are often worth the premium. However, for normal driving with regular maintenance, quality conventional lubricants may suffice.

Specialty Applications

Some vehicle components require specialized lubricants. Wheel bearings often need high-temperature grease. CV joints require special molybdenum-disulfide formulations. Electrical components may need dielectric grease. Using the wrong type can lead to premature failure.

When in doubt, consult your service manual or a trusted mechanic. The small cost of the proper lubricant pales compared to repair bills from using the wrong one.

The Importance of Regular Changes

Even the best lubricants degrade over time. Additives deplete, contaminants accumulate, and the base oil breaks down. Following recommended change intervals is crucial for maintaining protection. Severe service conditions (extreme temperatures, heavy loads, frequent short trips) may require more frequent changes.

Consider your driving habits when determining change intervals. Neglecting lubricant changes is one of the surest ways to shorten bearing life.

Future Trends in Lubrication

Lubricant technology continues to advance. Low-viscosity oils improve fuel efficiency while maintaining protection. Bio-based lubricants offer environmental benefits. Nanotechnology additives promise unprecedented wear protection. Staying informed about these developments can help you make better maintenance decisions.

As vehicles become more sophisticated, so do their lubrication requirements. What worked for your father's car may not be optimal for your modern vehicle.

Optimizing Performance and Fuel Efficiency: The Ripple Effect of Lubrication

The Friction Factor

Friction is the enemy of efficiency, and proper lubrication is its most effective countermeasure. Well-lubricated bearings rotate with minimal resistance, reducing the energy needed to overcome internal friction. This translates directly to improved fuel economy and performance.

Studies show proper lubrication can improve fuel efficiency by 1-2%. While this seems small, over a vehicle's lifetime it amounts to significant savings. In fleet operations, optimized lubrication programs have demonstrated measurable returns on investment.

Temperature Management

Friction generates heat, and heat accelerates wear. Effective lubrication reduces both friction and heat buildup, creating a virtuous cycle of improved efficiency and longevity. Overheated bearings can warp or lose temper, leading to premature failure.

Monitoring operating temperatures can reveal lubrication issues before they cause damage. Infrared thermography is becoming a valuable tool for predictive maintenance programs.

Component Longevity

The cumulative effect of proper lubrication is extended component life. Bearings last longer, seals stay effective, and entire systems operate more reliably. This reduces downtime and repair costs while maintaining optimal performance throughout the service life.

Consider lubrication as an investment rather than an expense. The small additional cost of premium lubricants often pays for itself many times over in reduced maintenance.

System-Wide Benefits

Proper lubrication benefits extend beyond individual components. Well-lubricated drivetrains transmit power more efficiently. Properly maintained wheel bearings reduce rolling resistance. Even accessories like alternators and water pumps last longer with correct lubrication.

A comprehensive lubrication strategy affects nearly every aspect of vehicle performance and operating costs. It's one of the most cost-effective maintenance practices available.

Developing a Lubrication Strategy

Effective lubrication requires planning and documentation. Create a schedule based on manufacturer recommendations and your operating conditions. Use quality products and proper application methods. Keep records to track what was used where and when.

For fleets, consider implementing a lubrication program as part of your preventive maintenance regimen. The discipline pays dividends in reduced breakdowns and lower total cost of ownership.