The importance of regular calibration for vehicle sensors

Understanding Vehicle Dimensions

Accurate vehicle measurements are crucial for various applications, from engineering designs to insurance calculations and even city planning. Understanding the different dimensions, such as length, width, height, wheelbase, and track, is essential to accurately represent a vehicle's physical characteristics. These measurements form the bedrock of many design and operational considerations, allowing for a precise representation of the vehicle's size and shape in various contexts.

Precise measurements of vehicle dimensions are fundamental to ensuring compatibility with infrastructure and other vehicles. Incorrect dimensions can lead to safety hazards and costly errors in manufacturing or design. Furthermore, accurate dimensions enable engineers to optimize vehicle performance, ensuring that the vehicle fits its intended purpose and functions efficiently.

Importance of Precise Vehicle Data

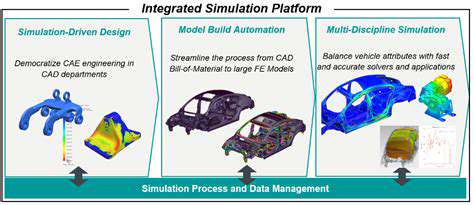

Precise vehicle data is critical for a multitude of applications. In the automotive industry, accurate specifications are vital for ensuring proper fitment of components, reliable operation, and meeting safety standards. This data is also essential for creating detailed design blueprints, engineering models, and performance simulations.

Accurate vehicle data is invaluable in accident reconstruction, allowing investigators to understand the collision forces and circumstances. Insurance companies also rely on precise measurements to assess damages and determine appropriate payouts. The proper data is essential for insurance companies to calculate the level of coverage needed and the expected payout.

Verification Methods and Tools

Several methods and tools are used to verify and obtain accurate vehicle dimensions. These methods range from traditional surveying techniques using measuring tapes and rulers to advanced 3D scanning technologies. Laser scanning systems provide highly detailed and precise data sets, capturing the vehicle's shape and contours with remarkable accuracy.

Specialized software programs analyze the data collected by these methods, extracting precise measurements and generating comprehensive reports. These reports are essential for various applications, from engineering design to insurance claims. Using these verified measurements, manufacturers and engineers can optimize manufacturing processes, reducing waste and improving efficiency.

Applications Across Industries

The need for accurate vehicle dimensions extends far beyond the automotive industry. City planners use these measurements to design roadways, parking lots, and public transportation systems that accommodate various vehicle types. Traffic engineers rely on precise data to model traffic flow and optimize traffic signal timings.

Accurate vehicle data is essential for ensuring the safety and efficiency of transportation systems. Furthermore, regulatory bodies use these dimensions to enforce vehicle standards and ensure compliance. This broad application demonstrates the significance of precise vehicle measurements across a wide range of industries and professions.

Accurate vehicle dimensions are critical for the smooth operation of many areas of our lives, from manufacturing and engineering to city planning and safety protocols. Understanding and verifying these dimensions are crucial for a variety of applications and considerations.

Beyond the Basics: The Impact of Inaccurate Sensor Readings

Calibration and Maintenance

Regular calibration and maintenance are crucial for ensuring accurate sensor readings. Calibration involves comparing the sensor's output to a known standard, identifying any discrepancies, and adjusting the sensor's parameters to achieve accurate measurements. This process helps maintain the sensor's precision and reliability over time, preventing errors that can accumulate and lead to significant inaccuracies in subsequent data collection. Proper maintenance, including cleaning, lubrication, and replacing worn components, is equally important for optimal performance.

Ignoring these crucial steps can lead to systematic errors in the data, which might be difficult to detect and correct. Furthermore, inadequate maintenance can shorten the lifespan of the sensor, necessitating costly replacements and potentially disrupting ongoing projects. A well-maintained sensor is a reliable sensor, ensuring the integrity of your data and its subsequent analysis.

Environmental Factors

Environmental conditions can significantly influence sensor readings. Temperature fluctuations, humidity levels, and pressure variations can all impact the accuracy of measurements. For example, a temperature sensor might produce inaccurate readings if exposed to extreme temperatures or significant temperature gradients. Understanding these potential influences and controlling them through appropriate environmental controls or sensor placement is essential for achieving reliable results.

Properly selecting sensors designed to withstand specific environmental conditions is also essential. Sensors designed for harsh environments, like those found in industrial settings, are often built with rugged materials and protective casings to withstand various environmental pressures. Understanding the specific environment where the sensor will operate is key to selecting the right sensor for the job.

Sensor Type and Application

The choice of sensor type and its appropriate application directly impacts the accuracy of measurements. Different sensors are designed for different measurement tasks, and using a sensor inappropriately can lead to significant errors. For example, using a pressure sensor designed for high-pressure environments in a low-pressure application will likely result in inaccurate readings. A thorough understanding of the intended application and the characteristics of various sensor types is essential to ensure accurate data collection.

Data Acquisition and Processing

The methods used for data acquisition and processing can also contribute to inaccurate readings. Using inappropriate sampling rates or inadequate data filtering techniques can introduce noise and errors into the collected data. Employing advanced signal processing techniques can help mitigate these issues and improve data accuracy. Choosing the right tools and techniques for data acquisition and processing is crucial for ensuring the reliability of the data.

Signal Interference and Noise

External factors, such as electromagnetic interference (EMI) and other forms of noise, can corrupt sensor signals and lead to inaccurate readings. EMI, for instance, can significantly affect the accuracy of electrical sensors. Implementing shielding measures and employing appropriate filtering techniques can help mitigate these issues. Understanding the potential sources of interference and implementing appropriate countermeasures is crucial for obtaining accurate measurements.

Data Validation and Error Analysis

A critical step in ensuring reliable data is thorough data validation and error analysis. This involves examining the collected data for patterns, inconsistencies, and outliers, which could indicate errors in sensor readings. Validating the data collected against known standards or expected values can help identify and correct potential inaccuracies. Implementing robust data validation procedures ensures confidence in the collected data and enables better decision-making based on the information obtained.

Assess layout and fixtures for compact bathroom optimization.