Driveline Bearings: Smooth Power Delivery

The Critical Role of Driveline Bearings in Power Transmission

Understanding Driveline Bearing Function

Driveline bearings are crucial components in power transmission systems, acting as the silent but vital link between rotating shafts and the rest of the system. They enable smooth, efficient rotation by minimizing friction and wear. Properly functioning driveline bearings are essential for maintaining consistent power output and preventing costly damage to the entire driveline system. These bearings play a critical role in various applications, from automotive transmissions to industrial machinery.

Types of Driveline Bearings and Their Applications

Several types of driveline bearings exist, each designed for specific applications and load conditions. Ball bearings, often used in automotive drivetrains, provide high load capacity and low friction. Roller bearings, on the other hand, excel in situations with high radial loads, making them suitable for heavy-duty machinery. The specific type selected depends on the specific demands of the application, including the load, speed, and operating environment.

Choosing the correct type of bearing is paramount for longevity and performance. Factors like the operating temperature range, the presence of contaminants, and the expected operating speed all influence the selection process. Careful consideration of these factors ensures the bearing can handle the required load and speed without premature failure.

Driveline Bearing Maintenance and Inspection

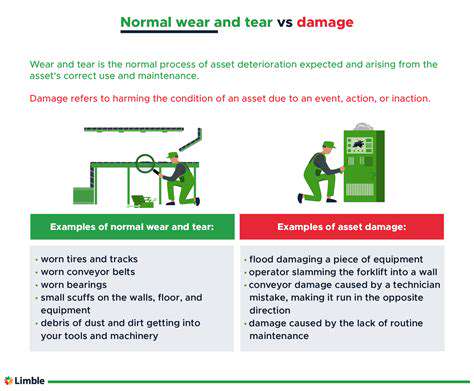

Regular maintenance and inspection are key to the longevity and reliable operation of driveline bearings. Visual inspections for signs of wear, damage, or excessive play are crucial. Monitoring vibration levels can also help detect early signs of potential problems. Lubrication schedules should be strictly adhered to, ensuring the bearings receive the correct type and amount of lubricant, maintaining optimal performance. Addressing any issues promptly can prevent costly repairs and downtime.

Impact of Driveline Bearing Failure on System Performance

Driveline bearing failure can have a significant and multifaceted impact on the entire power transmission system. Failure can lead to increased friction and noise, ultimately resulting in reduced efficiency and increased energy consumption. It can also cause catastrophic damage to other components, leading to costly repairs and potential downtime. Predictive maintenance strategies, focusing on early detection of potential issues, are crucial to minimizing the impact of bearing failure.

Advancements in Driveline Bearing Technology

Ongoing advancements in materials science and engineering have led to significant improvements in driveline bearing technology. New materials with enhanced load-bearing capabilities and corrosion resistance are being developed to extend the lifespan of these critical components. Innovative lubrication techniques and design improvements are also contributing to increased efficiency and reduced friction. These advancements ensure that driveline bearings continue to meet the evolving demands of modern power transmission systems.

Minimizing Friction for Enhanced Efficiency

Understanding the Role of Bearings in Driveline Systems

Driveline bearings are critical components in any vehicle's drivetrain, enabling smooth and efficient power transfer from the engine to the wheels. These bearings, often overlooked, play a vital role in minimizing friction and maximizing the lifespan of the entire system. Their precise design and robust construction are essential for maintaining optimal performance and preventing potential damage. Proper lubrication and regular maintenance are key to ensuring the continued functionality and reliability of these crucial components.

The continuous rotation and high-stress environment of the driveline components place significant demands on the bearings. Their ability to withstand these forces while maintaining consistent performance is a direct reflection of the quality and engineering of the bearing itself. Understanding the intricacies of these components is paramount for anyone involved in vehicle maintenance or repair. The smooth operation of the driveline is directly tied to the seamless performance of the bearings.

Minimizing Friction for Optimal Power Transfer

Friction is the enemy of efficiency in any mechanical system, and driveline bearings are no exception. Excessive friction leads to power loss, increased wear and tear on components, and ultimately, a reduction in overall performance. High-quality bearings, carefully selected for the specific application and operating conditions, are designed to minimize friction to a significant degree. This translates to a smoother, more responsive driveline and improved fuel economy.

The precise tolerances and carefully engineered surfaces of the bearings contribute to their low friction properties. By reducing the resistance between moving parts, bearings enable the driveline to transmit power with minimal energy loss. This optimization is crucial for both passenger vehicles and heavy-duty machinery, where power efficiency is paramount.

Impact of Bearing Selection on Driveline Longevity

The choice of bearings directly impacts the longevity of the entire driveline system. Selecting bearings that are appropriate for the specific application and operating conditions is crucial to ensure they can withstand the stresses and loads they will encounter. Using undersized or incorrectly specified bearings can lead to premature failure, resulting in costly repairs and downtime.

Factors such as the expected load, speed of rotation, and operating temperature must be considered when selecting bearings. A thorough understanding of these factors allows for the selection of bearings that are properly engineered to manage the specific demands of the driveline. This proactive approach ensures the driveline system remains operational for an extended period without costly interventions.

Bearing Maintenance and Lubrication Practices

Regular maintenance and proper lubrication are essential for ensuring the continued smooth operation and extended lifespan of driveline bearings. Proper lubrication reduces friction, prevents overheating, and protects the bearing surfaces from corrosion and wear. Following manufacturer recommendations for lubrication intervals and types is critical for optimal performance.

Routine inspections of the bearings for signs of damage or wear are just as important as regular lubrication. Early detection of potential issues allows for timely repairs, preventing more extensive damage and costly repairs down the road. By adhering to established maintenance protocols, the overall efficiency and reliability of the driveline are significantly enhanced.

Advanced Bearing Technologies for Enhanced Performance

Modern advancements in bearing technology have led to improved designs that enhance the performance and efficiency of driveline systems. Improvements in materials, manufacturing processes, and lubrication techniques have resulted in bearings that are more durable, reliable, and capable of handling even more demanding operating conditions.

These advancements often include features that optimize heat dissipation, reduce friction, and increase load capacity. Utilizing these advanced technologies leads to a more robust and efficient driveline, leading to improved performance and longevity. The continuous evolution of bearing technology is driving further improvements in driveline efficiency and reliability.