Key factors affecting fuel pump performance and longevity

Fuel Pressure and Flow Rate: Maintaining Optimal Conditions

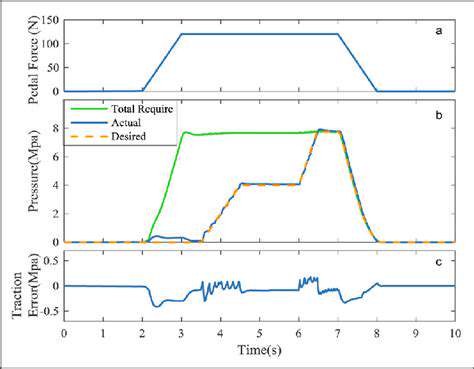

Understanding Fuel Pressure

Fuel pressure, the lifeblood of internal combustion engines, represents the vital force pushing fuel through the system. Without proper pressure regulation, even the most advanced engines become unreliable. This invisible hand guides fuel to combustion chambers with clockwork precision, where it transforms into motion. When pressure falters, engines cough and sputter like tired old machines. Mechanics often trace mysterious performance issues back to this single factor, making its mastery essential for any vehicle owner.

Fuel Flow Rate: The Engine's Fuel Intake

Imagine your engine as a living organism constantly adjusting its appetite. The fuel flow rate measures this hunger precisely - too little leaves the engine gasping for power, while too much drowns its potential. Modern engines dance on this razor's edge, balancing consumption against demand with computer-controlled precision. This delicate equilibrium depends on multiple factors: the fuel pump's heartbeat, injector precision, and the engine's ever-changing rhythm. Get it wrong, and you'll feel it in your wallet through wasted fuel or in your garage through costly repairs.

The Role of Fuel Injectors

Fuel injectors serve as the system's master chefs, transforming liquid fuel into a fine culinary mist perfect for combustion. Their microscopic nozzles, finer than human hair, operate with Swiss watch precision. When clogged or worn, these precision instruments become crude squirt guns, wasting fuel and robbing power. The difference between a clean injector and a dirty one can mean night-and-day performance changes. Regular maintenance keeps these critical components working like new, preserving both engine responsiveness and fuel efficiency.

Impact of Engine Speed and Load

Engines communicate their needs constantly through changing speeds and loads. Climbing a steep hill? The system responds with increased fuel flow. Cruising downhill? It scales back like a careful accountant. This dynamic conversation between engine and fuel system happens hundreds of times per minute, invisible to drivers but critical to performance. Understanding this relationship helps diagnose why a vehicle might struggle under specific conditions while running perfectly in others.

Pressure Sensors and Their Function

Modern vehicles employ sophisticated pressure sensors as their nervous system, constantly monitoring fuel delivery. These unsung heroes work tirelessly, sending thousands of data points to the engine's brain every minute. When these sensors fail, the engine flies blind, potentially causing expensive damage before the driver notices anything wrong. Their small size belies their importance - like canaries in a coal mine, they provide early warning of developing system issues.

Consequences of Imbalances in Pressure and Flow

Fuel system imbalances create a cascade of problems. Imagine trying to drink a milkshake through a straw that randomly changes size - sometimes barely a trickle, sometimes a firehose. That's what engines endure when pressure and flow fall out of sync. The results manifest in subtle ways at first - slightly reduced mileage, hesitation during acceleration. Left unchecked, these minor issues grow into major repairs. Catching them early saves both money and headaches down the road.

Just as cardiovascular exercise maintains human health, proper fuel system maintenance preserves vehicle vitality.