Exhaust System

Vehicle Maintenance

System Analysis

Performance Evaluation

Acoustic Engineering

Mechanical Design

Resonator Selection

Engineering Design

HTML

Styling

استبدال كاتم الصوت: ضبط عادم السيارة بدقة

دليل خطوة بخطوة ( مبسط )

فهم وظيفة المُرددات

تلعب المُرددات، الموجودة غالبًا في تطبيقات السيارات والصناعات المختلفة، دورًا حاسمًا في تشكيل ترددات الصوت. تم تصميمها لـ

اختيار بديل الرنان المناسب

معايير اختيار الرنان

عند اختيار الرنان,

Read more about استبدال كاتم الصوت: ضبط عادم السيارة بدقة

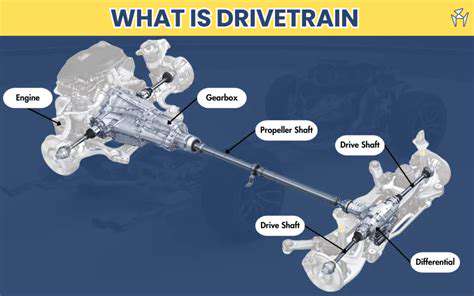

دليل شامل لمكونات نظام الدفع والصيانةوصف التعريف: اكتشف الوظائف الأساسية لمكونات نظام الدفع والمشكلات الشائعة وأفضل الممارسات للصيانة. تعلم كيفية إطالة عمر نظام الدفع في سيارتك وضمان الأداء الأمثل من خلال دليلنا المتعمق.وصف المحتوى: يقدم هذا الدليل لمحة شاملة عن مكونات نظام الدفع، بما في ذلك عمود الكرنك، عمود الكامات، عمود الدفع والوظائف الحرجة لها في تشغيل السيارة. استكشف أهمية الصيانة المنتظمة، والمشكلات الشائعة مثل التآكل الزائد وارتفاع درجة الحرارة، ونصائح عملية لإطالة عمر نظام الدفع الخاص بك. افهم كيف أن الأجزاء عالية الجودة وممارسات التشحيم المناسبة يمكن أن تمنع الإصلاحات المكلفة وتعزز أداء السيارة. ابقَ مُطلعًا على علامات حاجة نظام الدفع لديك إلى الخدمة، مما يضمن تجربة قيادة آمنة وموثوقة.

Jan 28, 2025

دليل أساسي – فهم علامات ارتفاع حرارة السيارة أمر بالغ الأهمية لكل سائق. يوضح هذا الدليل الشامل المؤشرات الرئيسية، والأسباب الشائعة، والإجراءات الوقائية للحفاظ على عمل محرك سيارتك.

Apr 14, 2025

أهمية تحقيق التوازن بين التكلفة والجودة في قطع الغيار

Apr 29, 2025

أفضل الممارسات لصيانة محركات الدفع في السيارات الهجينة الكهربائية

May 03, 2025

تشخيص ومعالجة الضوضاء غير الاعتيادية في أنظمة تكييف الهواء في السيارات

May 14, 2025

أساليب متقدمة لتحليل مشكلات أداء تحمل العجلة

May 20, 2025

خطط صيانة شاملة للسيارات ذات الكيلومترات العالية

May 21, 2025

استكشاف التقنيات المبتكرة في تشخيص السيارات الحديثة

May 21, 2025

توصيات احترافية لحماية دواخل السيارة من التآكل

May 21, 2025