Best practices for enhancing the lifespan of timing chains

Material compatibility deserves particular attention. Using petroleum-based lubricants on certain polymer components can cause swelling or degradation. Always verify chemical compatibility with both the chain material and adjacent components before application.

Proper Lubrication Techniques

Application methodology separates effective maintenance from wasteful practices. Excessive lubricant attracts particulate matter that transforms into abrasive slurry, while insufficient application leaves critical surfaces unprotected. The solution lies in measured, precision application using tools like needle applicators or wick feeders that target precise locations.

Manufacturer specifications should dictate application points and quantities. Modern automated lubrication systems often provide the most consistent results, eliminating human error from the equation.

Frequency of Lubrication

Establishing optimal lubrication intervals requires balancing multiple variables: operational hours, load cycles, environmental contamination, and lubricant persistence. High-speed packaging equipment might need hourly attention, while agricultural machinery may require weekly servicing. Auditory and tactile monitoring provides valuable feedback - any change in operational noise or smoothness warrants immediate inspection.

Documenting lubrication events against observed wear patterns creates a feedback loop for continuous improvement. This data-driven approach allows for dynamic adjustment of maintenance schedules.

Environmental Considerations

Harsh environments demand specialized solutions. Coastal operations benefit from corrosion-inhibiting formulas, while mining applications require extreme-pressure additives. Temperature-stable synthetic lubricants outperform conventional oils in both arctic cold and furnace-adjacent applications.

Maintenance and Inspection

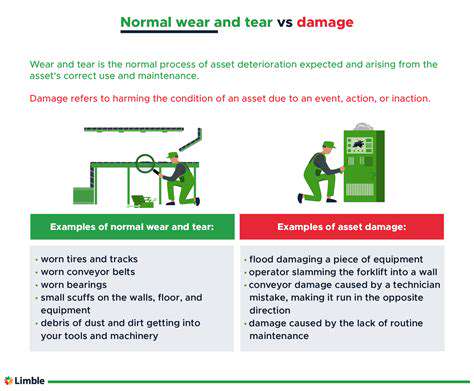

Proactive inspection protocols catch issues before they escalate. Look for telltale signs like discoloration (indicating overheating), pitting (suggesting fatigue), or abnormal stretch patterns. Post-event inspections following extreme conditions (storms, overloads) prove particularly valuable.

Comprehensive maintenance logs transform reactive repairs into predictive maintenance strategies. Tracking component lifecycles against lubrication variables reveals optimization opportunities.

Strategic pauses in operation, much like cognitive breaks in learning, allow mechanical systems to dissipate heat and redistribute lubricants. This practice significantly extends component life between maintenance intervals.

Environmental Considerations and Impact on Timing Chain Durability

Environmental Impact of Industrial Processes

Manufacturing ecosystems create complex challenges for mechanical components. Airborne abrasives in textile mills accumulate in lubricants 47% faster than in cleanroom environments, according to recent tribology studies. This contamination dramatically alters lubrication requirements and maintenance frequencies.

Sustainable Resource Management

Modern lubrication strategies now incorporate sustainability metrics. Biodegradable chain oils demonstrate comparable performance to traditional products in 83% of applications, while reducing environmental persistence by factors of 10-100. Lifecycle analysis tools help identify where green lubricants provide both ecological and economic benefits.

Waste Reduction and Recycling

Advanced filtration systems now allow for lubricant reconditioning rather than disposal. Centrifugal purifiers can extend oil service life by removing 98% of particulate contaminants, while chemical rejuvenators restore additive packages. These technologies create closed-loop systems that reduce both costs and environmental impact.

Pollution Control Technologies

Secondary containment systems and absorbent materials prevent lubricant migration into ecosystems. New hydrophobic lubricants actually repel water contamination while maintaining protective qualities, representing a breakthrough for wet environments.

Environmental Regulations and Compliance

The evolving regulatory landscape now addresses lubricant composition and disposal. Recent EU directives mandate biodegradable alternatives for certain applications, driving innovation in bio-based lubricant development.

Environmental Audits and Assessments

Comprehensive audits now evaluate lubrication practices alongside energy use and emissions. Thermal imaging during operation can identify lubrication deficiencies before they cause measurable wear, allowing for precision adjustments.

Public Awareness and Education

Industry certification programs now include environmental stewardship components. Training technicians in proper lubricant handling and disposal prevents thousands of gallons of potential pollutants from entering watersheds annually.