Why regular inspection of exhaust systems is essential

Environmental Factors

Nature doesn't follow project schedules. Seasonal weather patterns, site topography, and even local wildlife can dramatically affect workplace safety. A coastal construction project faces different challenges than one in an urban setting—from saltwater corrosion to hurricane preparedness. Smart teams don't just react to environmental conditions; they plan for them from day one.

Detailed environmental assessments should become standard practice during project planning phases.

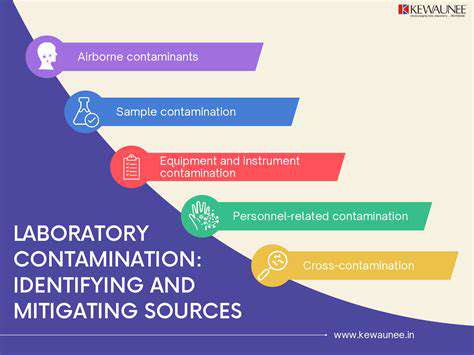

Equipment and Material Risks

Tools and materials carry inherent risks that demand respect. Whether it's heavy machinery with pinch points or chemicals requiring special handling, each element requires specific safety protocols. Regular equipment inspections and material safety training form the backbone of effective hazard prevention.

Human Error and Procedures

Even the best systems can't eliminate human fallibility. The most common workplace accidents often stem from simple mistakes—a momentary lapse in concentration or an assumption that shortcuts are safe. That's why comprehensive training programs and clear, accessible procedures make such a difference. When safety becomes second nature, risks decrease dramatically.

Daily safety briefings and visible reminder systems help maintain awareness throughout a project's duration.

Emergency Response Planning

Hope isn't a strategy when emergencies strike. Detailed response plans—regularly practiced and updated—turn chaos into coordinated action. From medical emergencies to environmental spills, prepared teams respond faster and more effectively. Quarterly drills keep response protocols fresh in everyone's mind, ensuring readiness when seconds count.

Minimizing Environmental Impact and Meeting Regulatory Standards

Minimizing Waste Generation

The most effective waste management strategy begins before waste exists. Innovative design approaches now focus on creating products that last longer and can be easily repaired. Forward-thinking companies are proving that sustainability and profitability can coexist through clever material choices and modular designs. These strategies don't just reduce landfill contributions—they often lower production costs too.

Modern waste reduction looks beyond simple recycling. The circular economy model represents a fundamental shift in how we view materials—not as disposable, but as valuable resources to be continuously reused. This approach transforms waste streams into supply chains, creating closed-loop systems that benefit both businesses and the environment.

Efficient Resource Utilization

Resource efficiency has evolved from cost-saving measure to environmental imperative. Smart building technologies now optimize energy use in real-time, while precision agriculture techniques maximize crop yields with minimal inputs. These innovations demonstrate how technological advancement can drive environmental progress without sacrificing productivity.

Water conservation efforts have moved beyond simple low-flow fixtures. Industrial facilities now implement sophisticated water recycling systems, while farmers employ moisture sensors to optimize irrigation. These technologies prove that careful resource management can simultaneously boost efficiency and reduce environmental impact.

Promoting Sustainable Consumption and Production

Consumers now wield significant power through their purchasing decisions. An informed public increasingly supports companies that demonstrate genuine environmental commitment through transparent supply chains and verifiable sustainability claims. This market shift is driving meaningful change across industries.

Manufacturers are responding with innovative solutions—from biodegradable packaging to energy-efficient production methods. The most progressive companies now view sustainability not as a cost center, but as a driver of innovation and competitive advantage. This mindset shift is creating products that satisfy consumer demand while protecting ecosystems.

Material science breakthroughs are enabling remarkable substitutions—mushroom-based packaging replacing styrofoam, or algae-derived plastics replacing petroleum-based versions. These innovations demonstrate that environmental responsibility can spark creativity rather than limit possibilities.