Comprehensive guide to balancing performance and fuel economy

Aerodynamics and Vehicle Weight: Subtle but Crucial Factors

Aerodynamic Design Considerations

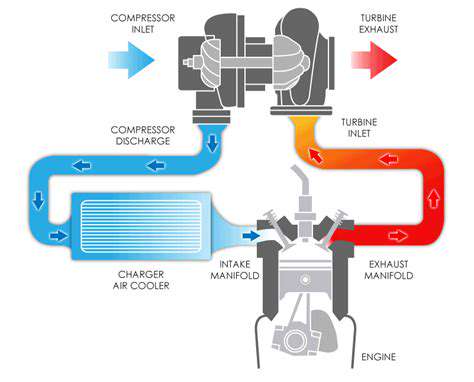

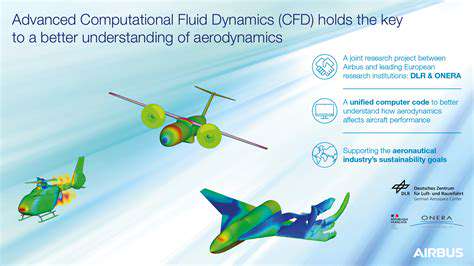

Aerodynamics plays a critical role in vehicle performance, influencing everything from fuel efficiency to handling characteristics. A streamlined design minimizes air resistance, reducing the power required to propel the vehicle at a given speed. This translates directly to improved fuel economy, reduced emissions, and ultimately, a more sustainable transportation option. Careful consideration of airflow patterns, such as minimizing turbulence and maximizing laminar flow, is paramount in optimizing aerodynamic efficiency.

The shape of the vehicle body, including the front end, roofline, and rear end, significantly impacts its aerodynamic profile. Engineers meticulously analyze these shapes to identify areas where airflow can be manipulated to reduce drag. This process often involves computational fluid dynamics (CFD) simulations to model airflow around the vehicle and identify potential improvements.

The Impact of Weight on Performance

Vehicle weight is a fundamental factor influencing performance across various aspects. A lighter vehicle requires less energy to accelerate and decelerate, leading to better fuel economy and quicker response times. Every extra pound adds to the overall inertia, hindering acceleration and increasing braking distances. Reducing weight is a key strategy in enhancing performance and fuel efficiency.

Material selection is crucial in minimizing weight. Advanced materials like carbon fiber composites and aluminum alloys are increasingly used to reduce vehicle mass while maintaining structural integrity. Engineers employ sophisticated methods to identify weight-saving opportunities without compromising safety standards, leading to more efficient and responsive vehicles.

Weight Reduction Strategies

Weight reduction strategies extend beyond material selection to encompass the design and manufacturing processes. Optimizing the vehicle's structural components, eliminating unnecessary parts, and utilizing lightweight manufacturing techniques are integral parts of this process. This involves careful consideration of the structural elements to ensure that the vehicle's strength and safety are not compromised by weight reduction efforts.

Careful consideration of the vehicle's interior design and materials is essential. Lightweight materials for seats, dashboards, and other interior components contribute to the overall reduction in weight. The selection of components with optimal strength-to-weight ratios plays a crucial role in achieving the desired balance between vehicle performance and structural integrity.

The Interplay Between Aerodynamics and Weight

The relationship between aerodynamics and vehicle weight is not simply additive, but rather complex and synergistic. A streamlined design can help mitigate the negative impact of weight on fuel economy. A lightweight vehicle can further enhance the benefits of a well-designed aerodynamic profile. Optimizing both simultaneously leads to a significant improvement in overall vehicle performance.

For example, a heavier vehicle with poor aerodynamics will struggle to achieve high fuel efficiency. Conversely, a lightweight vehicle with a well-designed aerodynamic profile will be far more fuel-efficient. The interplay between these two crucial aspects is a key focus in modern vehicle design.

The Importance of Balancing Design Elements

Balancing aerodynamics and vehicle weight is not a simple trade-off, but rather a complex optimization problem. Engineers must consider numerous factors simultaneously to achieve the optimal design. For example, a very lightweight vehicle might sacrifice some structural rigidity, potentially compromising safety and passenger comfort. Conversely, a highly aerodynamic design might lead to a higher vehicle weight. Experienced engineers evaluate and balance these competing factors to arrive at a comprehensive and balanced solution.

Thorough testing and simulations are essential to validate the design and ensure that the benefits of both aerodynamics and weight reduction translate into tangible improvements in performance and fuel efficiency. This rigorous validation process is critical for delivering a vehicle that meets both performance and safety requirements.