Practical advice for extending the service life of automotive seals

Choosing the Right Lubricant

Selecting the appropriate lubricant is crucial for optimal performance and longevity of any machine or mechanism. Different applications require different viscosities and chemical compositions. Understanding the operating environment, temperatures, and the materials involved is paramount. A lubricant that's too thick might hinder smooth operation, while one that's too thin could lead to excessive wear and tear. Proper selection requires careful consideration of these factors.

The lubricant must be compatible with the materials being lubricated. Incompatible lubricants can cause corrosion, degradation, and ultimately, failure. Consult manufacturers' specifications and guidelines to ensure compatibility and suitability for the specific task.

Proper Application Techniques

Applying lubricant effectively is just as important as choosing the right type. Using the correct amount, and distributing it evenly, is critical to ensuring that all moving parts receive adequate protection. Incorrect application can lead to wasted lubricant and potential damage. Proper application techniques also minimize the risk of contamination and ensure a consistent film thickness across the affected surfaces.

Consider the equipment's design and the specific lubrication points. Some applications may benefit from specialized tools or methods for optimal distribution. Employing the appropriate tools and techniques ensures efficient and thorough lubrication.

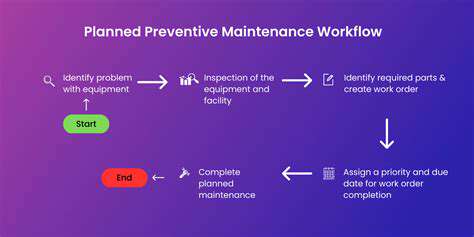

Frequency of Lubrication

Regular lubrication schedules are essential for maintaining equipment performance and preventing premature wear and tear. Ignoring scheduled maintenance can quickly lead to costly repairs and downtime. The frequency of lubrication depends on several factors, including the operating conditions, the type of equipment, and the lubricant's properties. Understanding these factors is crucial for developing a robust maintenance schedule.

Consult the manufacturer's recommendations for specific lubrication intervals. These recommendations are often based on extensive testing and real-world data to provide optimal maintenance strategies. Following these guidelines ensures the equipment operates reliably and efficiently.

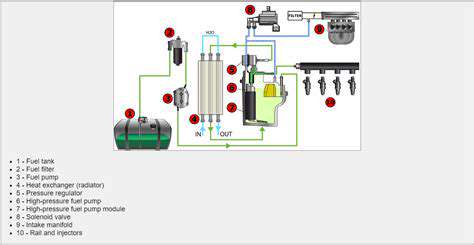

Lubrication System Design

A well-designed lubrication system is crucial for ensuring consistent and reliable lubrication throughout the machine. This system should be capable of delivering the correct lubricant to the right places at the right time. Proper system design minimizes wasted lubricant and maximizes its effectiveness, extending the machine's lifespan.

Consider factors like the equipment's size and complexity, the type of lubricant used, and the operating environment when designing the system. Thorough planning and meticulous implementation of a well-designed system are crucial for the long-term success of the machine.

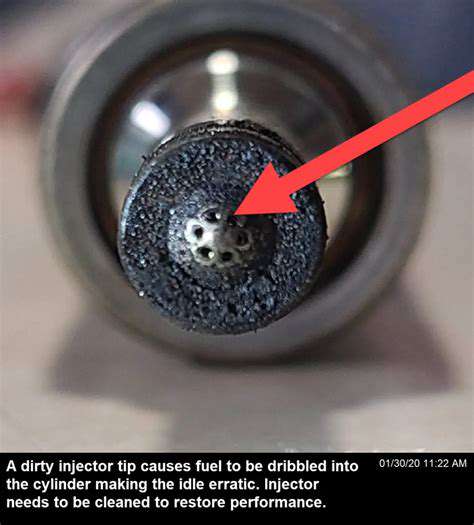

Monitoring Lubricant Condition

Regular monitoring of the lubricant's condition is vital for proactive maintenance. This involves checking for contaminants, changes in viscosity, and signs of degradation. Early detection of issues can prevent more significant problems and costly repairs in the future. Regular monitoring allows for prompt adjustments and ensures continuous optimal performance.

Using appropriate testing methods, such as viscosity checks, particle counts, and chemical analysis, provides valuable insights into the lubricant's health. Analyzing this data allows for informed decisions regarding maintenance, replacement, and further adjustments to the lubrication strategy.

Environmental Considerations

Environmental factors significantly influence lubrication strategies. Extreme temperatures, moisture, and dust can all impact the effectiveness of a lubricant. Understanding the specific environmental conditions is essential for selecting the right lubricant and maintenance schedule. Choosing a lubricant resistant to the specific environmental conditions is vital for long-term equipment health.

Environmental concerns extend to disposal and recycling of used lubricants. Proper disposal procedures protect the environment and comply with regulations. Following these procedures minimizes environmental impact and maintains sustainability.

Transforming your bedroom into a sleep sanctuary requires intentional design choices that go beyond mere aesthetics. The foundation of quality sleep lies in crafting an environment that actively supports relaxation. Soft, warm lighting replaces harsh overhead bulbs, while breathable bedding materials regulate temperature throughout the night. Many sleep experts recommend maintaining a room temperature between 60-67°F (15-19°C) for optimal sleep conditions.

Storage and Maintenance Practices for Extended Seal Life

Proper Storage Conditions

Maintaining optimal storage conditions is crucial for preserving the integrity of seals and extending their lifespan. Excessive heat, humidity, or direct sunlight can degrade the elastomeric compounds used in seal construction, leading to premature cracking, hardening, and ultimately, failure. Store seals in a cool, dry environment, ideally with a controlled temperature and humidity range. Avoid placing them near sources of intense heat or moisture, such as radiators, exposed pipes, or areas with high condensation.

Consider using protective packaging, such as airtight containers or sealed bags, to further safeguard seals from environmental contaminants like dust, dirt, and debris. Proper storage practices will significantly reduce the risk of damage and ensure seals retain their elasticity and functionality for extended periods.

Cleaning and Handling Procedures

Regular cleaning and careful handling are essential to prevent damage to seals. Use appropriate cleaning solvents or methods recommended by the manufacturer. Harsh chemicals or abrasive materials should be avoided as they can scratch or erode the seal surface, compromising its integrity. Always handle seals with clean, lint-free gloves to prevent contamination and maintain their pristine condition.

When moving seals, use appropriate lifting techniques to avoid bending, twisting, or applying excessive force that could induce stress fractures. Handle seals carefully to prevent damage during installation and maintenance procedures. These practices are critical for ensuring seals maintain their structural integrity and longevity.

Material Compatibility

Understanding the compatibility of the seal material with the surrounding environment and materials is vital. Different seal materials have varying tolerances for different chemicals, solvents, and temperatures. Improper material compatibility can lead to seal degradation and premature failure. Consulting the manufacturer's specifications for the specific seal material is crucial to ensure long-term performance and reliability.

Environmental Factors

Environmental factors significantly impact seal performance and longevity. Exposure to extreme temperatures, ultraviolet (UV) radiation, ozone, and other aggressive elements can accelerate seal degradation. Implementing protective measures, such as shielding from UV light or using specialized seal materials resistant to specific environmental factors, can enhance seal life.

Consider the expected operating conditions of the equipment where the seals will be used. Accurately predicting and mitigating the potential impact of environmental factors on seal performance is key to optimizing seal life.

Regular Inspection and Monitoring

Regular inspection and monitoring of seals are vital for early detection of potential issues and proactive maintenance. Visual inspections can identify signs of degradation, such as cracks, discoloration, or swelling. Regular monitoring of seal performance, such as pressure and temperature readings, can also help detect subtle changes that might indicate impending failure.

Proper Installation Techniques

Implementing proper installation techniques is essential for ensuring seal integrity and maximizing their lifespan. Adhering to manufacturer recommendations and using appropriate tools and techniques for installation will minimize the risk of damage during the assembly process. Incorrect installation can lead to premature seal failure, so careful attention to detail is critical.

Seal Replacement Schedule

Establishing a proactive seal replacement schedule based on usage, environmental factors, and manufacturer recommendations is crucial for maximizing seal life and preventing costly equipment downtime. Monitoring seal performance and understanding the predicted lifespan of different seal types will allow for timely replacement before failures occur, avoiding costly repairs or equipment replacements. This preventative approach will greatly extend the overall lifespan of the sealed systems.

Choosing High-Quality Seals: Investment in Long-Term Reliability

Choosing the Right Seal Material

Selecting the appropriate seal material is crucial for ensuring longevity and performance. Different materials exhibit varying resistance to chemicals, temperatures, and pressures. Understanding these properties is vital for preventing leaks, maintaining efficiency, and ultimately extending the lifespan of your equipment. For instance, choosing a seal made of a material resistant to the specific chemicals used in your application will prevent premature degradation and costly replacements.

Consider factors like the operating temperature range, the presence of corrosive substances, and the required pressure resistance. Selecting a material that complements these factors will significantly reduce the risk of seal failure. This proactive approach to material selection is often more cost-effective in the long run compared to addressing problems arising from poor initial choices.

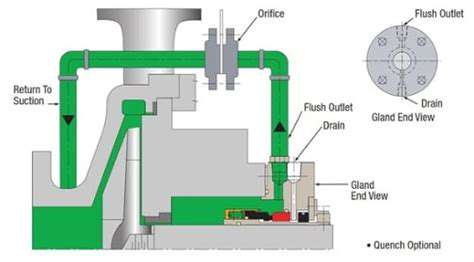

Understanding Seal Design and Construction

The design of a seal directly impacts its performance. Factors like the seal's cross-section, the materials used in its construction, and the manufacturing tolerances all contribute to its overall effectiveness. Careful consideration of these elements is vital for ensuring a tight seal and preventing leakage.

A well-designed seal will provide a reliable barrier against fluid flow. A poorly constructed seal, on the other hand, may leak, leading to equipment malfunction and potential environmental hazards. Understanding the intricacies of seal design is an essential step in the selection process.

Evaluating Seal Installation Procedures

Proper installation is just as important as the quality of the seal itself. Incorrect installation methods can compromise the seal's integrity, leading to leaks and potentially damaging equipment. Following the manufacturer's instructions meticulously is crucial for achieving a successful installation.

Thoroughness during installation is key to a long-lasting seal. A properly installed seal will perform as intended, minimizing the risk of leaks and maintaining equipment efficiency. Neglecting proper installation procedures can result in premature seal failure and costly repairs.

Considering Seal Compatibility

Compatibility with other components in the system is another crucial aspect to consider when selecting seals. For instance, the seal material should be compatible with the fluids or gases it will be exposed to, as well as with any lubricants or other materials in contact with it. This will prevent undesirable chemical reactions or material degradation.

Addressing Seal Maintenance and Replacement

Regular maintenance and timely replacement of seals are essential for optimal equipment performance and safety. Establishing a proactive maintenance schedule will help identify potential issues before they escalate into major problems. This includes inspecting seals for signs of wear and tear, such as cracks, swelling, or deformation. Routine maintenance, coupled with a clear understanding of seal lifespan, are key components in preventing costly equipment downtime.