Analyzing the long term benefits of premium car fluids

Enhanced Cooling System Performance and Durability

Improved Heat Dissipation

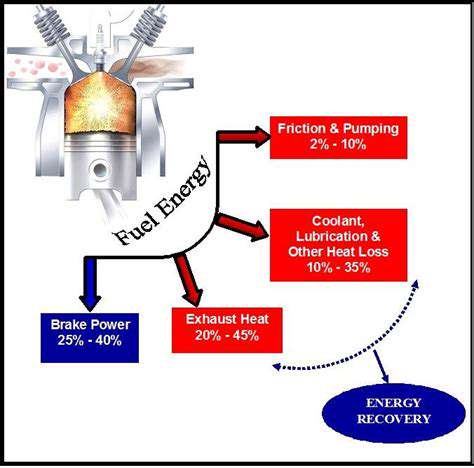

A meticulously designed cooling system is crucial for maintaining optimal performance and extending the lifespan of any device or machine. Enhanced heat dissipation mechanisms play a pivotal role in achieving this. By strategically employing advanced materials and innovative thermal designs, we can significantly reduce the temperature buildup within critical components. This translates to a reduction in thermal stress, which is a major contributor to component degradation over time. This proactive approach to heat management directly combats the detrimental effects of overheating, leading to a substantial improvement in overall reliability and longevity.

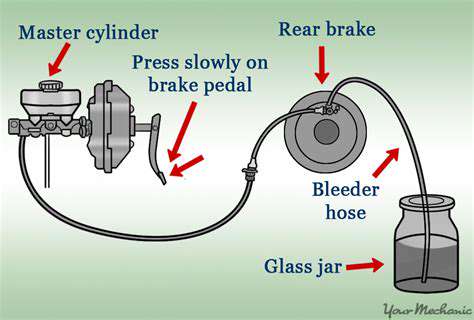

The use of specialized heat sinks, advanced cooling fluids, and optimized airflow patterns all contribute to a more efficient transfer of heat away from sensitive components. This allows the system to operate at peak performance while minimizing the risk of damage caused by excessive temperatures. The result is a more durable and reliable system, capable of enduring sustained high-performance operation without compromising its integrity.

Prolonged Component Life

One of the most significant long-term benefits of an enhanced cooling system is the marked increase in the lifespan of critical components. By actively managing heat, we can significantly reduce the rate at which components degrade due to thermal stress. This translates to fewer repairs, replacements, and downtime, ultimately leading to substantial cost savings over the product's entire operational cycle. The reduced thermal stress also extends the life of critical materials, preventing premature failure and ensuring consistent performance for years to come.

Components are less prone to warping, cracking, or other forms of degradation, maintaining their precision and functionality. The result is a more dependable system that can operate consistently over an extended period, significantly reducing the need for costly replacements and maintenance, thereby maximizing the return on investment.

Reduced Energy Consumption

An efficient cooling system can lead to lower energy consumption. When components overheat, systems often compensate by drawing more power to maintain operational parameters. By optimizing heat dissipation, the cooling system can maintain the desired temperature with less energy, resulting in reduced operating costs over the system's lifespan. This is particularly important for applications where energy efficiency is paramount and long-term operational costs are critical.

Minimizing the need for excessive cooling efforts can also lead to a more sustainable solution. Lower energy consumption directly contributes to a smaller environmental footprint, making the system a more environmentally friendly option in the long run. The positive impact on energy efficiency extends to the reduction of greenhouse gas emissions and the overall sustainability of the operation.

Minimized Downtime and Maintenance

A robust cooling system directly impacts the overall operational availability of a system. By reducing the risk of overheating-related failures, the system experiences significantly less downtime. This translates to higher productivity and efficiency over the long term. The reduced frequency of component failures and replacements translates into lower maintenance costs and fewer disruptions to the operational workflow.

Predictive maintenance strategies can also be more effectively implemented with improved cooling systems. By closely monitoring temperatures and using data analytics, potential issues can be identified and addressed before they lead to catastrophic failures. This proactive approach to maintenance minimizes unforeseen downtime and avoids costly repairs, leading to a more dependable system overall.