HTML Element

CSS Style

Maintenance

Fluid Levels

HTML

CSS

Power Steering

Power Steering Reservoir: Fluid Levels

- Fluid extraction bulb for precise level adjustment

- Digital pH tester to check fluid condition

- UV dye kit for leak detection

Preparing Your Vehicle for Inspection

Follow this detailed preparation sequence:

- Position the vehicle on completely level ground

- Engage the parking brake firmly

- Allow 30 minutes cooling time for hot engines

- Open hood and secure with prop rod

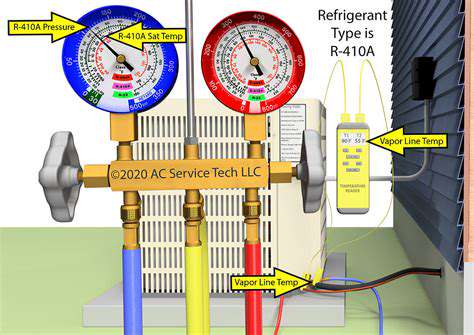

Checking the Fluid Level

For reservoirs with dipsticks:

- Remove and wipe clean with lint-free cloth

- Reinsert fully and remove again

- Check both sides of the dipstick

- Observe cold/hot level markings

- Note fluid color (should be reddish or amber)

- Check for bubbles or foam

Adding Power Steering Fluid (If Needed)

When topping up:

- Use a long-neck funnel to prevent spills

- Add small amounts (2-3oz at a time)

- Wait 30 seconds between additions

Additional Tips and Precautions

Seasoned mechanics recommend:

- Checking levels monthly or before long trips

- Changing fluid every 50,000 miles

- Inspecting hoses during oil changes

Correctly Adding Power Steering Fluid

Checking the Power Steering Fluid Level

Modern vehicles increasingly use electronic power steering, but hydraulic systems still dominate the market. When checking levels:

- Note whether the reading is for cold or hot fluid

- Check for proper viscosity (should coat the dipstick)

- Smell for burnt odors indicating overheating

Identifying the Correct Power Steering Fluid

Fluid types include:

- ATF (Automatic Transmission Fluid)

- CHF (Central Hydraulic Fluid)

- PSF (Power Steering Fluid)

- Check the cap for specifications

- Consult the maintenance manual

- Contact the dealership parts department

Preparing the Necessary Tools and Materials

Beyond basic tools, consider:

- Magnetic parts tray to keep fasteners organized

- LED work light for better visibility

- Turkey baster for fluid removal

Adding the Power Steering Fluid

Professional technique:

- Clean the cap area to prevent debris entry

- Turn cap slowly to relieve any pressure

- Pour fluid along the reservoir wall to minimize aeration

Checking the Fluid After Addition

Post-fill verification steps:

- Run engine for 2 minutes

- Check for proper level again

- Inspect for leaks at connections

Important Safety Precautions

Critical safety measures:

- Wear nitrile gloves to prevent skin contact

- Use safety glasses when working under the hood

- Keep rags away from moving belts

Troubleshooting Power Steering Fluid Issues

Power Steering Fluid Leaks

Leak detection requires systematic inspection:

- Check the pump shaft seal (common failure point)

- Inspect all hose connections

- Examine the rack and pinion boots

Power Steering Pump Issues

Pump failure symptoms progress through stages:

- Initial whining during cold starts

- Constant noise at all temperatures

- Complete loss of power assist

Steering Gear Problems

Rack and pinion issues manifest as:

- Fluid leaks at the bellows

- Play in the steering wheel

- Uneven tire wear patterns

Low Power Steering Fluid

Beyond checking levels, monitor:

- Steering effort changes

- Unusual noises when turning

- Fluid temperature after driving

Steering Wheel Play

Diagnosing play requires:

- Engine off tests for mechanical looseness

- Engine running tests for hydraulic issues

- Road testing for speed-sensitive symptoms

Electrical System Malfunctions

For electric power steering:

- Check fuse and relay first

- Scan for diagnostic trouble codes

- Test torque sensor operation

Read more about Power Steering Reservoir: Fluid Levels

Web Page Description for Enhanced Vehicle Drivetrain KnowledgeExplore the intricate components that make up your vehicle's drivetrain in our comprehensive guide. From understanding transmission types—manual, automatic, and continuously variable—to the pivotal roles played by the driveshaft, differential, axles, clutch, and gearbox, gain insights into how these systems work together to optimize performance and efficiency. Delve into the benefits of proper maintenance, common issues, and modern innovations that enhance your vehicle's driving dynamics. Whether you're a car enthusiast or a casual driver, understanding these elements is essential for making informed decisions about your vehicle and ensuring it runs smoothly. Learn more about ensuring longevity, fuel efficiency, and an enjoyable driving experience!

Jan 28, 2025

Discover the essential strategies for maintaining your vehicle's differential and optimizing overall performance. Our detailed article covers regular inspection techniques, the importance of fluid maintenance, the role of diagnostics, and tire wear analysis. Learn how to recognize early signs of differential issues, implement effective vibration and temperature monitoring, and engage in predictive maintenance to prevent costly failures. Equip yourself with knowledge and best practices for proactive vehicle care, ensuring safety and longevity on the road. Explore training programs designed for mechanics and enthusiasts alike to enhance awareness and skills in identifying differential failures. Transform your approach to automotive maintenance today!

Mar 09, 2025

Use a reliable tire pressure gauge to ensure your tires are inflated to the manufacturer's recommended psi, typically found on a sticker inside the driver’s door frame. - Monitor for Weather Changes: Temperature fluctuations can affect tire pressure—generally, each 10°F drop in temperature causes a 1 psi decrease. Be vigilant during seasonal changes. - Driving Habits Matter: Smooth, steady driving not only improves fuel economy but also affects rolling resistance. Aggressive driving can increase energy expenditure, leading to higher fuel consumption.- Invest in Technology: Consider a tire pressure monitoring system (TPMS) to alert you of low pressure conditions, enhancing convenience and safety.By integrating these practices into your vehicle maintenance routine, you can significantly enhance fuel efficiency, extend tire life, and contribute to a more sustainable driving experience. Don't overlook the simple yet impactful task of maintaining proper tire pressure—your wallet and the environment will thank you.

Mar 27, 2025

Regular flushes help in removing debris that can obstruct coolant flow, ensuring that your engine stays cool and reducing the chance of severe damage. 2. Improved Cooling Efficiency: Fresh coolant is essential for optimal heat transfer. A clean radiator can enhance heat dissipation by up to 15%, ensuring your engine runs efficiently.3. Enhanced Engine Performance: A clean cooling system results in improved fuel economy and a more reliable engine, as it allows for optimal combustion conditions.4. Corrosion Prevention: Routine flushing removes corrosive substances, significantly minimizing the risk of long-term damage to the radiator and other components.5. Cost-Effectiveness: Investing in regular flushes is much cheaper than the expenses associated with major repairs due to neglect. Signs Your Vehicle Needs a Radiator FlushBe vigilant for the following indicators that signal it’s time for a radiator flush:- Overheating Engine: Frequent overheating suggests an ineffective cooling system.- Low Coolant Levels: Regularly checking your coolant can help determine the need for a flush.- Discolored Coolant: Rusty or murky coolant is a clear sign of contamination. Recommended Frequency for Radiator FlushesMost experts recommend flushing the radiator every 30,000 to 50,000 miles or every two years. However, individual factors, such as driving habits and environmental conditions, may necessitate more frequent maintenance. How to Perform a Radiator FlushFor those interested in DIY maintenance, a radiator flush can be performed with basic tools and coolant. Here's a brief overview of the process:1. Let your vehicle cool down completely.2. Drain the old coolant into a safe container.3. Add a radiator flush solution, run the engine, and then drain it again.4. Rinse with water and refill with a fresh coolant mixture. The Bottom LineNeglecting the radiator can lead to costly repairs and decreased vehicle longevity. Emphasizing regular radiator flushes ensures that your vehicle operates smoothly and efficiently, enhancing both performance and reliability. Protecting your investment starts with proper maintenance; don’t overlook the benefits of a well-maintained cooling system.

Apr 04, 2025

Essential Regular Checks and ServicingMaintaining your vehicle's Anti-lock Braking System (ABS) is crucial for safety and performance. Understanding how ABS works and staying on top of its maintenance can prevent accidents and costly repairs. This article delves into the key aspects of ABS maintenance, guiding you through essential checks and servicing tips to keep your braking system in optimal condition. What is ABS?The Anti-lock Braking System (ABS) is designed to prevent wheel lock-up during braking. By modulating brake pressure, ABS allows drivers to maintain steering control during hard braking, particularly in slippery conditions. A well-functioning ABS not only enhances safety but also improves overall driving control. Importance of Regular ABS ChecksTo ensure the reliability of your ABS, regular inspections are necessary. While the system is designed to self-check, external factors such as harsh weather conditions, wear and tear on components, and fluid levels can affect its functionality. Here are some routine checks you should consider: 1. Brake Fluid Level and QualityBrake fluid plays a vital role in the functioning of the ABS. Regularly check the fluid level and its condition. If the fluid appears dark or contaminated, it's a sign that it needs to be replaced. Remember, keeping the brake fluid clean helps maintain the hydraulic properties essential for effective braking. 2. ABS Warning LightPay attention to the ABS warning light on your dashboard. If this light illuminates, it indicates a malfunction within the ABS system. Ignoring this warning can lead to compromised braking performance. Diagnostics should be undertaken promptly to identify and rectify the issue. 3. Sensor FunctionalityABS relies on wheel speed sensors to detect wheel rotation and prevent locking. Make it a routine to inspect these sensors for any dirt or damage. A malfunctioning sensor can lead to undesired ABS behavior and must be addressed immediately. 4. Brake Pads and RotorsEnsure that your brake pads and rotors are in good condition. Worn-out pads can affect the overall performance of the ABS. Regular inspection and timely replacement are key to maintaining effective braking performance. 5. Professional ServicingWhile many ABS checks can be performed by vehicle owners, it’s advisable to seek professional help for thorough diagnostics, especially if you notice any irregularities during your inspections. Professional mechanics have specialized tools to diagnose and service ABS issues accurately. ConclusionIn summary, maintaining your Anti-lock Braking System through regular checks and timely servicing is essential for your safety on the road. By understanding its components and functions, you can ensure that your ABS operates efficiently and effectively. Prioritize your vehicle’s braking system maintenance and consider professional assistance for any concerns. Drive safe, and enjoy peace of mind knowing your braking system is in top shape.For more information on ABS maintenance and automotive safety, stay tuned to our blog!

Apr 30, 2025

Choosing the ideal car polish for protecting vehicle finishes

Apr 30, 2025

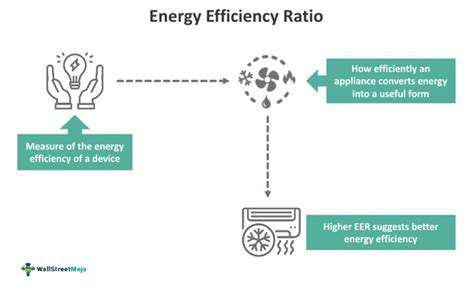

Diagnosing and repairing common car AC compressor issues

May 03, 2025

How proper gearing improves torque in heavy duty vehicles

May 10, 2025

A technical approach to preventing valve cover gasket leaks

May 11, 2025

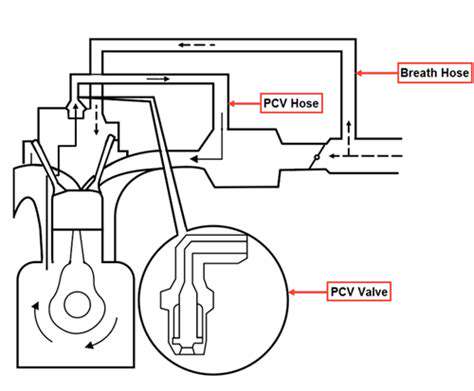

Understanding the role of PCV valves in modern engines

May 14, 2025

The importance of regular calibration for vehicle sensors

May 15, 2025

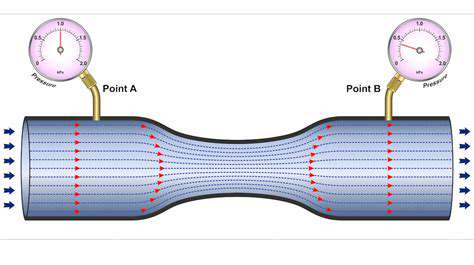

The importance of fluid dynamics in maintaining hydraulic systems

May 22, 2025