Exhaust System

Vehicle Maintenance

System Analysis

Performance Evaluation

Acoustic Engineering

Mechanical Design

Resonator Selection

Engineering Design

HTML

Styling

배기 시스템 미세 조정을 위한 레조네이터 교체

단계별 안내 (간소화)

공진기 기능 이해

공진기는 자동차 및 산업 분야에서 흔히 볼 수 있으며, 음파 주파수를 형성하는 데 중요한 역할을 합니다. 그들은

적절한 공진기 교체 선택

공진기 선택 기준

공진기를 선택할 때,

Read more about 배기 시스템 미세 조정을 위한 레조네이터 교체

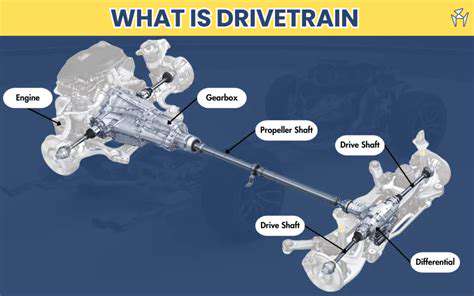

드라이브트레인 부품 및 유지보수에 대한 종합 가이드 메타 설명: 드라이브트레인 부품의 필수 기능, 일반적인 문제 및 유지보수 최선 사례를 알아보세요. 우리의 심층 가이드를 통해 차량 드라이브트레인의 수명을 연장하고 최적의 성능을 보장하는 방법을 배우십시오. 콘텐츠 설명: 이 가이드는 크랭크샤프트, 캠샤프트, 드라이브샤프트 등 드라이브트레인 구성 요소에 대한 철저한 개요를 제공합니다. 정기적인 유지보수의 중요성, 과도한 마모 및 과열과 같은 일반적인 문제, 드라이브트레인의 수명을 연장하기 위한 실용적인 팁을 탐구합니다. 고품질 부품과 적절한 윤활 관행이 비용이 많이 드는 수리를 예방하고 차량 성능을 향상시킬 수 있는 방법을 이해합니다. 안전하고 신뢰할 수 있는 주행 경험을 위해 드라이브트레인이 서비스를 필요로 하는 신호를 항상 확인하세요.

Jan 28, 2025

이 가이드는 차량 과열의 중요한 징후, 일반적인 원인 및 예방 조치를 자세히 설명하여 엔진 작동을 유지합니다. 모든 운전자에게 필수적인 안내서입니다.

Apr 14, 2025