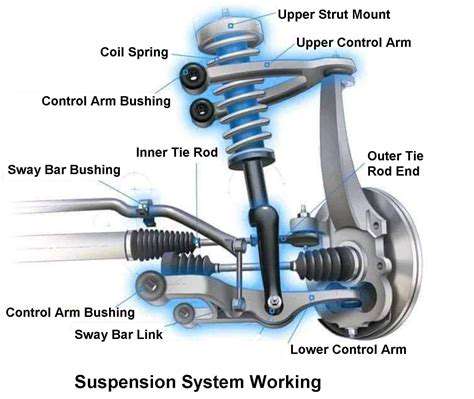

Importance of regular inspections for steering system components

Beyond the Basics: Advanced Inspection Techniques

Advanced Visual Inspection Techniques

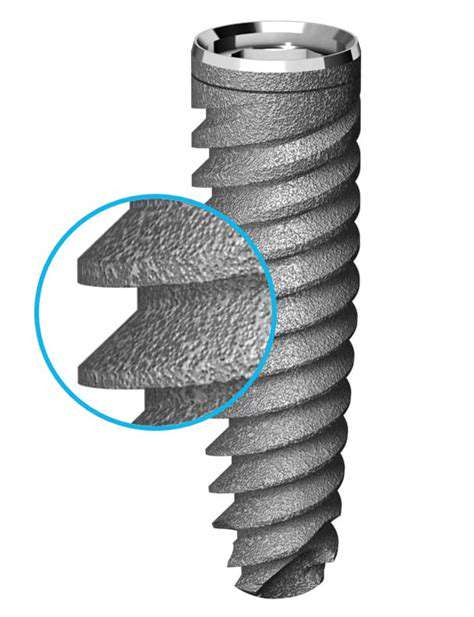

While basic visual checks are essential, modern inspection demands more sophisticated approaches. Specialized tools like magnifying glasses, borescopes, and thermal imaging cameras reveal hidden wear patterns, corrosion, or structural damage that naked eyes might miss. However, these tools require trained professionals who understand how to interpret subtle signs accurately. Certification programs ensure inspectors develop the necessary skills to assess component conditions thoroughly.

Creating a customized checklist for each equipment type transforms inspections from haphazard to systematic. A well-designed checklist specifies exact inspection points, defines acceptable condition thresholds, and matches tools to each task. This methodology not only guarantees comprehensive coverage but also establishes consistent standards across multiple inspections, significantly reducing oversight risks.

Employing Non-Destructive Testing (NDT) Methods

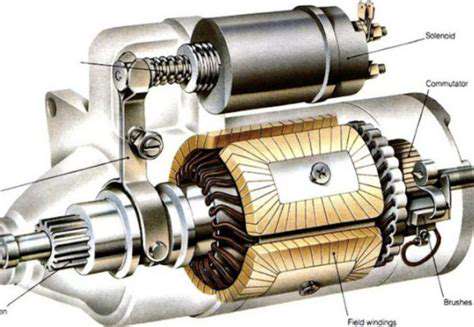

NDT revolutionizes how we evaluate material integrity without compromising functionality. Techniques like ultrasonic testing penetrate materials to identify subsurface flaws, while radiographic testing works like medical X-rays for industrial components. Magnetic particle inspection excels at finding surface cracks in ferromagnetic materials. These methods prove indispensable for safety-critical applications where internal defects could lead to disastrous consequences.

Selecting the appropriate NDT technique involves careful consideration of material properties and potential failure modes. Misapplication of methods or misinterpretation of results can create dangerous false assurances. Proper training in multiple NDT methodologies allows inspectors to choose the optimal approach for each unique situation.

Implementing Predictive Maintenance Strategies

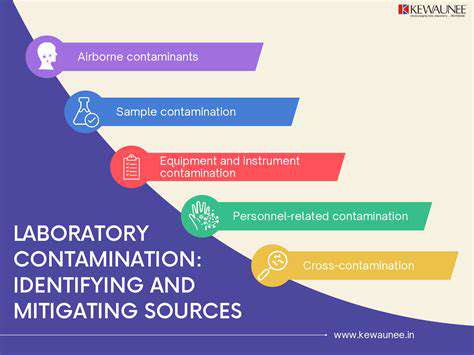

Modern maintenance philosophy shifts from reactive repairs to failure prevention through data analysis. Continuous monitoring of vibration signatures, thermal patterns, and pressure fluctuations creates an early warning system for mechanical components. Advanced sensors feed real-time data to analytical systems that identify abnormal patterns long before catastrophic failure occurs. This approach requires integrating sensor data with historical performance records to establish meaningful baselines.

Utilizing Specialized Software and Data Analysis

Digital transformation reaches inspection protocols through purpose-built software solutions. These platforms standardize data collection, enabling inspectors to document findings with photos, measurements, and test results in structured formats. Machine learning algorithms process accumulated inspection data to detect subtle degradation patterns invisible to human analysts. The resulting insights allow organizations to optimize maintenance schedules and resource allocation while maintaining comprehensive digital audit trails.