Benefits of upgrading to lightweight wheels for improved efficiency

Consider software development as an example. Bloated codebases filled with unused libraries and redundant data structures act like digital anchors. Through careful pruning and optimization, developers can transform sluggish applications into nimble, responsive tools. This philosophy extends beyond initial development - maintaining this lean approach ensures systems remain adaptable and manageable throughout their lifecycle.

Targeted Weight Reduction Strategies

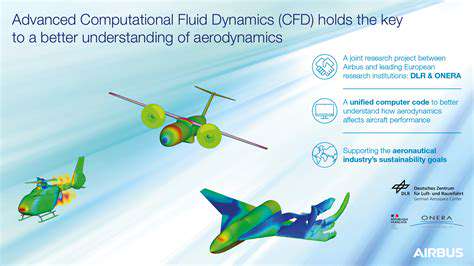

Successful weight reduction demands context-specific approaches. Aerospace engineers employ sophisticated modeling techniques to shave grams without compromising safety. They might use finite element analysis to identify structural redundancies or experiment with advanced composite materials that offer strength without excessive mass.

In the digital realm, developers utilize profiling tools that act like X-ray vision for code efficiency. These tools reveal which processes consume disproportionate resources, allowing for surgical optimization. The most impactful improvements often come from algorithm optimization rather than brute-force hardware upgrades. This precision approach yields maximum performance gains with minimal disruption.

Benefits and Impact of Weight Reduction

The ripple effects of weight optimization extend far beyond initial expectations. Transportation systems demonstrate this clearly - every kilogram removed translates to measurable fuel savings and reduced environmental impact. Digital platforms benefit similarly, where streamlined code leads to faster load times and happier users.

This performance transformation creates competitive advantages that resonate throughout entire industries. Companies that master these optimization techniques consistently outperform their peers in both product quality and operational efficiency. The ongoing pursuit of leaner solutions has become a hallmark of successful modern enterprises.

Improved Acceleration and Handling Characteristics

Enhanced Responsiveness

Lightweight component upgrades fundamentally change a vehicle's personality. The physics are undeniable - less mass means quicker reactions to driver inputs. This transformation becomes most apparent during dynamic driving situations where milliseconds matter. The difference between ordinary and exceptional handling often comes down to these careful weight reductions.

Drivers immediately notice the improved feedback through the steering wheel and pedals. The vehicle feels more connected to the road, responding to subtle inputs with precision that heavier counterparts simply can't match.

Reduced Fuel Consumption

Physics dictates that moving less mass requires less energy. This principle manifests in real-world fuel savings that accumulate significantly over a vehicle's lifespan. The engine operates more efficiently when not burdened by unnecessary weight, particularly during acceleration and hill climbing.

Improved Handling and Steering

The benefits of reduced mass become most apparent in the vehicle's dynamic behavior. Corners that previously felt challenging become effortless, with the car maintaining composure where heavier vehicles might struggle. This handling improvement isn't just about performance - it enhances safety in emergency maneuvers.

Enhanced Stability

High-speed stability improves dramatically with proper weight reduction. The vehicle feels planted and confident, resisting the floatiness that often plagues heavier designs. This characteristic proves particularly valuable during highway driving or when encountering crosswinds.

Enhanced Braking Performance

Stopping distances shorten noticeably with reduced mass. The brakes don't need to overcome as much momentum, resulting in more immediate deceleration. This improvement could mean the difference between avoiding an obstacle or not in emergency situations.

Longer Lifespan of Components

Mechanical components experience less stress when not constantly moving excessive weight. Suspension components last longer, bearings wear more slowly, and the entire drivetrain benefits from reduced operational loads.

Enhanced Ride Comfort

Paradoxically, reducing weight often improves ride quality. The suspension can respond more effectively to road imperfections when not burdened by excessive mass. This results in better isolation from road harshness without sacrificing handling precision.

Cost Considerations and Return on Investment

Initial Investment Costs

Every significant project begins with financial commitments that extend beyond the obvious purchase price. Smart investors account for the hidden expenses that often derail poorly planned projects - specialized tools, compliance certifications, and unexpected installation challenges. These factors frequently determine whether an investment succeeds or becomes a financial burden.

Detailed cost analysis should examine every phase of implementation. Transportation logistics, site preparation, and professional services often represent substantial portions of the total investment that novices frequently underestimate.

Operational Expenses

The true test of any investment comes during daily operation. Maintenance schedules, energy requirements, and staffing needs create ongoing financial commitments that must align with projected revenues. Regular operational audits often reveal surprising opportunities for efficiency improvements that can significantly impact long-term profitability.

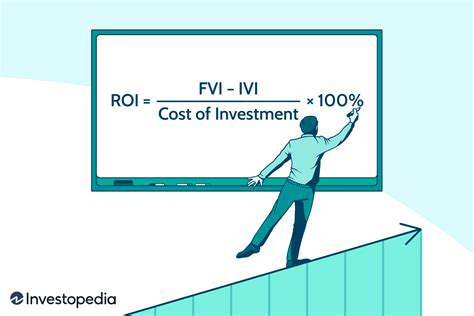

Return on Investment (ROI) Calculation

Sophisticated ROI analysis considers more than simple payback periods. Market volatility, competitive pressures, and technological obsolescence all factor into accurate projections. The most successful investors build multiple scenarios that account for various market conditions rather than relying on optimistic single-outcome projections.

Contingency Planning

Financial resilience separates thriving enterprises from struggling ones. Establishing reserve funds for equipment failures, supply chain disruptions, or regulatory changes provides crucial flexibility. This financial cushion often determines whether a business survives unexpected challenges.

Tax Implications

Tax strategy should inform every significant investment decision. Different jurisdictions offer varying incentives for equipment purchases, research initiatives, or energy-efficient upgrades. Strategic tax planning can transform marginal projects into highly profitable ventures when executed properly.