Contents

Floor jacks use hydraulic force to lift vehicles efficiently.

They have lifting capacities typically ranging from 2 to 3 tons.

Different types of floor jacks exist for various lifting needs.

Safety precautions are crucial when using floor jacks.

Choosing the right floor jack depends on vehicle type and weight.

Regular maintenance ensures optimal performance of floor jacks.

Floor jacks provide stability and safety during vehicle repairs.

They are easy to operate, suitable for home mechanics.

Floor jacks are available in many sizes for different vehicles.

They can be a cost-effective tool for vehicle maintenance.

Limited accessibility can be a drawback in tight spaces.

Floor jacks can be heavy and cumbersome to transport.

Proper use and maintenance are essential to avoid safety risks.

Costs of good quality floor jacks can be high.

Bottle jacks utilize a hydraulic mechanism to lift loads.

They are compact, making them portable and easy to store.

Bottle jacks can handle heavier loads than expected.

Safety features in bottle jacks enhance operational stability.

Bottle jacks are generally more affordable than floor jacks.

They serve a variety of applications beyond automotive use.

Limited lifting capacities can restrict heavy lifting tasks.

Bottle jacks may be unstable on uneven surfaces.

They often have height limitations for larger applications.

Operational complexity can hinder inexperienced users.

High-quality bottle jacks can be quite expensive.

What is a Floor Jack?

Understanding the Mechanism of a Floor Jack

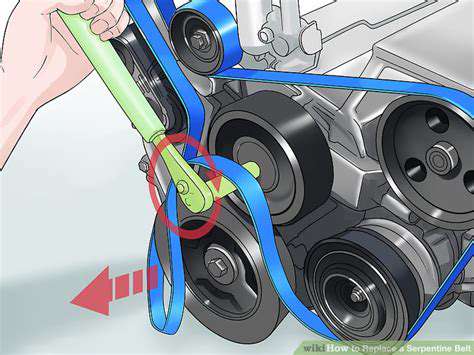

A Floor Jack Operates using hydraulic force to lift vehicles safely and efficiently. The hydraulic system consists of a pump, piston, and various seals that work together to generate the lifting power necessary for supporting heavy loads. Typically, when the handle is pumped, hydraulic oil is forced through a valve, moving the piston and lifting the jack. This process allows for controlled lifting, which is essential when responding to different vehicle weights and designs.

Most floor jacks have a rated Lifting capacity ranging from 2 tons to 3 tons, with some specialized models able to lift even heavier loads. A standard home garage floor jack is usually rated for 2 tons, which is sufficient for most passenger vehicles and light trucks. It's crucial to check the jack's specifications against the weight of the vehicle you'll be lifting to ensure safety and effectiveness.

Types of Floor Jacks

There are various types of floor jacks available, with each designed to meet specific lifting requirements and environments. The most common type is the hydraulic floor jack, known for its efficiency and ease of use. However, other types include aluminum floor jacks, which offer a lightweight alternative, and heavy-duty floor jacks, built to handle heavier vehicles and tougher conditions. Each type has its unique advantages and is engineered for specific tasks in automotive repair or maintenance.

Interestingly, jack types can also vary in the way they raise vehicles. Some use a single-action mechanism, while others may have a double-action feature that allows for faster lifting. As an automotive enthusiast, exploring various types can help you make an informed decision based on your particular needs.

Safety Precautions When Using a Floor Jack

Using a floor jack involves inherent risks, and taking safety precautions is paramount. Always ensure that the vehicle is on a flat, stable surface before attempting to lift it. Using wheel chocks can prevent the vehicle from rolling, which adds an important layer of security during the lifting process. Another critical step is to never place any part of your body beneath a raised vehicle without using jack stands to support the car securely.

Choosing the Right Floor Jack for Your Needs

Selecting the appropriate floor jack involves considering the types of vehicles you plan to lift and the environments in which you will operate. This consideration often boils down to weight capacity, lifting height, and portability. For general home use, a standard hydraulic floor jack with a capacity of 2 tons is likely sufficient to accommodate most passenger cars.

However, if you foresee using it for larger trucks or SUVs, consider investing in a higher-capacity model. Additionally, if storage space is a concern, opt for a lightweight aluminum jack that can be easily maneuvered and stored. Always read reviews and check ratings to find a reliable model that meets safety standards and user satisfaction.

Maintenance Tips for Floor Jacks

To ensure your floor jack remains in optimal working condition, regular maintenance is essential. Start with a routine check of the oil levels in the hydraulic system; low oil can lead to decreased performance and potential failure. Replacing hydraulic fluid as needed and checking for any leaks or damaged seals will prolong the jack's lifespan significantly.

Another important aspect of maintenance is ensuring all moving parts are lubricated. Dust and debris can accumulate over time, potentially causing the jack to operate less efficiently. Cleaning the jack after each use and following the manufacturer’s instructions for maintenance will help keep your floor jack functional for years to come.

Advantages of Using a Floor Jack

Enhanced Stability and Safety

Using a floor jack provides a far more stable lifting platform compared to many other types of jacks. This stability is essential when you're working on vehicles, as it significantly reduces the risk of the car slipping or falling while you’re underneath it. The broader base of floor jacks is designed to evenly distribute weight, which is crucial for safety while performing repairs or maintenance tasks.

Many floor jacks come equipped with safety features, such as the built-in safety lock mechanism, that adds an extra layer of assurance. Even if you’re a seasoned mechanic, it's vital to recognize that these features aren’t merely add-ons; they are essential tools that ensure the safety of both the vehicle and the mechanic. Research shows that over 2,600 injuries occur yearly in the U.S. due to falling vehicles, emphasizing how crucial it is to have a reliable lifting mechanism.

Ease of Use and Convenience

One of the standout features of a floor jack is its ease of operation. Unlike some more intricate lifting devices that require extensive setup or complicated maneuvers, floor jacks are designed for straightforward use. This is particularly advantageous for home mechanics who may not have the extensive training that professional mechanics possess. Most models can lift a vehicle within seconds, allowing you to get your work done efficiently.

Moreover, many floor jacks come with features like quick lifts, enabling you to raise the car to the desired height with minimal effort. This user-friendly design means that whether you’re checking your oil or replacing brake pads, you can do so without excessive strain. Investing in a good floor jack is not just about lifting; it significantly enhances the overall convenience of maintaining your vehicle.

Variety and Versatility

Floor jacks come in a wide range of sizes and lifting capacities, making them suitable for various vehicles, from compact cars to heavy trucks. This versatility means that you don’t have to purchase multiple jacks for different tasks, which can be a cost-effective solution for both professionals and hobbyists. Additionally, some floor jacks offer adjustable height settings, allowing for flexibility based on the specific requirements of a job.

Furthermore, certain models are designed with unique features such as low-profile capabilities, making them a favorite for low-riding cars. This adaptability allows you to choose a floor jack that best fits your specific needs, such as portability or weight capacity, ensuring that you are always well-equipped to handle any automotive situation.

Cost-Effectiveness in the Long Run

Investing in a floor jack can be a financially smart choice over time. While the initial cost might be higher than a basic jack, the durability and versatility offered by floor jacks generally translate to fewer replacements and repairs in the long run. A high-quality floor jack can last for years, providing reliable performance whenever needed. This means you won’t have to routinely spend more on repairs or replacements, which adds up over time.

Moreover, you can perform maintenance tasks yourself, saving on labor costs associated with professional services. It’s worth noting that simple tasks like oil changes or tire rotations can be performed at home, enhancing your knowledge of vehicle maintenance while also saving you money. Therefore, purchasing a floor jack not only improves your vehicle's upkeep routine but also offers significant financial benefits.

Disadvantages of Floor Jacks

Limited Accessibility in Tight Spaces

One of the most significant drawbacks of using floor jacks is their size. These jacks require ample clearance not only for operation but also for positioning under vehicles. In tight garages or under low-profile cars, even a slight limitation in maneuverability can lead to ineffective use of the jack.

A floor jack typically measures at least 3 to 4 inches in height. For cars with limited ground clearance, this can pose a problem. If the car is too low, you might find yourself unable to slide the jack underneath without additional tools or modifications.

Weight and Portability Issues

While floor jacks are renowned for their stability and lifting power, their weight can be cumbersome. On average, a standard floor jack weighs between 50 to 100 pounds. This often makes them Less Portable Compared to lighter alternatives like bottle jacks. If you're working at various locations, lugging a heavy floor jack can become tiring quickly.

In addition, manual handling of such weight carries the risk of injury. Transporting a cumbersome jack can be a nuisance, and it's crucial to consider whether a more portable option might better suit your needs, especially if on-the-go tasks are frequent.

Potential for Safety Risks

Floor jacks, if not used properly, present safety hazards that users must be aware of. Regular maintenance is essential; any rust, oil leaks, or mechanical faults can compromise stability. These issues can lead to catastrophic failures while lifting a vehicle, resulting in property damage or personal injury.

Moreover, the need for jack stands is paramount. Relying solely on a floor jack without securing the vehicle can lead to grave accidents. Always ensure that your workspace is free of hazards and that you follow safety protocols diligently when operating a floor jack.

Cost Considerations

When choosing a floor jack, the cost can become a drawback, particularly for hobbyists or occasional users. Good quality floor jacks range from $150 to upwards of $600. This investment often excludes additional expenses such as maintenance, repairs, or the purchase of supplementary tools like jack stands.

While the upfront cost of a high-quality floor jack may seem justified, it's important to evaluate how frequently you'll use it. If your needs are intermittent, consider whether a less expensive or a different type of jack might be a smarter choice, potentially saving you money in the long run.

What is a Bottle Jack?

Understanding the Mechanics of a Bottle Jack

At its core, a bottle jack operates on a simple Hydraulic mechanism. It utilizes hydraulic fluid to create pressure, allowing it to lift heavy loads easily. The design consists of a base, a cylinder, and a piston. This mechanism enables the jack to convert force applied at one point into a much larger force at another, facilitating the lifting process.

The hydraulic system is highly efficient, capable of raising substantial weight with minimal effort from the user. Typically, common models can lift weights ranging from 2 to 20 tons, making them suitable for various automotive repairs and maintenance tasks.

Applications of Bottle Jacks

Bottle jacks find their utility in various automotive applications. They are particularly favored for servicing large vehicles like trucks, SUVs, and buses due to their lifting capacity and stability. Additionally, they are frequently used in construction projects, where heavy machinery or materials need to be precisely positioned.

- Automotive repairs

- Construction projects

- Heavy equipment maintenance

Home mechanics also appreciate the compact design, allowing easy storage without sacrificing lifting power. Whether you're replacing a tire or lifting machinery, a bottle jack can be an invaluable tool.

Safety Precautions When Using a Bottle Jack

While bottle jacks are generally safe when used correctly, certain precautions are essential to ensure user safety. Always use the jack on a stable, level surface to prevent tipping. It's also critical to never exceed the manufacturer’s weight limit.

Wearing safety gear, including gloves and goggles, is important to mitigate risks during operations. Additionally, working with a jack stand is recommended to support the load once lifted, preventing accidents caused by jack failure.

Choosing the Right Bottle Jack

Selecting the right bottle jack involves considering various factors, such as the weight of the vehicle or equipment you'll lift and the maximum lifting height required. It's imperative to choose a jack that matches or exceeds your lifting needs.

Features like material durability, piston stroke length, and overall design should also be weighed in the decision. Models made from high-grade steel typically offer better stability and support over time, reducing the likelihood of malfunctions.

Maintenance Tips for Bottle Jacks

Proper maintenance is key to ensuring the longevity and performance of a bottle jack. Regularly inspect the jack for oil leaks and ensure the hydraulic fluid is at the appropriate level. Routine checks can prevent unexpected failures during critical moments.

Storing the jack in a dry environment is also recommended to avoid rusting and degradation of parts. By adhering to these simple maintenance steps, one can ensure that their bottle jack remains functional for years to come.

Advantages of Using a Bottle Jack

1. Compact Design and Portability

Bottle jacks are known for their compact design, making them a convenient option for those with limited storage space in their vehicle or garage. Unlike floor jacks, which can be large and cumbersome, bottle jacks fit snugly in tight spaces. Their vertical shape allows easy placement in the trunk of a car or under a seat without taking up too much room.

Portability is a key advantage, especially for roadside emergencies. Weight-wise, most bottle jacks range from 2 to 8 tons, so they're manageable for most individuals. Having a lightweight but effective jack on hand can give drivers peace of mind, knowing they can address minor vehicle issues without reliance on external help.

2. Increased Lifting Capacity

One of the standout features of bottle jacks is their lifting capacity. These jacks are designed to handle heavier loads than one might expect due to their unique hydraulic mechanism. Typically, you can find bottle jacks rated between 2 tons and 50 tons, catering to various needs, from changing a tire to lifting heavy machinery. This range makes them exceptionally versatile tools.

For instance, commercial and industrial sectors frequently utilize high-capacity bottle jacks when working with heavy equipment. On construction sites, they are often used to lift heavy materials into position safely. Their strong lifting power allows workers to complete tasks more efficiently and with a reduced risk of injury.

3. Stability and Safety Features

Safety is paramount when using any lifting equipment, and bottle jacks incorporate several features that promote stability during operation. Most models come with a broad base, ensuring that they remain firmly planted even under significant weight. This design minimizes the risk of tipping or collapsing, which can lead to serious accidents.

Additionally, many bottle jacks include built-in safety valves. These valves prevent overloading, which can be particularly beneficial when lifting heavy vehicles. Such precautions assure users that they are operating safely, adding to the overall appeal of using a bottle jack for various lifting tasks.

4. Cost-Effectiveness

When shopping for lifting equipment, budget considerations often come into play. Bottle jacks usually come at a lower price point compared to floor jacks, making them an attractive option for DIY enthusiasts and professional mechanics alike. This affordability does not come at the cost of quality, as many bottle jacks are built with durable materials and components, providing excellent longevity and reliability.

In a recent analysis, many users reported that investing in a bottle jack significantly reduced their long-term vehicle maintenance costs, as it allows them to perform repairs and tire changes independently. Thus, for individuals looking to save money on car repairs, a reliable and affordable bottle jack can be a smart investment.

5. Versatility for Various Applications

Bottle jacks showcase exceptional versatility, making them suitable for myriad applications beyond just vehicles. They can lift equipment in workshops, serve in industrial settings, or assist in construction projects. Many enthusiasts appreciate their utility in automotive work, while others use them for home lifting tasks, such as raising furniture during renovations.

The adaptability of bottle jacks is evident as they can perform a range of tasks, from changing tire sizes on vehicles to lifting heavy appliances during home improvement projects. For hobbyists or professionals with diverse lifting needs, a bottle jack stands out as a multi-functional tool that can save time and effort in various scenarios.

Disadvantages of Bottle Jacks

Limited Lifting Capacity

Bottle jacks are designed for specific lifting capacities, typically ranging from 2 to 50 tons. This limitation can be a drawback when dealing with heavier vehicles or equipment. For example, a standard bottle jack rated for 12 tons may not suffice for larger trucks or machinery, requiring users to seek alternatives that can handle increased loads safely.

Moreover, the limited range necessitates careful selection and awareness of the jack's specifications during use. A miscalculation in lifting requirements can lead to safety risks or equipment damage, highlighting the importance of understanding the limits that bottle jacks impose. Consequently, users should always verify their lifting needs before relying on this equipment.

Stability Concerns

One significant disadvantage of bottle jacks is their potential instability. Unlike floor jacks that have wider bases for better stability, bottle jacks can tip over if not positioned correctly, especially on uneven surfaces. This poses a serious safety risk when working under vehicles.

Additionally, this means that users need to exercise extreme caution when using bottle jacks, ensuring they are on solid, flat ground. A tip-over can result not only in personal injury but also in damage to the vehicle or jack itself, emphasizing the need for careful setup and operation to mitigate risks associated with stability.

Height Limitations

While bottle jacks excel at lifting vehicles high enough for tire changes or maintenance tasks, they have Height Limitations that can be restrictive. For many bottle jacks, the maximum lift height is often about 18-20 inches, which may not be enough for larger lifting applications. Thus, users might find themselves struggling if trying to work on taller vehicles or heavy equipment that requires additional clearance.

This height concern means that users must take into account the type of work they plan to undertake. For those who frequently service larger vehicles, it might be worth considering a different jack type that offers better vertical lifting capabilities, ensuring both efficiency and safety.

In practice, this often leads technicians to alternate between different types of jacks, a scenario that could weaken workflow efficiency and complicate tasks if not managed properly.

Operational Complexity

Using bottle jacks can sometimes be less straightforward compared to other jacks. Each bottle jack operates via a hydraulic mechanism that requires precise pumping to achieve the desired lift. For inexperienced users, understanding the operation of the screw mechanism and hydraulic leverage can take time.

This operational complexity can be a barrier for those who might require a quick lift without extensive training or practice. For a smoother user experience, those opting for bottle jacks should familiarize themselves with the device's mechanics and maintenance protocols to ensure proper function and safety during use.

Higher Cost of Quality Models

While bottle jacks are often perceived as budget-friendly, high-quality models that offer reliable performance can be quite an investment. Users may find that the lower-end options lack durability or safety features, leading them to consider more expensive brands that guarantee better reliability and longevity.

Investing in a quality bottle jack means users are also considering aspects like safety features, construction materials, and weight capacity, which can all drive up the cost significantly. Eventually, users should weigh the overall benefits against the initial financial outlay and evaluate how often they will use such a tool before committing to a purchase, ensuring value in their investment.