Evaluating the advantages of forged versus cast wheels

Forging, a metalworking process involving shaping metal under compressive force, is a crucial step in wheel manufacturing. This process significantly enhances the material's strength and ductility, leading to a more robust and reliable wheel. By manipulating the metal's molecular structure, forging creates a denser, more homogenous material, reducing the likelihood of fractures and improving overall performance.

Forging techniques, including drop forging and press forging, offer distinct advantages. Drop forging is often preferred for its ability to create intricate shapes and complex designs, while press forging is more suitable for larger, simpler components. Each technique has its own set of advantages and disadvantages that must be considered in the context of the specific wheel design and production requirements.

The Role of Machining in Wheel Production

Machining plays a vital role in shaping and finishing wheels, refining the forged or cast components to precise specifications. From roughing out the basic form to creating intricate patterns and holes, machining ensures the wheel meets the required dimensions and tolerances. Different machining processes, such as turning, milling, and drilling, are used at various stages of production, contributing to the final product's quality and performance.

Heat Treatment for Enhanced Properties

Heat treatment is an indispensable step in the manufacturing process, altering the microstructure of the metal to enhance its desired properties. By carefully controlling the temperature and time of heating and cooling, the material's hardness, toughness, and fatigue resistance can be significantly improved. This process is critical for ensuring the wheel can withstand the stresses and loads imposed during operation.

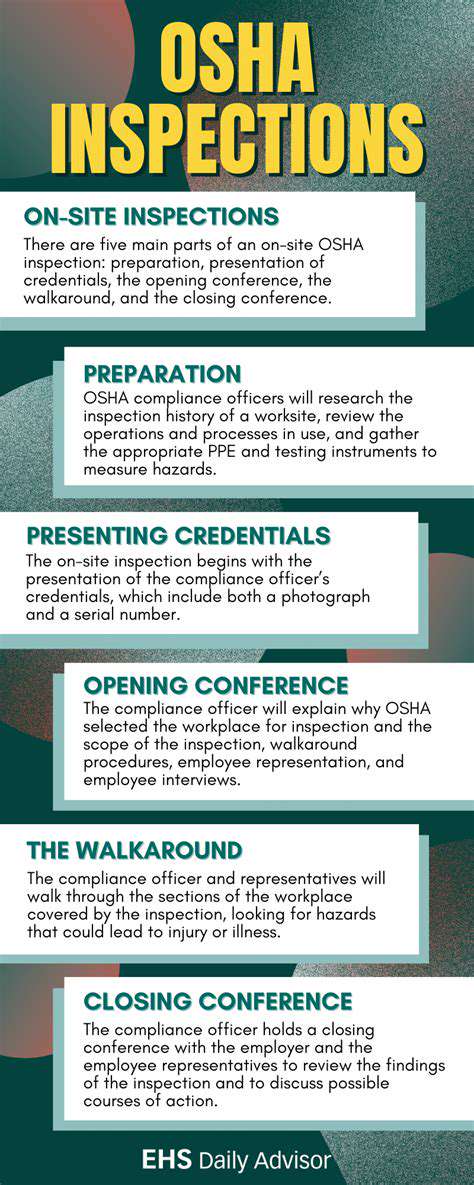

Inspection and Quality Control

Rigorous inspection and quality control measures are essential throughout the wheel manufacturing process. These measures ensure that each wheel meets the required specifications and standards. Non-destructive testing methods, such as ultrasonic testing and X-ray inspection, are often used to detect internal defects and ensure the integrity of the final product. This meticulous quality control process safeguards against potential failures and ensures the safety of the end-user.

Material Selection and its Impact on Wheel Design

Choosing the appropriate material is paramount in wheel manufacturing, as the material's properties directly impact the wheel's performance and durability. Factors such as strength, weight, corrosion resistance, and cost play crucial roles in the decision-making process. Different alloys and metals offer various combinations of these properties, and the selection process must carefully balance these competing demands. The chosen material greatly influences the wheel's ability to withstand various operating conditions and stresses.

Environmental Considerations in Wheel Manufacturing

Modern wheel manufacturing increasingly considers environmental factors. Sustainability concerns are driving the search for eco-friendly materials and manufacturing processes. Minimizing waste, optimizing energy consumption, and reducing harmful emissions are crucial aspects of responsible wheel production. Companies are exploring alternative materials and innovative techniques to lessen the environmental impact of wheel manufacturing, aligning with the growing demand for sustainable solutions.

Cast Wheels: The Budget-Friendly Alternative

Understanding Cast Wheels

Cast wheels, often overlooked in favor of more expensive forged options, offer a compelling balance of performance and affordability. They are manufactured by pouring molten metal into a mold, allowing for intricate designs and a wide range of styles. This process, while less complex than forging, still yields a strong and durable wheel, ideal for everyday driving and various performance applications.

The material composition of cast wheels is carefully selected to achieve the desired strength and weight ratio. This means a cast wheel can provide a similar level of performance to a forged wheel while keeping costs significantly lower.

Forged vs. Cast: A Direct Comparison

Forged wheels, renowned for their strength and light weight, are often the benchmark for high-performance applications. However, their significantly higher cost makes them less accessible to many budget-conscious buyers. Cast wheels, while not quite as light as their forged counterparts, offer a robust alternative that can often meet the performance demands of everyday use.

Forged wheels are created by hammering metal into shape, a process that inherently results in a denser structure. This density, while offering superior strength, translates into a higher price tag compared to the casting process.

Performance Considerations

Cast wheels, while not as lightweight as forged options, can still provide impressive performance characteristics, especially in terms of handling and braking. Their strength and durability are often sufficient for everyday driving, track days, and even spirited highway cruising. The key to performance with cast wheels lies in proper material selection and design.

The design of the wheel, including the spoke patterns and overall shape, is crucial for achieving the desired balance of strength, weight, and aesthetics. This is an important factor to consider when choosing a specific cast wheel model.

Durability and Longevity

Cast wheels are known for their remarkable durability. They can withstand the rigors of everyday driving, including potholes, curbs, and occasional impacts. Proper maintenance, including regular cleaning and inspection, can significantly extend the lifespan of a cast wheel set.

The manufacturing process used for cast wheels often results in a sturdy and resilient product, capable of withstanding the stresses of normal use. This durability makes them a reliable and long-lasting option for most drivers.

Aesthetics and Customization

Cast wheels are available in a wide array of styles, finishes, and designs. From classic five-spoke patterns to modern multi-spoke designs, there's a cast wheel to complement nearly any vehicle's aesthetic. The customization options allow drivers to personalize their vehicles and express their individual style.

The diverse range of finishes, including polished, brushed, and painted options, allows drivers to match the wheel's look with their car's exterior color and personal preferences. This makes cast wheels an attractive choice for those seeking both performance and style.

Affordability and Value

One of the most significant advantages of cast wheels is their affordability. They represent a substantial cost savings compared to forged wheels, making them an attractive option for budget-conscious buyers. This lower price point allows more people to upgrade their vehicles' wheels without breaking the bank.

The cost-effectiveness of cast wheels is a significant factor for many consumers. The lower price point allows for a more accessible upgrade path, opening up a wider range of options for improving vehicle aesthetics and performance.

Maintenance and Care

Maintaining cast wheels is relatively straightforward. Regular cleaning and inspection are crucial to prevent corrosion and damage. Proper wheel balancing and tire pressure checks are also essential to ensure optimal performance and longevity. Following these simple maintenance steps can maximize the lifespan of your cast wheels.

In summary, proper care and maintenance are key to ensuring the longevity of any wheel, cast or forged. This includes regular cleaning to remove road debris and salt, checking for any signs of damage, and maintaining the recommended tire pressure. These preventative measures will enhance the lifespan and performance of your wheels.

Performance and Handling Considerations

Performance Optimization Strategies

Optimizing performance is crucial for a seamless user experience. A well-performing application ensures users can interact with it quickly and efficiently, leading to higher satisfaction and reduced frustration. This involves a multifaceted approach, considering factors like database queries, code efficiency, and server responsiveness. Careful planning in the design phase can significantly impact the final performance of the application. Developers should prioritize using optimized algorithms and data structures to minimize processing time. Careful attention to caching mechanisms can also dramatically improve response times.

Furthermore, regular performance testing and monitoring are essential to identify and address bottlenecks. By analyzing performance metrics, developers can pinpoint areas for improvement and proactively resolve issues before they impact users. Tools and techniques like profiling, load testing, and benchmarking can provide valuable insights into application behavior under various conditions. This data-driven approach allows for continuous improvement and ensures the application remains responsive even under high load conditions. Implementing a robust monitoring system allows for proactive identification of potential problems.

Handling Diverse User Needs

A successful application must be able to handle a wide range of user needs and preferences. This encompasses various factors, from different operating systems and devices to varying levels of technical expertise. Providing a consistent experience across all platforms is paramount. Accessibility features are crucial for users with disabilities, ensuring that the application is usable and enjoyable for everyone. Designing for inclusivity requires a comprehensive understanding of diverse user needs and the ability to adapt the application accordingly.

Providing options for customization is another key aspect of handling diverse needs. Users should be able to tailor the application to their specific preferences. This could involve choosing different themes, layouts, or functionalities. Offering multiple input methods, such as keyboard, mouse, and touch input, further enhances usability and accessibility. Offering alternative ways to interact with the application ensures that it can be used by a wide variety of users.

Consideration should also be given to user support and documentation. Clear and comprehensive documentation, coupled with readily available support channels, empowers users to effectively utilize the application. This reduces the need for extensive user training and minimizes the chances of user frustration. Thorough documentation ensures that users can effectively navigate and use the application without assistance, contributing to a positive user experience.

Addressing Potential Issues

Anticipating and addressing potential issues is essential for maintaining a stable and reliable application. This involves careful planning and testing to identify vulnerabilities and weaknesses. Proactive measures, like security audits and penetration testing, can help prevent malicious attacks and data breaches. Thorough testing across different scenarios, such as various input values, network conditions, and system configurations, can help uncover potential problems. Early detection of issues is critical.

Developing robust error handling mechanisms is also crucial. This ensures that the application can gracefully handle unexpected events or errors. Implementing proper error logging and reporting mechanisms allows for accurate identification and resolution of issues, which is essential to preventing user frustration and maintaining a positive user experience. Error handling is also important for maintaining data integrity and application stability. Thorough debugging and testing are vital to ensuring a resilient and reliable application.