HTML

Styling

Installation

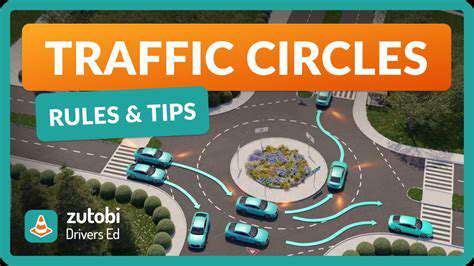

Vehicle

Vehicle Preparation

Mounting Surface

Safety

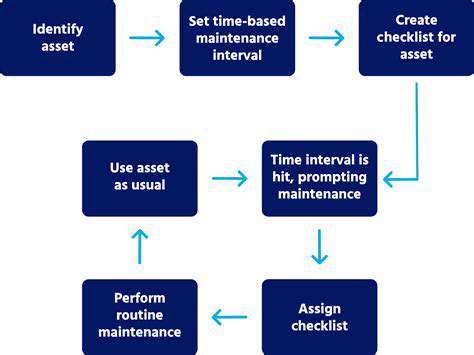

Vehicle_Maintenance

Hartschienen-Installation: Anschnallgurt-Verankerung

Schritt-für-Schritt-Anleitung

Vorbereitung des Fahrzeugs

Bevor Sie mit der Montage Ihrer Trage beginnen, stellen Sie sicher, dass Ihr Fahrzeug ordnungsgemäß vorbereitet ist. Dazu gehört die Sicherung des Bereichs, an dem die Trage befestigt werden soll. Reinigen Sie die Befestigungspunkte gründlich, um eventuelle Verschmutzungen zu entfernen.

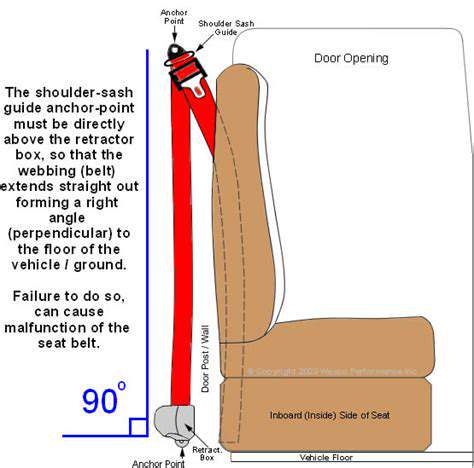

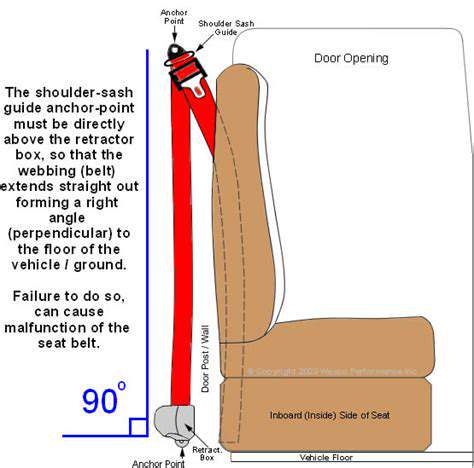

Sicherung der Anschlagpunkte für Sicherheitsgurte

Positionierung der Sicherheitsgurtschlösser

Die korrekte Positionierung der Anschlagpunkte für Sicherheitsgurte ist entscheidend f

Read more about Hartschienen-Installation: Anschnallgurt-Verankerung

Meistern Sie das Aufgabenmanagement mit der Eisenhower-Matrix

Meta-Beschreibung: Erfahren Sie, wie die Eisenhower-Matrix Ihre Produktivität transformieren kann, indem sie Ihnen hilft, Aufgaben basierend auf Dringlichkeit und Wichtigkeit zu priorisieren. Lernen Sie effektive Strategien für das Aufgabenmanagement, die Vorteile der Matrix und wie Sie sie in Ihre tägliche Routine implementieren können, um Effizienz zu steigern und Stress abzubauen. Schlüsselwörter: Eisenhower-Matrix, Aufgabenmanagement, Produktivität, Aufgaben priorisieren, Zeitmanagement, Entscheidungsfindung, Stress abbauen, berufliche Entwicklung, Zielsetzung Inhalt Übersicht: Entfalten Sie das Potenzial des effektiven Zeitmanagements mit der Eisenhower-Matrix! Dieses renommierte Tool hilft Ihnen dabei, Aufgaben in vier Hauptquadranten zu kategorisieren – dringend und wichtig, wichtig aber nicht dringend, dringend aber nicht wichtig, und weder dringend noch wichtig. Wenn Sie verstehen, wie Sie Ihre Aufgaben priorisieren, steigern Sie Ihre Produktivität und minimieren Stress. Entdecken Sie praktische Schritte zur Integration der Matrix in Ihren Alltag, einschließlich klarer Zielvorgaben und Fristen, Nutzung von Zeitblockierungstechniken und kontinuierliche Überprüfung Ihrer Strategien. Sie erhalten auch wertvolle Einblicke in effizientes Entscheiden und persönliche Verantwortung. Ob Sie ein vielbeschäftigter Berufstätiger sind oder einfach nur eine bessere Kontrolle über Ihre persönlichen Aufgaben anstreben, die Eisenhower-Matrix bietet einen systematischen Ansatz zur Erreichung Ihrer Ziele und zur Verbesserung Ihrer Gesamteffizienz. Verabschieden Sie sich vom Gefühl der Überwältigung und begrüßen Sie einen strukturierten Weg zum Erfolg!

Dec 16, 2024

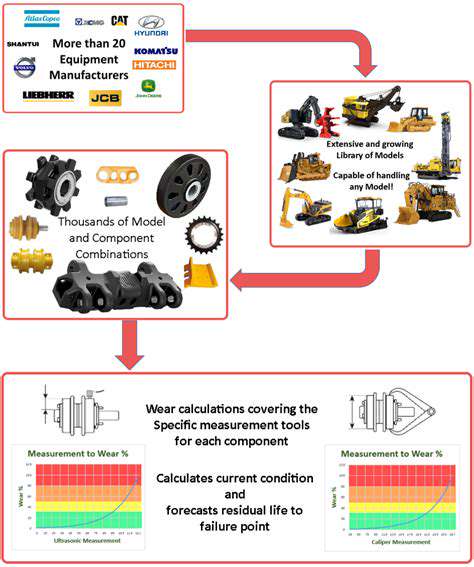

Fortgeschrittene Strategien zur Sicherstellung der Lebensdauer des Fahrgestells

Apr 30, 2025

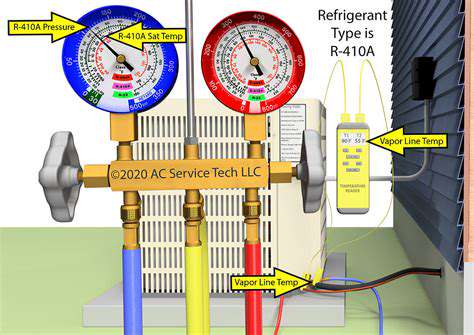

Diagnose und Reparatur häufiger Probleme am Auto-Klimaanlagenkompressor

May 03, 2025

Praktische Lösungen zur Behebung von Quietschen und Geräuschen der Aufhängung

May 06, 2025

Frühe Warnzeichen Haben Sie Probleme mit dem stufenlosen Getriebe (CVT) Ihres Fahrzeugs? Das Erkennen früher Anzeichen von CVT-Getriebeproblemen kann kostspielige Reparaturen vermeiden und Ihr Fahrzeug...

May 06, 2025

Die Vorteile adaptiver Tempomat-Systeme erkunden

May 07, 2025

Detaillierter Leitfaden zur Diagnose und Behebung von Radaufhängungsproblemen

May 08, 2025

Wartungswichtige Punkte für effektive Bremszangen

May 08, 2025

Fortgeschrittene Techniken zur Verbesserung der Fahrzeugleistung bei kaltem Wetter

May 09, 2025

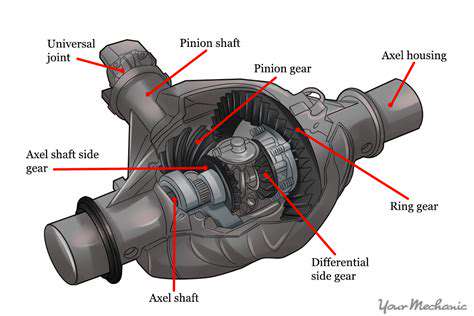

Differenzialölwechsel: Unverzichtbar für AWD/4WD

Jun 09, 2025

Kraftstoffinjektorreinigung: Optimierung der Kraftstoffzufuhr

Jun 09, 2025

Fahrgestellverstärkung: Verbesserung der Handhabung

Jun 27, 2025