The impact of synthetic lubricants on transmission efficiency

Improved Heat Resistance

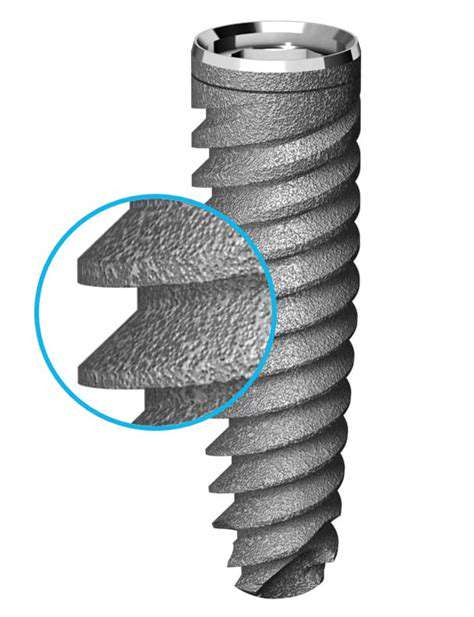

Modern thermal stability enhancements play a pivotal role across industries, especially where high-temperature operations are routine. Components benefiting from these advancements demonstrate remarkable longevity, as they endure elevated temperatures without rapid deterioration. Industries relying on such innovations experience fewer operational disruptions and lower maintenance expenses due to this breakthrough. While the science behind these improvements involves intricate material science, the practical benefits are immediately measurable.

Cutting-edge production techniques combined with novel material formulations create this exceptional heat tolerance. These technological leaps enable materials to preserve their structural integrity under thermal stress, preventing early failures while maintaining peak performance. The resulting operational savings and reliability improvements make this advancement particularly valuable for mission-critical applications.

Reduced Degradation Rate

Superior thermal stability fundamentally alters material degradation timelines in high-heat environments. Components now operate effectively for extended durations before requiring replacement, thanks to this slowed breakdown process. The correlation between enhanced thermal resistance and prolonged material viability creates new possibilities for continuous operation in extreme conditions. Industries with demanding operational requirements particularly benefit from this characteristic.

Where component failure could trigger costly consequences, this degradation resistance proves invaluable. High-temperature applications especially benefit, as materials face relentless thermal challenges without compromising performance. The extended service intervals resulting from this innovation translate directly to reduced operational downtime and optimized equipment utilization.

Extended Operational Lifespan

The most tangible benefit of advanced thermal stability manifests in dramatically lengthened component lifecycles. This technological progress creates substantial cost reductions through decreased maintenance frequency and part replacement needs. Extended service periods between interventions generate significant financial savings while boosting system reliability. The cumulative effect enhances overall operational efficiency across entire production systems.

This longevity proves particularly advantageous where component access proves difficult or replacement procedures require extensive downtime. Industrial operations demanding uninterrupted production find this characteristic absolutely essential for maintaining output targets.

Improved Material Properties at High Temperatures

Contemporary thermal stability advancements preserve critical material characteristics even under extreme heat exposure. Mechanical strength, structural rigidity, and dimensional accuracy all maintain their specifications far beyond traditional limits. These preserved properties ensure components continue functioning as designed despite challenging thermal environments. The molecular architecture's resilience under thermal stress forms the foundation of these performance benefits.

Applications and Industries Benefiting from Enhanced Thermal Stability

Multiple industrial sectors leverage these thermal stability improvements, including aviation, automotive manufacturing, power generation, and heavy industry. Aircraft systems benefit through components that withstand the intense heat of flight operations. Automotive applications gain from more durable engine parts capable of handling extreme operating temperatures. Energy infrastructure utilizes these materials in power plant components where heat resistance proves critical. Industrial equipment manufacturers incorporate these advancements to create machinery capable of withstanding punishing production environments.

The operational improvements directly impact efficiency metrics, maintenance budgets, and component replacement cycles. These material innovations have become indispensable for ensuring operational safety, maximizing efficiency, and guaranteeing reliability in demanding applications.

Reduced Friction and Energy Loss: Maximizing Power Transfer

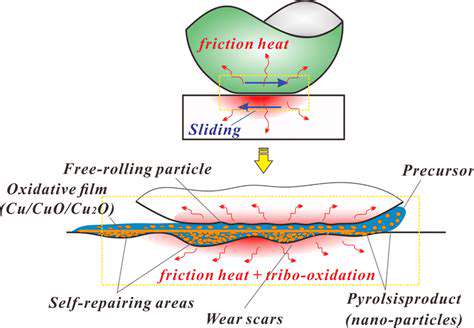

Minimizing Resistance for Optimal Performance

Engineered synthetic materials demonstrate inherently lower friction coefficients than conventional alternatives. This characteristic directly translates to more efficient energy transmission with minimized parasitic losses. The molecular uniformity and surface perfection characteristic of these materials facilitate smoother energy flow, simultaneously enhancing performance while reducing mechanical wear.

Enhanced Conductivity for Faster Transfer

Select synthetic formulations achieve exceptional electrical conduction properties. This enables rapid, efficient electricity movement from generation to consumption points with minimal transmission lag. The conductivity improvements dramatically reduce resistive losses, converting more input energy into useful output rather than wasteful heat dissipation.

Improved Material Flexibility and Adaptability

The malleability and customization potential of advanced synthetics permits innovative power system designs. Engineers can create optimized configurations that precisely match application requirements across diverse operating environments. This design flexibility enables tailored solutions that traditional materials cannot provide, opening new possibilities in power transmission technology.

Reduced Thermal Dissipation

Certain synthetic compounds exhibit extraordinary thermal management properties, significantly lowering heat generation during power transfer. This characteristic proves crucial in high-capacity systems where thermal buildup could compromise operation. By minimizing energy conversion to waste heat, more usable power reaches its intended destination.

Lightweight Solutions for Enhanced Efficiency

The reduced mass of advanced synthetic materials creates secondary efficiency gains in power transmission systems. Lighter components require less energy to operate and support, creating compounding efficiency improvements throughout the system. This mass advantage proves particularly valuable in mobile applications and aerospace implementations where weight directly impacts performance.

Customizable Properties for Specific Needs

The tunable characteristics of modern synthetic materials allow precision engineering for specialized applications. Engineers can optimize strength, durability, and conductivity parameters to create ideal solutions for unique power transmission challenges. This customization capability ensures optimal performance across an expanding range of industrial applications.

Cost-Effectiveness and Scalability

The economic advantages of synthetic material production contribute significantly to their widespread adoption. Large-scale manufacturing processes deliver these advanced materials at competitive price points compared to conventional alternatives. This cost efficiency, combined with performance benefits, drives their increasing utilization across power transmission applications.