Identifying and resolving common starter motor problems

Before panicking, try this simple fix: clean and tighten those battery terminals. If the stubborn clicking continues, it's time to call in a professional. Ignoring these warning sounds could leave you stranded when you least expect it.

Difficulty Cranking or Slow Cranking

When your engine turns over sluggishly like it's moving through molasses, you're likely dealing with a starter issue. This frustrating symptom might come from a weak battery that can't deliver enough juice, a starter motor on its last legs, or problematic electrical connections. That extra second or two of cranking time is your vehicle's way of begging for attention.

A starter motor nearing the end of its lifespan often struggles internally, sometimes accompanied by ominous clicking or grinding noises. Pro tip: Address slow cranking immediately - putting it off could mean costly repairs later when the starter fails completely.

Grinding or Grinding Sounds

That awful metal-on-metal grinding noise during startup isn't just annoying - it's a red alert. This harsh sound usually means your starter's gears are either worn down or misaligned, potentially causing damage every time you start the car. Whether it's constant or comes and goes, this symptom demands immediate attention.

Continuing to operate with this issue risks serious damage to both your starter and engine components. The repair bill only grows the longer you wait - schedule a mechanic visit at the first sign of grinding.

No Crank at All

When turning the key yields absolute silence, you're facing every driver's nightmare. This complete failure to crank could indicate a dead battery, failed starter motor, or serious electrical issues. Safety first: Before troubleshooting, ensure your vehicle is in park or neutral with the parking brake engaged.

Start with basic checks - battery terminals, connections, and visible wiring. If these look good, it's time for professional diagnostics to prevent further damage and get you back on the road safely.

Analyzing Starter Motor Operation Principles

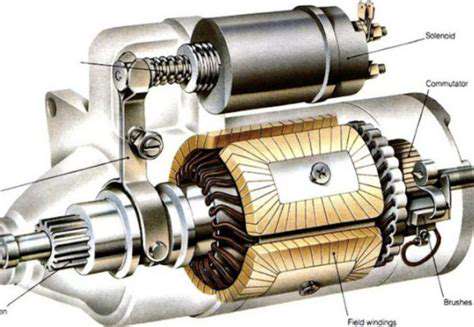

Understanding the Basic Components

The starter motor serves as your engine's wake-up call, transforming electrical energy into the mechanical motion needed to start combustion. At its heart lies the armature - a spinning core of copper windings that does the heavy lifting. Working alongside it, the solenoid acts as the system's switchboard operator, coordinating the connection between starter and engine.

Proper maintenance of these components ensures reliable starts for years to come. When any part fails, your morning commute could turn into an unexpected day off.

The Role of the Solenoid

This unsung hero of your starting system performs two crucial jobs simultaneously. When you turn the key, it both completes the high-current circuit to the starter motor and physically engages the starter gear with the engine's flywheel. Its spring-loaded disengagement mechanism is equally important - preventing damage once the engine starts running independently.

Electrical Circuitry and Power Supply

Your starter motor demands more electrical current than any other vehicle system - often over 200 amps during cranking. That's why clean, tight connections throughout the circuit are non-negotiable for reliable operation. Corrosion or loose wiring anywhere in this high-current path can spell trouble on cold mornings.

The Engagement Mechanism

The precision dance between starter gear and flywheel happens in milliseconds but requires perfect timing. Too early or late engagement causes that dreaded grinding noise, while failure to engage means no start at all. Modern starters use sophisticated designs to ensure smooth, reliable engagement every time.

Operational Sequence During Starting

From key turn to engine roar happens in a carefully choreographed sequence: electrical signal activates solenoid, solenoid engages gear and powers motor, motor spins engine until combustion takes over. Understanding this sequence helps diagnose where problems occur when starting fails.

Common Issues and Troubleshooting

Most starting problems fall into three categories: electrical (battery/connections), mechanical (gears/bearings), or solenoid-related. A methodical approach testing each component saves time and money compared to random part replacements.

Maintenance and Prevention

Regular battery checks and terminal cleaning provide the cheapest insurance against starting problems. For the starter itself, listen for changes in sound and note any slower cranking - these early warnings allow proactive replacement before failure.

Inspecting Starter Motor Components for Wear and Tear

Inspecting the Starter Motor Solenoid

The solenoid serves as both switch and actuator - making it the starter system's most failure-prone component. Look for telltale signs like cracked housing, corroded terminals, or melted plastic. Professional testing can verify if weak activation or sticking is occurring internally.

Evaluating the Starter Motor Gear and Drive

Worn or chipped gear teeth create that distinctive grinding noise during engagement. More concerning, metal fragments from damaged gears can circulate through your engine with catastrophic results. Also check the drive mechanism moves freely without binding - resistance here often precedes complete failure.

Assessing the Starter Motor's Electrical Connections and Wiring

Heat and vibration take their toll on starter wiring over time. Look for cracked insulation, green corrosion on terminals, or melted wire jackets indicating overheating. Remember: the starter draws more current than your entire house's lighting circuits - proper connections are critical for safety and reliability.