HTML

Styling

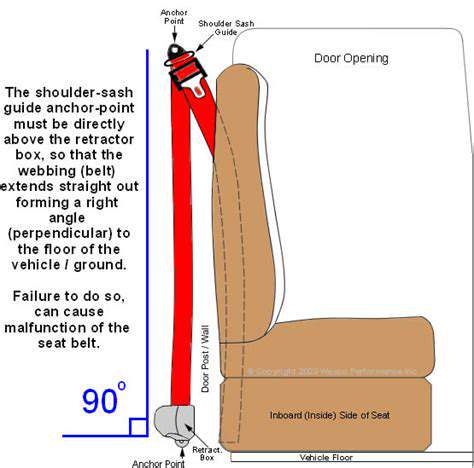

Installation

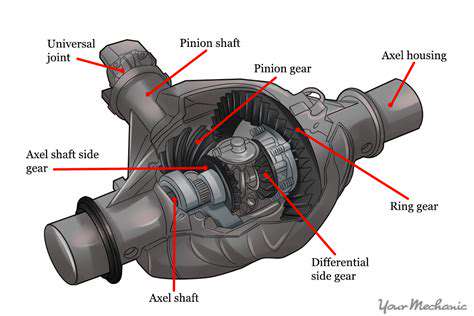

Vehicle

Vehicle Preparation

Mounting Surface

Safety

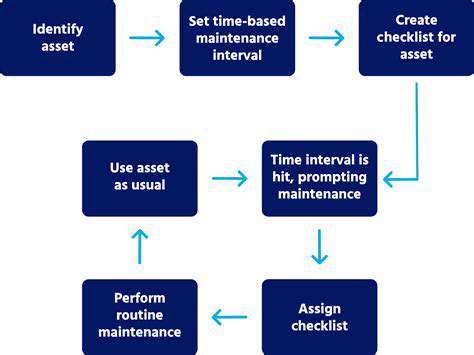

Vehicle_Maintenance

安全带锚点安装:横杆安装

步骤指南

Read more about 安全带锚点安装:横杆安装

用艾森豪威尔矩阵掌握任务管理

元描述:发现艾森豪威尔矩阵如何通过帮助您根据紧迫性和重要性优先考虑任务来改变您的生产力。学习有效的任务管理策略、矩阵的好处,以及如何将其应用于日常生活,以提高效率和减少压力。关键字:艾森豪威尔矩阵、任务管理、生产力、优先考虑任务、时间管理、决策、降低压力、职业发展、目标设定内容概述:利用艾森豪威尔矩阵释放有效时间管理的潜力!这个著名的工具可以帮助您将任务分为四个关键象限——紧急且重要、重要但不紧急、紧急但不重要,以及既不紧急也不重要。通过了解如何优先考虑您的任务,您将提高生产力并减少压力。探索将矩阵融入日常生活的实用步骤,包括设定明确的目标和截止日期、利用时间区块技术以及持续审查您的策略。您还将获得关于高效决策和个人责任的宝贵见解。无论您是忙碌的专业人士,还是只是希望更好地管理自己的个人任务,艾森豪威尔矩阵都提供了一种系统的方法来实现目标,提高整体效率。告别感到不堪重负,迎接通往成功的结构化路径!

Dec 16, 2024