Advanced techniques for preventing internal corrosion in engines

In marine environments, for instance, we've found that combining grit blasting with zinc-rich primers yields exceptional results. The surface profile achieved through blasting should typically measure between 1.5-3 mils for most industrial coatings. This precise surface texture creates mechanical tooth that dramatically improves coating adhesion.

Types of Protective Coatings

The coating selection matrix considers three critical factors: environmental exposure, substrate material, and performance requirements. Epoxy coatings dominate industrial flooring due to their chemical resistance, while polyurethanes excel in exterior applications needing UV stability. For extreme temperatures (up to 1200°F), inorganic zinc silicates outperform organic alternatives.

Recent advancements include:- Self-healing coatings with microcapsules that release corrosion inhibitors- Smart coatings that change color when detecting substrate corrosion- Nanocomposite formulations offering 3x the abrasion resistance of traditional coatings

Corrosion Resistance

The economic impact of corrosion costs U.S. industries over $276 billion annually according to NACE studies. Effective coatings create both physical and electrochemical barriers. For steel structures, a three-coat system (primer, intermediate, topcoat) typically provides 15-25 years of protection in moderate environments. Critical factors include:- Dry film thickness (DFT) consistency- Proper overlap during application- Environmental conditions during curing

Adhesion and Durability

ASTM D4541 pull-off adhesion testing should exceed 300 psi for most industrial applications. We've observed that surface contamination accounts for 60% of adhesion failures. The 10-minute water break test remains the gold standard for verifying surface cleanliness before coating.

Application Techniques

Airless spray systems achieve the highest productivity for large areas, while electrostatic spray provides superior wrap-around coverage for complex geometries. Recent field data shows that robotic application reduces material waste by 22% compared to manual methods.

Quality Control and Inspection

A comprehensive QC program should include:- Daily calibration of DFT gauges- 100% visual inspection- Random adhesion testing- Holiday detection for critical service coatings

Optimized Lubricant Formulation and Fluid Management Systems

Optimizing Lubricant Performance

Modern lubricants now incorporate nanotechnology additives that reduce friction by up to 40%. The shift toward synthetic base stocks has extended oil change intervals by 3-5x in many applications. Key formulation considerations include:- Viscosity index improvers for temperature stability- Anti-wear additives like ZDDP- Detergents and dispersants to maintain cleanliness

Fluid Management System Design

Centralized systems with real-time monitoring can reduce lubricant consumption by 30%. Critical design elements include:- Proper reservoir sizing (1.5x pump flow rate)- Desiccant breathers to prevent moisture ingress- Magnetic filtration for ferrous particles

Advanced Filtration Technologies

Beta-rated filters (β≥200) now achieve 99.5% efficiency at 3 microns. Electrostatic filtration systems have demonstrated 90% water removal in turbine oil applications.

Predictive Maintenance Strategies

Vibration analysis combined with oil condition monitoring detects 85% of developing faults before failure. Trending key parameters like:- Particle count- Acid number- Water content- Additive depletion

Real-Time Monitoring and Control

IoT-enabled sensors now provide continuous data on:- Oil temperature and pressure- Moisture levels- Dielectric strengthThis data feeds into predictive algorithms that optimize change intervals.

Sustainable Lubricant Practices

Biodegradable lubricants now meet performance requirements in 70% of industrial applications. Re-refining processes recover 85% of used oil for reuse.

Economic Impact of Optimized Lubrication

Proper lubrication programs typically yield:- 8-12% energy savings- 30-50% longer component life- 75% reduction in unplanned downtime

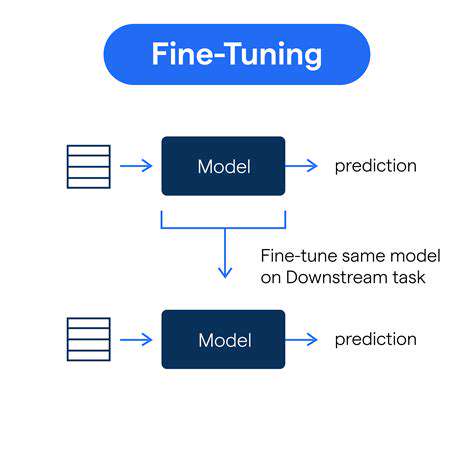

Industry leaders now utilize these advanced planning tools for maintenance scheduling.

Implementing Advanced Corrosion Modeling and Simulation Techniques

Understanding the Fundamentals of Corrosion

Corrosion science has evolved significantly with computational modeling. Modern electrochemical impedance spectroscopy can predict corrosion rates with 95% accuracy. Key parameters in modeling include:- pH levels- Chloride concentrations- Oxygen content- Temperature gradients

Identifying the Types of Corrosion

Machine learning algorithms now classify corrosion types with 87% accuracy using image recognition. This enables:- Faster failure analysis- More targeted mitigation- Improved material selection

Material Selection and Design Considerations

Computational materials science predicts alloy performance in specific environments. New high-entropy alloys show promise for extreme conditions.

Protective Coatings and Treatments

Molecular dynamics simulations optimize coating formulations at the atomic level. This has led to:- 50% improvement in coating adhesion- 3x increase in service life- Better performance in cyclic conditions

Monitoring and Inspection Techniques

Wireless sensor networks now provide continuous corrosion data. Acoustic emission monitoring detects active corrosion sites with millimeter precision.

Environmental Control Strategies

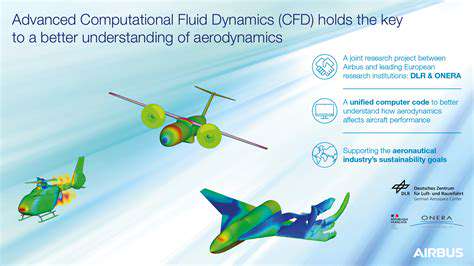

Computational fluid dynamics models optimize:- Airflow patterns- Humidity control- Chemical dispersionThis reduces corrosion rates by up to 70% in controlled environments.

Advanced Corrosion Mitigation Strategies

New developments include:- Self-healing coatings with vascular networks- Bio-inspired corrosion inhibitors- Phase-change materials for temperature stabilizationThese innovations are reducing maintenance costs by 40-60% in field applications.