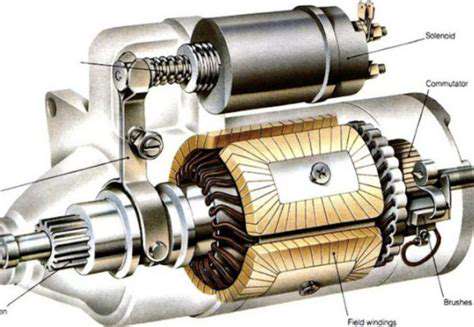

How proper gearing improves torque in heavy duty vehicles

Mastering this balance allows designers to create systems that deliver exactly what operators need, whether that's brute strength or rapid movement.

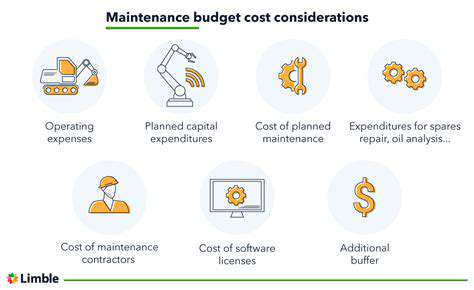

Load Capacity and Gear Strength

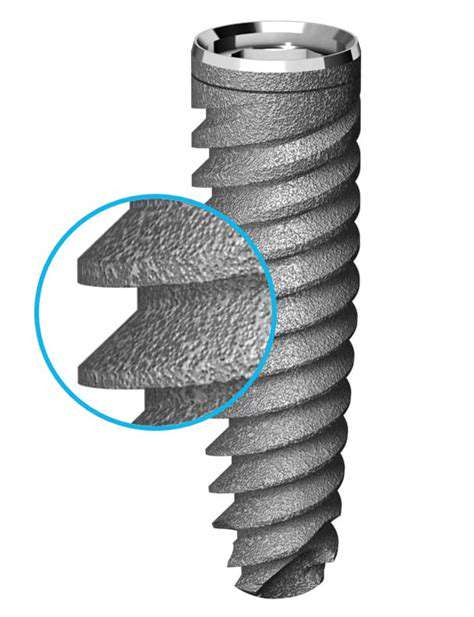

Heavier loads demand tougher gears - there's no way around this reality. Material selection and precision engineering become critical when designing for demanding applications. Cutting corners here leads to premature failures and costly downtime.

The geometry of gear teeth matters just as much as the metal they're made from. Both factors must align with the expected workload to ensure reliable, long-lasting performance.

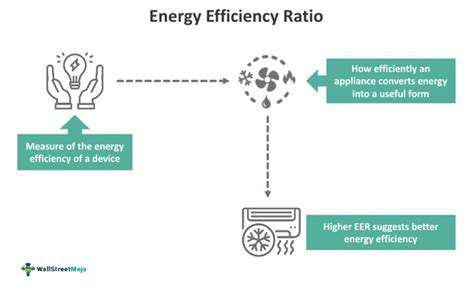

Impact of Gear Ratio on Efficiency

Proper ratio selection can dramatically reduce energy waste in mechanical systems. The wrong choice leads to unnecessary friction and power loss. Smart engineers analyze all variables to find the most efficient configuration for each unique situation.

This optimization process often reveals surprising opportunities to improve performance while reducing operating costs.

Considerations for High-Speed Applications

When speed takes priority, gear materials and designs face extraordinary challenges. The stresses of rapid rotation demand exceptional precision in manufacturing. Even microscopic imperfections can cause major problems at high RPMs.

Vibration control becomes paramount in these environments. The difference between success and failure often comes down to how well the design handles these dynamic forces.

Selecting Ratios for Low-Torque Applications

Applications emphasizing speed over power benefit from lower gear ratios. Conveyor systems and automated equipment often fall into this category. The trick lies in providing just enough torque without sacrificing the desired velocity.

Getting this balance wrong leads to either insufficient power or wasted energy - both costly mistakes in industrial settings.

Analyzing System Dynamics and Feedback

Truly exceptional gear systems account for how components interact during operation. Advanced simulations and real-world testing reveal insights that static analysis misses. This dynamic understanding allows for fine-tuning that elevates performance.

Continuous monitoring provides valuable data for ongoing improvements, helping systems evolve to meet changing demands.

Measure space for optimal TV wall design integration.

Advanced Gearing Technologies for Enhanced Performance

Improved Efficiency and Reduced Wear

Cutting-edge gear technology brings remarkable efficiency gains across industries. Modern designs coupled with innovative materials minimize energy loss through friction. The payoff comes in reduced operating costs and extended equipment lifecycles.

Specialized lubricants and surface treatments push these benefits even further. These advancements create smoother operation while dramatically decreasing maintenance requirements - a win-win for any operation.

Enhanced Load-Bearing Capacity

Today's gear materials laugh in the face of loads that would destroy older designs. Heat-treated alloys and precision manufacturing techniques allow for unprecedented durability. This progress enables machinery to handle heavier workloads without compromising reliability.

The secret lies in perfecting every detail - from tooth profile to load distribution. When all elements align, the results speak for themselves in uninterrupted operation.

Advanced Manufacturing and Design Techniques

3D printing and other additive manufacturing methods revolutionize gear production. These technologies enable geometries that were previously impossible or prohibitively expensive. The resulting designs often outperform traditional approaches in both efficiency and durability.

Simulation software allows engineers to test countless iterations virtually. This digital prototyping accelerates development while reducing costly physical testing. The combination of advanced design tools and manufacturing methods pushes gear technology into exciting new territory.