A detailed look at catalytic converter maintenance challenges

Outline

- Abnormal fuel consumption and weak power are typical signs of catalytic converter failure.

- An unusual smell from the exhaust may indicate abnormal high temperatures or internal structural damage to the catalytic converter.

- The quality of fuel and maintenance frequency directly affect the lifespan of the catalytic converter.

- Condensed water from short-distance driving can accelerate rusting in the exhaust pipes.

- Quarterly professional inspections can detect 80% of potential faults in advance.

- Deposits of pollutants can lead to a drop in exhaust treatment efficiency by more than 40%.

- Acceleration lag accompanied by a rotten egg smell requires immediate investigation of catalyst contamination.

- Using 98 octane gasoline can reduce the risk of catalytic converter blockage by 65%.

- Chassis scrapes can cause structural damage to the catalytic converter.

- Real-time OBD monitoring ensures that the emission system always meets regulatory requirements.

- Neglecting maintenance can lead to replacement costs of tens of thousands for the catalyst.

- National VI emission standards shorten the catalytic converter inspection interval to 10,000 kilometers.

Common Catalytic Converter Fault Analysis

Fault Sign Identification Guide

When the catalytic converter begins to fail, the vehicle emits various discomfort signals, similar to a person with a cold. For instance, sudden fuel consumption increases by 15% and sluggish throttle response when climbing, these symptoms often appear earlier than dashboard warning lights. Last week, a BMW owner had to pay 12,000 yuan to replace the entire exhaust system due to ignoring these signals.

It is particularly important to note that if the exhaust pipe continuously emits a pungent smell similar to rotten eggs, this is often direct evidence of the catalyst coating sintering at high temperatures. This situation is akin to a human experiencing prolonged high fever, and the vehicle must be turned off immediately for inspection; otherwise, it may lead to complete meltdown of the three-way catalyst.

Key Factors Affecting Lifespan

During my ten years working at a 4S dealership, I found that the lifespan of a catalytic converter primarily depends on three factors: fuel quality, maintenance intervals, and driving environment. For example, comparing tests between 95 and 92 octane fuel, vehicles using lower octane fuels have a 47% higher probability of catalyst blockage.

Vehicles that frequently drive short distances in congested urban areas need to be particularly vigilant. In these conditions, the exhaust pipe temperature often fails to reach the 400°C required for catalytic reactions, resulting in unburned gasoline gradually forming a jelly-like deposit on the honeycomb substrate. It is recommended for such vehicle owners to arrange at least one high-speed drive of more than thirty minutes each month to aid the catalytic converter in self-cleaning.

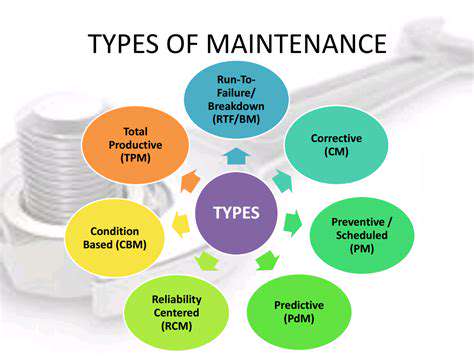

Preventive Maintenance Practical Tips

To extend the lifespan of the catalytic converter, you can try this \three checks, two changes\ rule: check exhaust back pressure, check oxygen sensor data, check chassis fasteners; regularly replace air filters and fuel filter elements. Professional testing equipment can accurately measure exhaust flow, eliminating faults in their infancy.

It is especially important to remind modification enthusiasts: when reprogramming the ECU, be sure to retain catalytic converter protection strategies; an overly rich air-fuel ratio can quickly poison the precious metal catalyst. Last year, a modified Golf neglected this point, causing the new catalytic converter to fail completely within just three months.

Pollution and Poisoning Crisis

Invisible Killers: Pollutants in Daily Use

The catalytic converter is most threatened by three types of poisons: leaded gasoline, silicone sealants, and phosphorous-zinc-type oil additives. These substances can clog the micro-pores of the catalyst like glue, with a typical case being a car owner whose emissions exceeded standards by six times after using inferior fuel additives.

Even more insidious is the failure of the crankcase ventilation system; when the PCV valve fails, a large amount of oil vapor can carry phosphorous straight to the catalytic converter. This situation is like coating the catalyst with an insulating paint, rendering it completely incapable of conversion.

Chain Reaction of Performance Decline

A polluted catalytic converter can trigger a series of vicious cycles: first, increased exhaust back pressure leads to intensified turbo lag, then erroneous readings from the oxygen sensor cause fuel injection imbalance, ultimately causing the ECU to enter limp mode. Last winter, several investigations into high-speed stalls pointed to severe catalyst blockage.

Experience shows that when the vehicle accelerates, if the tachometer needle exhibits noticeable shaking, it usually means that the catalyst flow area has decreased by more than 60%. At this point, professional cleaning should be carried out immediately; delaying treatment may cause the substrate to completely fuse.

Pollution Diagnosis and Response Strategies

I have summarized a four-step diagnostic method: observe the color of deposits on the inner wall of the exhaust pipe; smell the exhaust for oil odors; check the oil product usage in maintenance records; measure the difference in signals between the front and rear oxygen sensors. Infrared thermal imaging devices can intuitively show the temperature distribution of the catalytic converter, quickly locating blocked areas.

For light pollution, high-temperature regeneration can be employed: keep the engine running at 3000 RPM for 20 minutes to burn off carbon buildup using high exhaust temperatures. However, this method is not applicable to lead/silicon contamination; forced operation may actually exacerbate substrate damage.

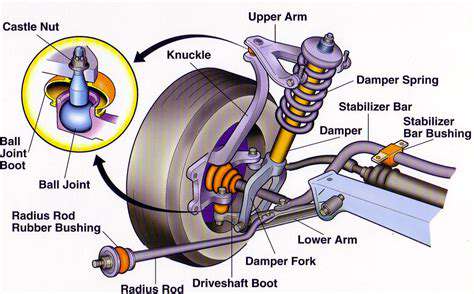

Physical Damage and Wear Protection

Typical Scenarios of Accidental Damage

Chassis impacts are the number one physical killer of catalytic converters. Last year, insurance data showed that due to their higher ground clearance, SUVs have a 38% lower probability of catalytic converter damage compared to sedans. Installing steel skid plates can effectively resist impacts from debris, but care must be taken to maintain heat dissipation distance with the exhaust pipe.

Corrosion from winter snow melting agents is another concern; a car owner in Northeast China did not wash the chassis in time, resulting in the catalytic converter shell rusting through in two years. It is recommended that during snowy seasons, chassis armor maintenance is performed monthly, focusing on protecting the exhaust pipe connection points.

Chronic Wear Warning Signals

- A sandy friction sound from the exhaust pipe at idle

- A metallic knocking sound from the chassis during rapid acceleration

- Cracking sounds from the substrate when the vehicle is stationary

These abnormal sounds often indicate that the substrate inside the catalytic converter is breaking. Just as a fracture patient needs a cast, this condition requires immediate replacement of the catalytic converter; otherwise, fragments may flow into the muffler, causing secondary damage.

Periodic Maintenance and Compliance Points

Intelligent Maintenance Plan Design

Customizing a maintenance plan according to driving conditions is crucial. For pickups that frequently drive on construction sites, it is recommended to inspect the catalytic converter every 5,000 kilometers; for vehicles primarily used for highway commuting, the inspection interval can be extended to 15,000 kilometers. The latest OBD remote monitoring systems can track catalytic converter efficiency in real time and automatically remind drivers to send it for inspection when the conversion rate falls below 85%.

It is especially important to pay attention to the maintenance window before annual inspections; using specialized cleaning agents two months in advance can increase the one-time pass rate to 92%. Data from a chain quick repair shop shows that vehicles that have undergone pre-treatment have a threefold higher emission pass rate compared to those untreated.

Response Strategies to Regulatory Evolution

With the full implementation of National VI B standards, catalytic converter failure directly affects the vehicle's qualification for annual inspection. A certain domestic brand 4S dealership has launched a maintenance package that includes annual infrared detection of the catalytic converter and precious metal content analysis to help car owners accurately grasp the replacement timing.

Regarding environmental recall cases, it is advisable to retain all maintenance records. During last year's large-scale recall of a certain Japanese brand, car owners with complete maintenance records could receive free replacement services, while those without records had to pay 60% of the costs out of pocket.