Exploring innovative solutions for vehicle noise reduction

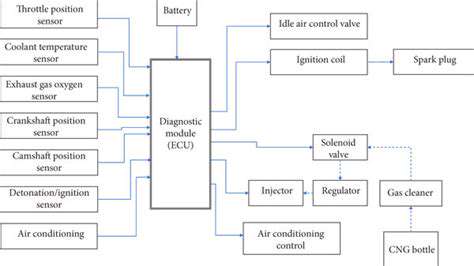

- Precision fuel injection timing

- Optimized spark plug placement

- Variable valve timing systems

- Active engine mounts

Modern control systems constantly adjust these parameters based on real-time operating conditions. This dynamic optimization ensures smooth operation whether cruising or accelerating hard. The latest direct injection systems achieve remarkably consistent combustion, eliminating the rough running that plagued earlier designs.

Exhaust system tuning has also become incredibly sophisticated. Helmholtz resonators and carefully designed muffler internals target specific frequency ranges. The result is an exhaust note that's both sporty when pushed yet unobtrusive during normal driving.

Cutting-Edge Tire Technologies for Silent Mobility

Material Innovations in Tire Construction

The quest for quieter tires has driven remarkable advancements in rubber compounds. Silica-infused tread formulations provide excellent grip while dramatically reducing rolling noise. Specialized foam layers bonded to the inner tire surface absorb vibrations before they reach the wheel well. These solutions work in harmony to create tires that are both high-performing and exceptionally quiet.

Manufacturers now employ nanotechnology to engineer materials at the molecular level. This allows for precise control over properties like hysteresis and damping characteristics. The latest premium tires feature multiple compound zones that optimize performance for different parts of the tread pattern.

The Art and Science of Tread Design

Tread pattern engineering has evolved into a highly specialized discipline. Computer modeling helps designers create patterns that:

- Channel water efficiently

- Minimize air pumping noise

- Reduce tread block vibration

- Maintain consistent contact pressure

The most advanced designs feature variable pitch sequences that break up harmonic noise patterns. This approach essentially randomizes the sound signature, making it less noticeable to human ears. Some manufacturers even tailor tread designs to specific vehicle applications for optimal noise performance.

Integrated Vehicle Acoustic Engineering

Tire noise reduction doesn't stop at the rubber. Automakers now consider the entire wheel assembly as an acoustic system. Lightweight alloy wheels with optimized stiffness help prevent noise amplification. Suspension bushings incorporate advanced elastomers that filter high-frequency vibrations.

The most sophisticated systems use active noise cancellation technology to counteract tire noise in real time. Microphones detect incoming noise which the system then counters with precisely timed sound waves. This holistic approach delivers the quietest cabins ever achieved in mass-produced vehicles.

The Future of Silent Mobility

Emerging technologies promise even greater advances in noise reduction. Researchers are exploring:

- Shape-memory alloys that adapt to road conditions

- Self-healing compounds that maintain optimal performance

- Integrated sensors that adjust inflation pressure dynamically

These innovations will continue pushing the boundaries of what's possible in tire technology. The ultimate goal remains creating tires that deliver maximum performance with minimal acoustic intrusion. As these technologies mature, they'll help create vehicles that are both thrilling to drive and exceptionally refined.