Advanced maintenance strategies for turbocharged engines

Operators should establish baseline measurements for oil pressure, operating temperatures, and exhaust readings. Documenting these benchmarks creates reference points for identifying abnormal conditions. Modern engines often include dashboard indicators, but savvy technicians supplement these with manual checks using specialized gauges. This dual verification approach catches discrepancies that automated systems might miss.

Regular Oil Changes and Filter Replacements

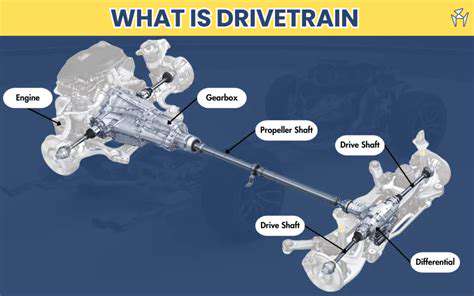

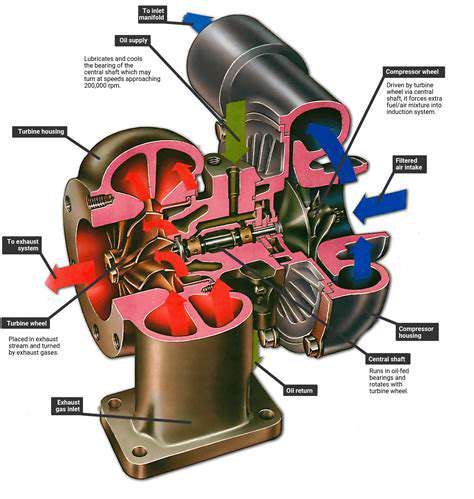

Lubrication systems require more frequent attention in turbocharged applications. While manufacturers suggest service intervals, real-world conditions often necessitate 25-30% more frequent changes. Contaminants in used oil act like microscopic sandpaper, accelerating wear on precision bearings and shafts. High-performance synthetic formulations specifically designed for forced induction systems provide superior film strength under extreme pressures.

Oil filters deserve equal consideration. Premium multi-layer filters capture smaller particles than standard versions, preserving bearing surfaces. Technicians should note any metal flakes in used filters - their presence signals impending component failure. Some operations implement oil analysis programs, sending samples to labs for detailed contamination reports.

Monitoring Exhaust Gas Temperatures (EGTs)

Exhaust systems tell a turbocharger's health story. Persistent readings above 850°C (1562°F) indicate serious trouble that demands immediate attention. Common causes include restricted exhaust flow, incorrect fuel mixtures, or turbine damage. Portable infrared thermometers allow quick spot checks at various points in the exhaust stream, revealing hot spots that suggest flow restrictions.

Modern engine control units often include EGT monitoring, but adding auxiliary sensors provides redundancy. Data loggers can track temperature trends over time, helping identify gradual deterioration before catastrophic failure occurs. This approach proves particularly valuable for engines operating in variable load conditions.

Inspecting for Leaks and Wear

Weekly visual inspections should become standard practice. Look for telltale oil streaks around housings or coolant residue near water-cooled bearing sections. Even minor leaks warrant investigation - under boost pressure, small seepages rapidly become major losses. Pay special attention to shaft play by gently attempting to wiggle the compressor wheel (with the engine off). More than 1mm of movement typically indicates bearing wear.

Vibration analysis tools can detect early-stage imbalances before they become visible. Technicians should establish baseline vibration signatures when components are new, then compare periodic readings to identify developing issues.

Cleaning Intercooler and Air Intake Systems

Restricted airflow forces turbochargers to work harder, reducing efficiency and lifespan. Monthly intercooler inspections prevent performance-robbing buildup of oil residue and road debris. Pressure testing reveals internal blockages that visual inspections might miss. For severe contamination, specialized cleaning solutions restore optimal heat transfer.

Intake systems require equal attention. Aftermarket high-flow filters often sacrifice filtration quality - stick with OEM-specification media for best protection. Check all clamps and connections for tightness; even small leaks allow abrasive particles to bypass filtration.

Implementing a Comprehensive Maintenance Schedule

Successful programs combine manufacturer guidelines with operational realities. Create a color-coded calendar distinguishing between daily checks, weekly tasks, and major service intervals. Include space for technician notes about unusual observations. Digital maintenance systems can automate reminders and track component histories, but paper logs work equally well for smaller operations.

Consider creating a turbo health index scoring system based on key measurements. This quantifiable approach helps justify maintenance expenditures to management by demonstrating return on investment through extended component life.

Understanding Turbocharger Diagnostics

Unusual sounds provide early failure warnings. High-pitched whines often indicate bearing issues, while whooshing noises suggest boost leaks. Keep a digital recorder handy to document sounds for comparison over time. Performance tracking provides another diagnostic tool - establish acceleration benchmarks when the system is new, then monitor for gradual changes.

Invest in a quality boost pressure gauge. Fluctuations or failure to reach target pressures reveal problems ranging from wastegate malfunctions to compressor inefficiencies. Combine pressure readings with airflow measurements for complete system assessment.

Implementing Predictive Maintenance Techniques

Predictive Maintenance Models

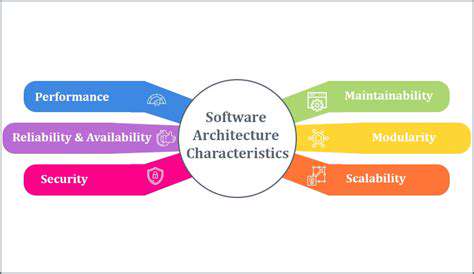

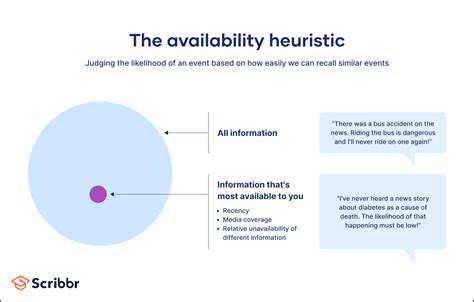

Modern failure prediction systems combine sensor networks with analytical software, creating maintenance alerts before problems become visible. The most effective models incorporate three data streams: real-time sensor inputs, historical performance records, and comparable fleet data. Vibration analysis systems have evolved beyond simple amplitude measurements - modern units track frequency patterns that reveal specific failure modes.

Selecting appropriate algorithms depends on failure characteristics. Slow-developing issues like bearing wear suit time-series analysis, while sudden failures require pattern recognition models. Cloud-based systems now offer affordable predictive capabilities for small operations through subscription services.

Data Collection and Analysis for PdM

Strategic sensor placement maximizes data quality. Temperature probes should contact metal surfaces directly rather than measuring air temperatures near components. Vibration sensors require rigid mounting to avoid false readings. Wireless systems simplify retrofitting existing equipment, but verify signal reliability in electrically noisy environments.

Data cleaning proves equally important as collection. Develop protocols for identifying and compensating for sensor drift. Time-synchronization across all measurement points ensures accurate correlation of events. Many operations benefit from hiring dedicated data technicians to maintain information quality.

Implementing PdM in a Practical Setting

Successful implementation requires cultural adaptation. Technicians often resist replacing experience with algorithms - address this by demonstrating how predictive tools complement rather than replace human expertise. Start with non-critical systems to build confidence in the approach. Create simple visual dashboards that highlight actionable information without overwhelming users with data.

Measure success through specific metrics like false alarm rate and mean time between failures. Refine models quarterly based on operational experience. Consider third-party audits to validate system effectiveness and identify improvement opportunities.

Engine Monitoring and Data Analysis for Optimized Performance

Engine Performance Metrics

Comprehensive monitoring requires looking beyond basic parameters. Transient response times during acceleration reveal turbocharger health more accurately than steady-state measurements. Fuel trim percentages indicate combustion efficiency - consistent negative corrections suggest airflow restrictions. Exhaust gas recirculation (EGR) rates affect turbo performance and require monitoring in modern emissions-controlled engines.

Establish performance envelopes rather than single target values. For example, normal oil pressure might range between 40-65 psi depending on temperature and RPM. Documenting these ranges accounts for normal operational variations.

Data Acquisition and Logging

Sample rates must match system dynamics. Turbocharger-related measurements require at least 10Hz sampling to capture meaningful transient data. Ensure data loggers have sufficient memory capacity for extended recording periods during troubleshooting. Many modern systems support conditional triggering - recording only when parameters exceed set thresholds to conserve storage space.

Metadata proves equally valuable as numerical data. Always record ambient conditions, fuel quality, and load factors that might affect measurements. This contextual information becomes crucial during later analysis.

Data Visualization and Reporting

Effective dashboards use layered information presentation. Primary displays should highlight only critical alarms, with drill-down capabilities for detailed analysis. Trend lines work better than single-point indicators for most parameters. Color-coding normal, warning, and danger ranges improves quick interpretation.

Automated report generation saves countless hours. Configure systems to produce weekly health summaries and exception reports highlighting parameters approaching limits. Include graphical representations of trends over relevant time periods.

Beyond the Basics: Specialized Maintenance Procedures for Specific Turbocharged Engine Applications

Specialized Maintenance for High-Performance Turbocharged Engines

Competition engines demand extraordinary measures. Post-race teardowns become mandatory, with micrometer measurements of all critical clearances. Ceramic coatings on turbine housings reduce heat soak between events. Special attention goes to wastegate mechanisms - high boost pressures accelerate wear on these components. Many teams implement pre-race checklists covering dozens of specific measurements.

Oil systems often receive upgrades including auxiliary coolers and high-capacity pumps. These modifications require corresponding maintenance adjustments - for example, increased oil volume means longer warm-up periods before hard use. Document all modifications and their maintenance implications in detail.

Precision Tuning and Diagnostics for Turbocharged Systems

Professional-grade diagnostic tools reveal subtleties consumer scanners miss. Pressure transducers installed at multiple points in the intake and exhaust systems map flow characteristics. Smoke machines help locate minute boost leaks that evade other detection methods. Oscilloscopes monitor injector and ignition signals for timing anomalies that affect turbo efficiency.

Create tuning logs documenting all adjustments and their effects. This historical record helps diagnose later issues and refine setups. Many tuners videotape dyno sessions to correlate visual observations with data traces.

Addressing Unique Challenges of Turbocharged Engine Components

Heat management becomes paramount in performance applications. Thermal imaging cameras identify hot spots needing additional shielding or cooling. Exhaust manifold studs require periodic torque checks - thermal cycling causes gradual loosening. Upgraded fasteners with special coatings often prove worthwhile investments.

Water-cooled turbochargers introduce additional maintenance considerations. Coolant quality must meet exacting standards to prevent deposit buildup in narrow cooling passages. Some operations install inline filters in coolant feed lines to catch debris before it reaches critical components.