Exhaust System

Vehicle Maintenance

System Analysis

Performance Evaluation

Acoustic Engineering

Mechanical Design

Resonator Selection

Engineering Design

HTML

Styling

マフラーリゾネーター交換:排気系の微調整

段階的なガイド (簡略版)

Read more about マフラーリゾネーター交換:排気系の微調整

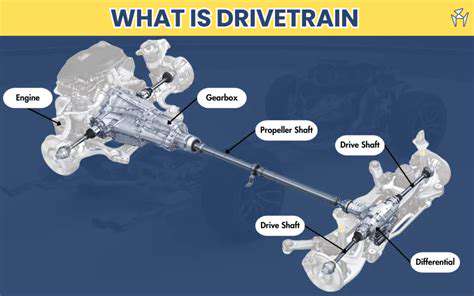

駆動系部品とメンテナンスについての総合ガイドメタディスクリプション:駆動系部品の基本的な機能、一般的な問題、最良のメンテナンス方法を発見してください。私たちの詳細なガイドを通じて、車両の駆動系の寿命を延ばし、最適なパフォーマンスを確保する方法を学びましょう。コンテンツの説明:このガイドでは、クランクシャフト、カムシャフト、ドライブシャフトなどの駆動系部品の詳細な概要を提供します。定期メンテナンスの重要性、過度の摩耗や過熱などの一般的な問題、駆動系の寿命を延ばすための実用的なヒントを探ります。高品質の部品と適切な潤滑の実践が、コストのかかる修理を防ぎ、車両の性能を向上させる方法を理解します。駆動系にサービスが必要なサインを把握し、安全で信頼できる運転体験を確保してください。

Jan 28, 2025

このガイドは、車両オーバーヒートの兆候、一般的な原因、および予防策を詳細に解説し、エンジンの動作を維持します。すべてのドライバーにとって必須のガイドです。

Apr 14, 2025