ABS Sensor Replacement: Braking Safety

Understanding the Function of ABS Sensors

Understanding the Fundamental Role of ABS Sensors

Anti-lock braking systems (ABS) are crucial for vehicle safety, preventing wheels from locking up during sudden braking maneuvers. ABS sensors play a vital role in this process by constantly monitoring wheel speed. These sensors are critical components of the braking system, ensuring the driver maintains control of the vehicle and avoids skidding in challenging situations. Their precise and reliable data transmission is essential for the ABS system's functionality.

Accurate wheel speed information allows the ABS control module to modulate brake pressure, preventing the wheels from locking. This precise control is what enables the driver to maintain steering control during emergency braking scenarios, significantly enhancing safety and reducing the risk of accidents.

How ABS Sensors Work

ABS sensors typically utilize a magnetic field-based technology that reacts to the rotating wheel. As the wheel rotates, the magnetic field changes, and this change is detected by the sensor. This detection triggers a signal to the ABS control module, providing real-time information on the wheel speed. Different types of ABS sensors may use varying technologies, but the fundamental principle of measuring wheel speed remains consistent.

The Importance of Accurate Signal Transmission

The accuracy of the signal transmitted by the ABS sensor is paramount. Any inaccuracies in the signal can lead to the ABS system malfunctioning, potentially resulting in a loss of braking control. A faulty sensor can cause the ABS system to misinterpret wheel speed, leading to improper brake application and reduced safety.

Potential Issues with ABS Sensors

ABS sensors, like any other automotive component, can experience malfunctions over time. These issues can stem from various factors, including corrosion, physical damage, or internal component failures. Detecting these issues early is crucial to prevent compromised braking performance and potential accidents.

Furthermore, external factors such as debris or moisture can impede the sensor's ability to accurately measure wheel speed. Regular inspections and maintenance can help identify and address these potential problems before they lead to serious consequences.

The Relationship Between ABS Sensors and Braking Performance

The performance of the ABS system is directly linked to the functionality of the ABS sensors. If the ABS sensors are faulty or malfunctioning, the ABS system will not function correctly. This can lead to a significant reduction in braking performance, potentially making it more difficult for the driver to stop the vehicle safely. Understanding this relationship between the two is vital to maintaining safe braking operation and reducing the risk of accidents.

Troubleshooting ABS Sensor Issues

Troubleshooting ABS sensor problems often involves a combination of diagnostic tools and procedures. A trained technician can use specialized diagnostic equipment to identify specific sensor problems, such as faulty signals or inconsistent readings. This process can pinpoint the exact source of the issue, allowing for targeted repairs and minimizing downtime.

The Impact of ABS Sensor Failure on Vehicle Safety

A failed ABS sensor can significantly compromise vehicle safety during critical braking events. The lack of accurate wheel speed feedback to the ABS control module can lead to the wheels locking up, causing the vehicle to skid. This loss of control significantly increases the risk of accidents, making ABS sensor maintenance a critical aspect of vehicle safety. Consequently, regular inspections and prompt replacement of faulty sensors are essential to prevent accidents and maintain optimal braking performance.

The Importance of Timely ABS Sensor Replacement

Understanding ABS Sensor Function

Anti-lock Braking System (ABS) sensors are crucial components in modern vehicles, playing a vital role in maintaining vehicle control during emergency braking situations. These sensors constantly monitor wheel speed and send signals to the ABS control module. This real-time feedback allows the system to modulate brake pressure, preventing the wheels from locking up. Without functioning ABS sensors, the driver loses this critical safety feature, potentially leading to loss of control and increased stopping distances.

Understanding how these sensors work is key to comprehending their importance in maintaining vehicle safety. They use a variety of technologies, often involving the detection of magnetic fields or other physical changes in the wheel's rotation, to accurately measure speed. This data is then processed by the ABS control module, enabling the system to react precisely and effectively.

Identifying Signs of Failing ABS Sensors

Recognizing the early warning signs of failing ABS sensors is vital for maintaining safe driving practices. A common indication is a warning light illuminating on the dashboard, often accompanied by an audible alert. Another sign is a pulsating or uneven braking sensation, as the ABS system struggles to properly regulate brake pressure. These symptoms, while not always definitive, strongly suggest a potential problem with the ABS sensors and warrant prompt inspection and repair.

Furthermore, erratic brake response, such as the feeling of the brakes grabbing or failing to release properly, can also be an indicator of ABS sensor issues. It's essential to pay attention to any unusual braking behavior, as it could signal a potentially serious safety concern. Ignoring these warning signs can lead to compromised braking performance and increase the risk of accidents.

The Impact of Delayed ABS Sensor Replacement

Delaying the replacement of faulty ABS sensors can have significant consequences for vehicle safety. The system's ability to regulate brake pressure diminishes as sensors malfunction, potentially leading to longer braking distances in emergency situations. This reduced braking performance can be particularly dangerous in challenging driving conditions such as wet roads or high-speed maneuvers.

Moreover, a compromised ABS system can lead to a loss of vehicle control, especially during sudden braking events. This could result in accidents, injuries, and costly repairs. Addressing ABS sensor issues promptly is not just a matter of maintaining the vehicle's functionality; it's a crucial step in ensuring the safety of the driver and other road users.

Potential Costs Associated with Neglect

Neglecting faulty ABS sensors can lead to a cascade of escalating costs. Beyond the cost of the replacement sensors themselves, there's the potential for further damage to other critical braking components. The longer the issue is left unresolved, the greater the risk of significant brake system damage. This can necessitate costly repairs or even complete brake system replacements.

Furthermore, the increased risk of accidents due to compromised braking performance can result in significant financial burdens, including repair costs for the vehicle itself, medical expenses for those involved, and potential legal fees. These costs far outweigh the relatively modest expense of timely ABS sensor replacement.

The Importance of Professional Inspection

Diagnosing ABS sensor issues requires specialized tools and expertise. Attempting to diagnose and repair these components without proper training can lead to further complications. Professional mechanics are equipped with the knowledge and equipment to accurately assess the condition of the ABS sensors and determine the most effective course of action.

Professional inspection ensures that the problem is correctly identified, preventing unnecessary repairs and ensuring that the ABS system functions optimally. This proactive approach safeguards both the vehicle's performance and the driver's safety, making it a worthwhile investment.

Preventive Maintenance Strategies

Implementing preventive maintenance strategies can help extend the lifespan of ABS sensors and minimize the risk of costly repairs. Regular vehicle inspections, particularly focusing on the braking system, are essential. This includes checking for any signs of wear, damage, or unusual noises related to the ABS system, ensuring that potential problems are identified and addressed promptly.

Maintaining proper tire pressure and ensuring that the brakes are adequately lubricated are also crucial elements of preventive maintenance. These actions can help to maintain optimal performance and extend the lifespan of all components, including the ABS sensors. Ultimately, proactive maintenance contributes to both safety and cost-effectiveness in the long run.

Conclusion

In conclusion, timely ABS sensor replacement is not just a matter of vehicle maintenance; it's a critical safety concern. Understanding the function of these sensors, recognizing the signs of failure, and understanding the potential costs of delay are essential for responsible vehicle ownership. By prioritizing professional inspection and preventive maintenance, drivers can ensure the integrity of their braking system and contribute to the overall safety of themselves and other road users.

Diagnosis and Replacement Procedures

Understanding ABS Sensor Malfunctions

ABS sensors, crucial components of the anti-lock braking system (ABS), monitor wheel speed. A malfunctioning ABS sensor can lead to a range of issues, from erratic braking performance to the ABS system completely failing to engage. Understanding the symptoms of a faulty sensor is the first step in ensuring safe and reliable braking. Early diagnosis can prevent more serious problems and costly repairs down the road.

Various factors can contribute to ABS sensor failure, including corrosion, physical damage, or internal electrical issues. These factors can lead to inaccurate speed readings, causing the ABS system to malfunction. Ignoring these signs can lead to diminished braking effectiveness and potentially dangerous driving situations.

Identifying Symptoms of a Failing ABS Sensor

Recognizing the symptoms of a failing ABS sensor is vital for prompt diagnosis and repair. Common symptoms include the illuminated ABS warning light on your dashboard, a pulsating or spongy brake pedal, or a complete lack of ABS function during braking. These symptoms can vary depending on the specific vehicle and the severity of the sensor failure.

Additionally, you might experience a noticeable decrease in braking responsiveness or a strange, almost vibrating sensation when braking. Paying close attention to these subtle cues can be the key to preventing a more significant braking system issue and maintaining safe driving practices.

Diagnostic Tools and Procedures

Properly diagnosing an ABS sensor issue necessitates the use of appropriate diagnostic tools. A scan tool, capable of reading ABS system codes, can pinpoint the specific sensor malfunction. These codes provide crucial information about the problem and help direct the repair process.

Visual inspection of the sensor's connections and surrounding components is also essential to identify any obvious physical damage or corrosion. Thorough inspection can save time and money by quickly eliminating potential causes and directing your attention to the actual problem.

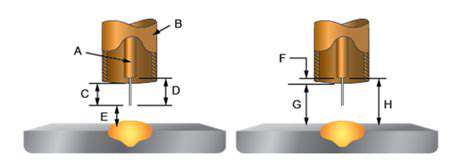

Locating the ABS Sensor

Precise location of the ABS sensor is crucial for successful replacement. Sensor placement varies depending on the vehicle make and model. Consult your vehicle's repair manual for specific instructions on locating the ABS sensor on your vehicle. The location typically involves accessing components beneath the vehicle or within the wheel well. Carefully following the repair manual's instructions is essential to avoid causing further damage.

Understanding the precise location of the sensor helps in planning the replacement process and ensuring proper access during the repair procedure.

Preparing for ABS Sensor Replacement

Preparing for ABS sensor replacement involves gathering necessary tools, parts, and safety equipment. Ensure you have the correct replacement sensor for your vehicle make and model. Gather any necessary tools, such as wrenches, sockets, and screwdrivers, and safety gear like gloves and eye protection.

Proper preparation minimizes potential complications during the replacement process and ensures a smooth, efficient repair. Having all the required materials on hand streamlines the procedure and helps prevent delays.

Replacing the ABS Sensor

The replacement procedure involves disconnecting the old sensor, removing it from its housing, and installing the new sensor. Carefully follow the manufacturer's instructions for the specific vehicle model to ensure a correct installation. Connecting the new sensor and verifying its function is crucial for the ABS system to operate correctly.

Ensure proper torque specifications when tightening bolts and connections during the replacement process. Incorrect torque can lead to future issues and potentially compromise the integrity of the braking system.

Testing and Verification

After replacing the ABS sensor, thorough testing is necessary to ensure proper functionality. Using a scan tool, verify that the ABS system codes are cleared and that the ABS warning light is no longer illuminated. Perform a series of braking tests to confirm that the ABS system is functioning correctly, and that braking is responsive and consistent. Thorough testing is essential to guarantee the safety and reliability of the repaired braking system.

Confirming the ABS system's proper operation after sensor replacement is crucial for maintaining safe driving practices and preventing future issues. This step ensures the replacement was successful and that the vehicle is ready for safe operation.