HTML

CSS

Electronic Power Steering (EPS)

Diagnostic Tools

Styling

電子パワーステアリング修理:現代ステアリング

概要

診断ツールと手順

EPSシステム診断の必須ツール

電動パワーステアリング(EPS)の故障に対処する場合、整備士は専用の診断機器に頼ります。現代のガレージでは、高度なスキャナーを使用して、

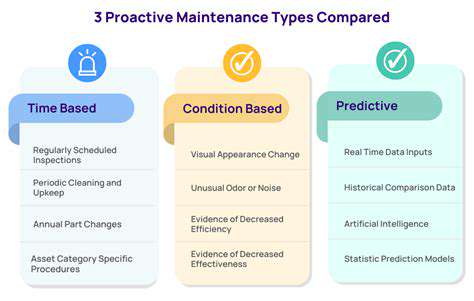

高度なEPSシステムのトラブルシューティングと保守

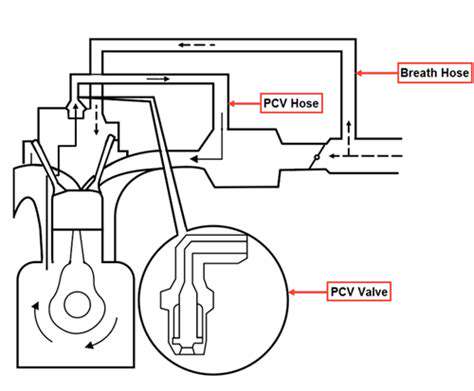

EPSシステムアーキテクチャの基礎

効果的なトラブルシューティングは、3つの主要なEPSアーキテクチャを理解することから始まります。

Read more about 電子パワーステアリング修理:現代ステアリング

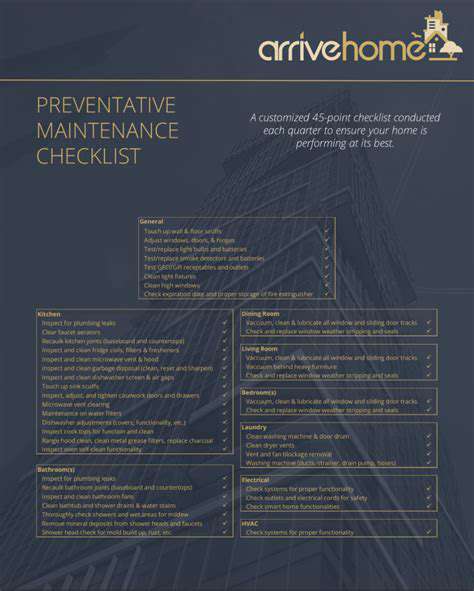

多層防錆アプローチで、家屋を自然災害から保護します。外装防錆は住宅メンテナンスの重要な側面であり、腐食の悪影響から資産を守ります。この多層アプローチ...

Apr 30, 2025