HTML

CSS

Electronic Power Steering (EPS)

Diagnostic Tools

Styling

전자식 파워 스티어링 수리: 현대식 스티어링

개요

진단 도구 및 절차

EPS 시스템 진단에 필수적인 도구

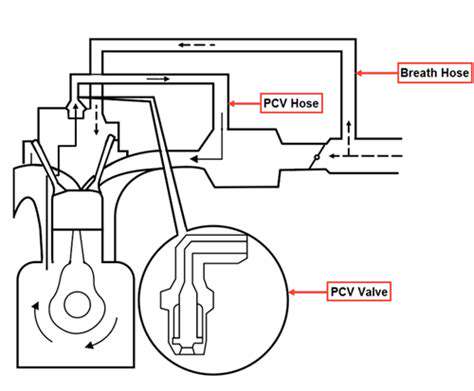

전자식 파워 스티어링 (EPS) 고장을 다룰 때, 정비사는 전문 진단 장비에 의존합니다. 현대의 정비소에서는 일반적으로 고급 스캐너를 사용하여 인터페이스

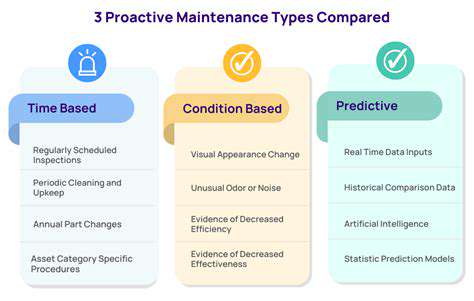

고급 EPS 시스템 문제 해결 및 유지 관리

EPS 시스템 아키텍처 기본 원리

효과적인 문제 해결은 세 가지 핵심 EPS 아키텍처를 이해하는 것으로 시작합니다.

Read more about 전자식 파워 스티어링 수리: 현대식 스티어링

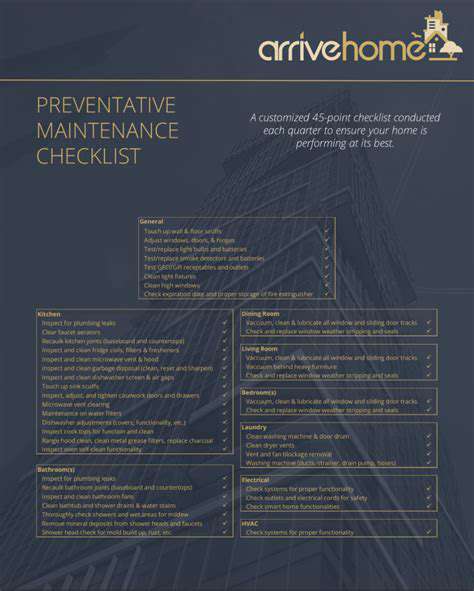

다층 방청 접근 방식으로 주택을 자연 재해로부터 보호합니다. 외장 방청은 주택 유지 관리의 중요한 측면으로, 부식의 해로운 영향으로부터 재산을 보호합니다. 이 다층 접근 방식...

Apr 30, 2025