HTML

CSS

Electronic Power Steering (EPS)

Diagnostic Tools

Styling

Réparation de la direction assistée électronique : Direction moderne

Un aperçu

Outils et procédures de diagnostic

Outils essentiels pour le diagnostic du système EPS

Lors de la résolution de pannes du système de direction assistée électrique (EPS), les mécaniciens s'appuient sur des équipements de diagnostic spécialisés. Les garages modernes utilisent généralement des analyseurs avancés qui s'interfacent

Dépannage et maintenance avancés du système EPS

Principes fondamentaux de l'architecture du système EPS

Un dépannage efficace commence par la compréhension des trois architectures EPS de base :

Read more about Réparation de la direction assistée électronique : Direction moderne

Une approche multicouche pour protéger votre maison des éléments. L'anticorrosion extérieure est un aspect crucial de la maintenance de la maison, protégeant votre propriété des effets néfastes de la corrosion. Cette approche multicouche...

Apr 30, 2025

Étapes professionnelles pour la réparation de panneaux de carrosserie automobiles endommagés

May 09, 2025

Meilleures pratiques pour améliorer la durée de vie des chaînes de synchronisation

May 10, 2025

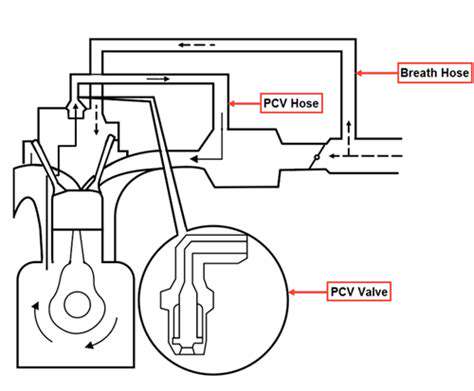

Comprendre le rôle des soupapes PCV dans les moteurs modernes

May 14, 2025

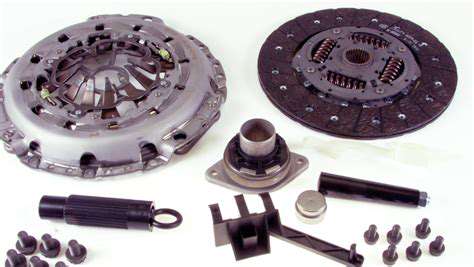

Le rôle des embrayages hautes performances dans la maintenance des voitures de sport

May 15, 2025

Comprendre le rôle des vannes EGR dans les systèmes de contrôle des émissions

May 18, 2025

Causes courantes de surchauffe des transmissions automatiques

May 20, 2025

Explorer les technologies innovantes dans le diagnostic automobile moderne

May 21, 2025

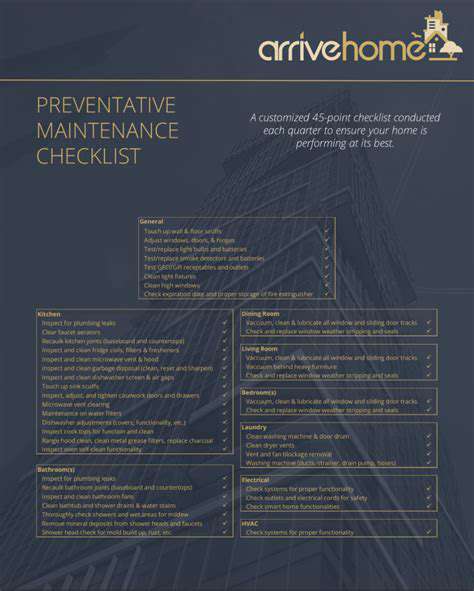

Liste de contrôle de l'entretien essentiel des voitures

Jun 07, 2025

Changement de l'huile de transmission : Prolongement de la durée de vie de la transmission

Jun 10, 2025

Installation de caméra embarquée : Enregistrement de vos trajets

Jun 24, 2025

Polissage et cire de voiture : Faites briller votre voiture

Jun 25, 2025