The significance of dynamic balancing in modern tires

Beyond the Basics: How Dynamic Balancing Impacts Vehicle Handling

Beyond the Fundamentals of Dynamic Balancing

Dynamic balancing, often overlooked in introductory mechanics courses, is a crucial process for ensuring the smooth and efficient operation of rotating machinery. It involves adjusting the distribution of mass in a rotating component to eliminate imbalances that can lead to vibrations and premature wear. Understanding the principles behind dynamic balancing is essential for preventing costly repairs and maximizing the lifespan of critical equipment.

Properly executed dynamic balancing significantly reduces the detrimental effects of vibration, extending the service life of rotating parts. This proactive approach to maintenance saves considerable time and money by preventing equipment failures that may require extensive and expensive repairs.

Understanding the Impact of Imbalance

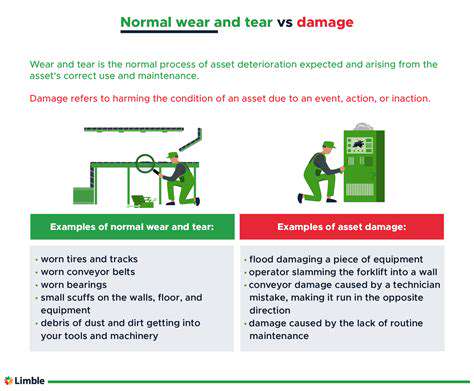

Rotating machinery, from turbines to fans, is inherently susceptible to imbalance. This imbalance, a deviation from perfect mass distribution, creates a centrifugal force that causes vibrations. These vibrations propagate through the machine, potentially causing damage to bearings, shafts, and other components. The severity of the damage correlates directly to the magnitude of the imbalance and the operating speed of the machinery.

Unbalanced forces can lead to significant noise pollution, reduced efficiency, and even catastrophic failures. Understanding the potential consequences of imbalance is critical for implementing effective preventative measures.

Techniques for Achieving Dynamic Balance

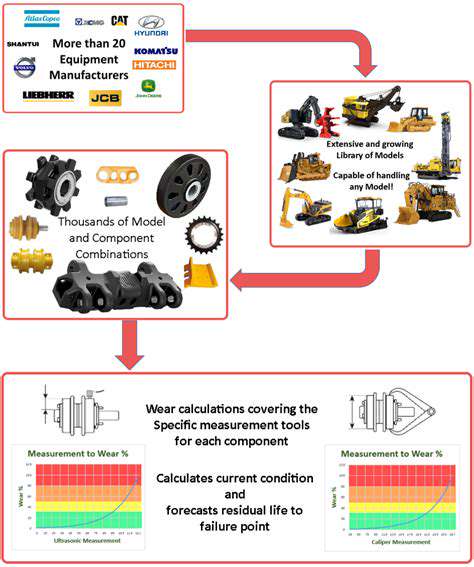

Several sophisticated techniques are employed to achieve dynamic balance. One common method involves using a dynamic balancing machine that measures the existing imbalance in a component. This machine then guides the operator in adding or removing material to counterbalance the imbalance, ensuring a precise and uniform mass distribution. Another, less common approach, relies on advanced computational modeling that predicts the ideal counterbalance required to eliminate vibrations before physical adjustments.

Advanced Applications in Various Industries

The principles of dynamic balancing are not confined to a single industry. From aerospace, where precision is paramount, to manufacturing, where efficiency is crucial, dynamic balancing plays a vital role. In the aerospace industry, for instance, precise dynamic balancing is essential for the smooth operation of aircraft engines and components.

Furthermore, in the automotive sector, dynamic balancing is used to ensure the optimal performance of vehicle wheels and drive shafts, contributing to enhanced ride quality and minimizing vibration.

The Future of Dynamic Balancing Technology

Advancements in sensor technology and computational modeling are pushing the boundaries of dynamic balancing. Real-time monitoring systems are becoming increasingly sophisticated, enabling predictive maintenance strategies that identify potential imbalances before they cause significant damage. This proactive approach minimizes downtime and optimizes machine performance.

Integration of AI and machine learning with dynamic balancing systems further enhances accuracy and efficiency by automating the balancing process and identifying subtle imbalances that might go unnoticed with traditional methods.

The automotive world is undergoing a radical transformation with the emergence of connected electric vehicles (EVs), evolving from mere transportation tools to intelligent, integrated systems. This revolutionary connectivity, commonly known as the Internet of Vehicles, enables EVs to exchange information with other vehicles, infrastructure, and even smartphones, forming a dynamic network that optimizes performance through shared data. This integration represents a fundamental change in how we perceive mobility, unlocking unprecedented opportunities for safety improvements, energy efficiency, and user convenience.