Key steps in preventing carbon buildup on throttle bodies

Understanding the Mechanisms of Carbon Deposits

Those stubborn black accumulations plaguing engines and industrial equipment? They're not just cosmetic nuisances. Carbon deposits represent the physical manifestation of inefficient combustion, where hydrocarbon fuels fail to burn completely. The chemistry behind this phenomenon reveals why some engines seem prone to buildup while others remain relatively clean. When combustion chambers don't achieve perfect stoichiometric ratios - that ideal balance of fuel and oxygen - leftover carbon molecules begin their slow conquest of engine surfaces.

These microscopic invaders don't play fair either. Incomplete combustion creates sticky hydrocarbon chains that cling tenaciously to metal surfaces. Over successive combustion cycles, these particles polymerize into increasingly complex structures. The result? That familiar black crust that reduces heat transfer, disrupts airflow, and eventually compromises performance. Different engines show varying susceptibility based on their combustion chamber designs and operating temperatures.

Fuel Quality's Double-Edged Sword

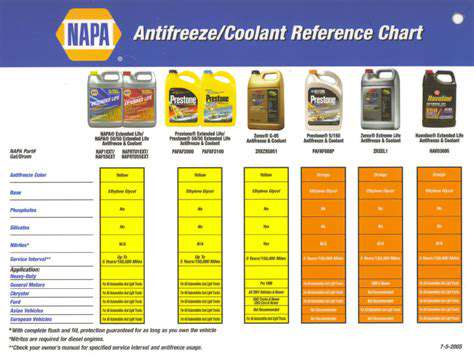

Not all fuels burn equally clean. The molecular composition of gasoline or diesel dramatically influences deposit formation. Premium fuels with robust detergent packages can actually clean existing deposits while preventing new ones, whereas bargain fuels often contain higher concentrations of deposit-forming compounds. The difference becomes apparent in engines running tens of thousands of miles - one maintains factory-spec performance while the other suffers from carbon-choked components.

Modern fuel formulations represent decades of petroleum engineering, yet many consumers remain unaware of the performance implications. The presence of certain additives can mean the difference between a throttle body that stays clean for 50,000 miles versus one requiring biannual cleaning. This explains why some vehicles develop carbon-related issues much sooner than others, even within the same model year.

Oxygen Starvation: Combustion's Silent Killer

Combustion systems operate on a simple principle - fuel needs oxygen to burn completely. When this relationship becomes unbalanced, carbon deposits gain the upper hand. Restricted air intake systems, malfunctioning EGR valves, or even high-altitude operation can create oxygen-deficient environments where carbon thrives. The deposits themselves then exacerbate the problem by further disrupting airflow, creating a vicious cycle of worsening combustion efficiency.

Turbocharged engines face particular challenges here. While forced induction systems deliver impressive power outputs, they also create localized hot spots where carbon deposits form more readily. This explains why some high-performance engines require more frequent carbon cleaning despite their technological sophistication.

Thermal Dynamics of Deposit Formation

Combustion chambers represent some of the most thermally stressful environments in mechanical systems. Temperature fluctuations directly influence deposit formation rates, with certain temperature bands actually accelerating the polymerization process. This explains why engines that frequently operate at partial load (like those in stop-and-go traffic) often show more severe carbon buildup than highway-driven counterparts.

The thermal story grows more complex when considering modern engine designs. Variable valve timing, cylinder deactivation, and other fuel-saving technologies create constantly changing thermal profiles. While these innovations improve efficiency, they also create new challenges for maintaining clean combustion chambers over the long term.

The Catalyst Conundrum

Catalytic converters represent one of the great environmental success stories of automotive engineering, but they also influence carbon deposition in unexpected ways. Certain catalytic formulations can actually promote the formation of specific carbon compounds under particular operating conditions. This creates a delicate balancing act for engineers - maximizing emissions control while minimizing deposit formation.

The situation becomes particularly interesting in direct injection engines, where fuel enters the combustion chamber without passing over intake valves. While this design improves efficiency, it also eliminates the cleaning effect of fuel washing over these components. The result? Intake valves that gradually accumulate stubborn carbon deposits unless specifically addressed through maintenance or specialized fuel additives.

Maintenance Matters More Than You Think

Modern vehicles have become remarkably resilient, often running well despite neglected maintenance. But this durability comes at a hidden cost - gradual carbon accumulation that subtly degrades performance over time. Following manufacturer-recommended service intervals isn't just about preventing catastrophic failures; it's about maintaining the precise combustion environment your engine was designed for.

Consider spark plugs as an example. While modern iridium plugs might last 100,000 miles, their gradual wear changes the characteristics of the spark. This seemingly minor change can initiate a cascade of effects that ultimately favors carbon deposition. Similar stories play out across dozens of engine systems, each contributing incrementally to the carbon problem.

The Importance of Regular Maintenance: Proactive Measures

Preventive Maintenance Saves Money

That old adage an ounce of prevention holds particular weight in mechanical systems. Early intervention doesn't just prevent major repairs - it preserves the engineered precision of modern machinery. Consider this: addressing minor carbon buildup might cost $200 today, but waiting until it causes misfires could lead to $2,000 in catalytic converter damage tomorrow.

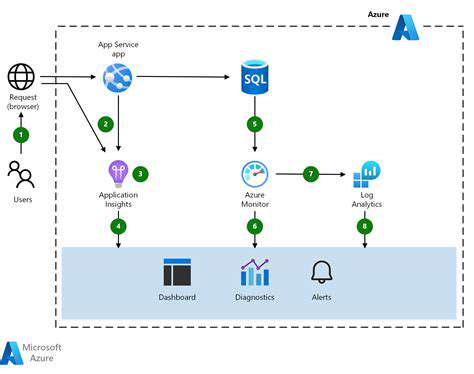

The financial calculus becomes even more compelling for fleet operators. Predictive maintenance technologies now allow managers to address issues before they cause downtime, transforming maintenance from a cost center to a profit-protection strategy. The data doesn't lie - well-maintained equipment consistently outperforms neglected counterparts in total cost of ownership calculations.

Reliability as Competitive Advantage

In industrial settings, equipment reliability translates directly to bottom-line results. A single hour of unplanned downtime can erase days of maintenance savings, making proactive care essential rather than optional. This explains why leading manufacturers invest heavily in condition-monitoring systems that track everything from vibration patterns to thermal signatures.

The benefits extend beyond mere uptime statistics. Consistently maintained equipment operates within its design parameters, producing more consistent output quality. In precision manufacturing applications, this reliability becomes a key differentiator in competitive markets.

Safety Through Diligence

Carbon-related issues aren't just performance concerns - they can become legitimate safety hazards. Excessive deposits in exhaust systems can create fire risks, while carbon-fouled sensors may provide dangerously inaccurate readings. Regular maintenance provides opportunities to identify and mitigate these risks before they escalate.

The safety implications extend beyond immediate hazards. Properly maintained equipment operates more predictably, reducing the likelihood of unexpected behaviors that could endanger operators. This becomes particularly critical in applications involving heavy machinery or high-energy systems.

The Hidden Costs of Downtime

While the direct costs of repairs are easily quantified, the ripple effects of unplanned downtime often prove more damaging. Missed deadlines, overtime wages, and lost customer goodwill all factor into the true cost of neglected maintenance. Smart operators view maintenance schedules as production planning tools rather than inconvenient interruptions.

The logistics of downtime also matter. Scheduled maintenance allows for proper parts staging and technician scheduling, while emergency repairs often incur premium costs for expedited shipping and overtime labor. The difference in total cost can easily reach 3-5x for equivalent repairs performed under emergency versus planned conditions.

American regulatory standards for nutritional products demonstrate an important principle - precise formulation prevents problems. The FDA's rigorous oversight of infant formula (requiring exact nutrient levels) mirrors the precision needed in fuel formulation to prevent carbon issues. Both cases show how small variations in composition can create significant downstream effects.

Cleaning the Throttle Body: A Necessary Evil?

The Stealthy Nature of Carbon Buildup

Throttle body deposits exemplify how gradual degradation escapes notice until reaching a critical threshold. Like cholesterol narrowing arteries, carbon accumulation subtly restricts airflow until the engine finally protests with rough idle or hesitation. This insidious progression explains why many drivers only address the issue after symptoms appear, rather than through preventive maintenance.

Cleaning as Performance Restoration

Proper throttle body cleaning often produces revelations - drivers frequently report their vehicle feels like new afterward. This dramatic improvement underscores how significantly even minor deposits can impact modern engine management systems. The precision of electronic throttle control means even thousandths of an inch of buildup can disrupt carefully calibrated airflow calculations.

The cleaning process itself has evolved considerably. Where mechanics once relied on carburetor cleaner and rags, modern approaches often incorporate specialized solvents and ultrasonic cleaning for thorough deposit removal. This reflects the increasing precision of throttle body designs and their critical role in engine management systems.

Symptom Recognition as Diagnostic Tool

Learning to interpret early warning signs represents a valuable skill for vehicle owners. That slight hesitation during gentle acceleration or the extra crank needed on cold mornings often precede more obvious symptoms. Modern OBD-II systems help by logging subtle changes in airflow and throttle position, but human observation still plays a crucial role in early detection.

The challenge lies in distinguishing carbon-related issues from other potential causes. Similar symptoms can stem from failing fuel pumps, clogged filters, or even weak ignition systems. This diagnostic complexity explains why professional assessment often proves valuable, despite the apparent simplicity of throttle body cleaning.

The Right Way to Clean

Effective throttle body cleaning requires more than just spraying cleaner. Proper technique involves:

- Complete removal for thorough access

- Using manufacturer-approved cleaners that won't damage sensitive coatings

- Careful attention to gasket surfaces and electrical connections

- Proper relearn procedures for electronic throttle bodies

Neglecting any of these steps can lead to incomplete cleaning or even create new issues. This explains why many professionals recommend throttle body service as part of scheduled maintenance rather than waiting for problems to develop.

Prevention Beats Cure

While cleaning addresses existing deposits, preventing their formation proves more effective long-term. Strategies include:

- Using Top Tier detergent gasoline

- Allowing periodic high-RPM operation to help burn off deposits

- Addressing any underlying issues causing rich mixtures

- Considering periodic fuel system cleaner treatments

These measures become particularly important for vehicles subjected to primarily short-trip driving, which creates ideal conditions for carbon accumulation. The combination of frequent cold starts and minimal high-temperature operation allows deposits to flourish.

Beyond the Throttle Body: Addressing Underlying Issues

Fuel System Forensics

Persistent carbon issues often point to deeper fuel system problems. A thorough diagnostic approach should examine:

- Fuel pressure regulation consistency

- Injector spray patterns and flow rates

- Pump voltage supply integrity

- Filter service history and restriction levels

Modern diagnostic tools allow technicians to monitor these parameters in real-time, revealing issues that might escape visual inspection. The difference between a temporary fix and permanent solution often lies in this comprehensive evaluation.

Breathing Matters: Air Intake Integrity

The air intake system's role in carbon management is frequently underestimated. Even minor leaks after the mass airflow sensor can create misleading readings that lead to improper fuel mixtures. Similarly, restricted intake paths force the engine to work harder, potentially creating localized hot spots that accelerate deposit formation.

Diagnostic strategies should include:

- Smoke testing for intake leaks

- Pressure testing for restrictions

- Thermal imaging for heat anomalies

- Volumetric efficiency calculations

These advanced techniques move beyond basic visual inspections to provide quantitative data about system health. The investment in thorough diagnostics often pays dividends through more accurate repairs and longer-lasting solutions.

The Electronic Factor

Modern engine management systems add layers of complexity to carbon-related issues. A single carbon-fouled sensor can trigger cascading adjustments across multiple systems, potentially masking the root cause. This explains why professional-grade scan tools have become essential for accurate diagnosis.

Key electronic considerations include:

- Sensor voltage and response times

- Adaptive learning values

- Fuel trim adjustments

- Component communication integrity

Addressing these factors systematically often reveals surprising connections between seemingly unrelated symptoms. The interplay between mechanical and electronic systems demands this comprehensive approach for effective carbon management.