HTML

Styling

Installation

Vehicle

Vehicle Preparation

Mounting Surface

Safety

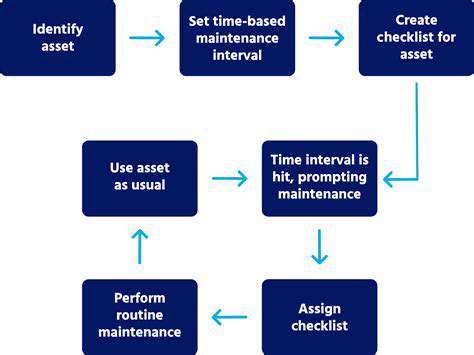

Vehicle_Maintenance

ハーネスバー取付:シートベルトアンカー取付

車両の準備

ハーネスバーの取り付けを開始する前に、車両が適切に準備されていることを確認してください。これには、バーを取り付ける場所を固定することが含まれます。取り付け点を徹底的に清掃して、汚れを取り除いてください。

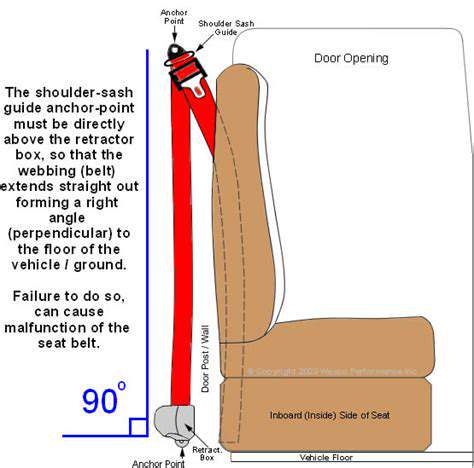

シートベルトアンカーポイントの確保

シートベルトアンカーの配置

Read more about ハーネスバー取付:シートベルトアンカー取付

アイゼンハワー・マトリックスを使用したタスク管理のマスター

メタ説明:アイゼンハワー・マトリックスがいかにして緊急性と重要性に基づいてタスクの優先順位をつけ、生産性を変えるかを発見してください。タスク管理のための効果的な戦略、マトリックスの利点、そしてそれを日常生活に実装して効率を高め、ストレスを軽減する方法を学びます。キーワード:アイゼンハワー・マトリックス、タスク管理、生産性、タスクの優先順位付け、時間管理、意思決定、ストレス軽減、専門能力開発、目標設定 コンテンツ概要:アイゼンハワー・マトリックスで効果的な時間管理の可能性を引き出しましょう!この有名なツールは、タスクを4つの主要な象限に分類するのに役立ちます - 緊急かつ重要、重要だが緊急でない、緊急だが重要でない、そして緊急でも重要でもない。タスクの優先順位を理解することで、生産性を高め、ストレスを最小限に抑えることができます。具体的な目標と締切を設定し、時間ブロッキング技術を活用し、戦略を継続的に見直すなど、マトリックスを日常生活に取り入れるための実践的なステップを探求してください。効率的な意思決定や個人の責任についての貴重な洞察も得られます。忙しいプロフェッショナルであれ、単に個人タスクをより良く管理したい場合であれ、アイゼンハワー・マトリックスは目標を達成し、全体的な効率を向上させるための体系的なアプローチを提供します。圧倒される感覚にさよならを告げ、成功への構造的な道を迎え入れましょう!

Dec 16, 2024

早期警告サイン あなたの車の無段変速機(CVT)に問題が発生していますか?CVTトランスミッションの問題の早期兆候を認識することで、高額な修理を避け、あなたの車を...

May 06, 2025