Spoilers & Wings: Downforce & Styling

The Crucial Role of Spoilers and Wings in Automotive Design

The Nature of Spoilers

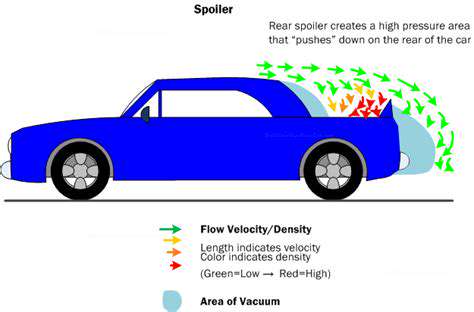

Spoilers, at their core, are aerodynamic components designed to manipulate airflow, improving vehicle stability and performance. These elements range from subtle lip spoilers to aggressive rear wings, each serving distinct purposes in automotive engineering. Understanding their functional differences is key to appreciating their impact on vehicle dynamics.

Spoilers are intentionally integrated into vehicle designs for specific performance benefits, such as reducing lift or increasing downforce. However, improperly designed spoilers can create unintended drag, negatively affecting fuel efficiency and top speed.

The Impact on Vehicle Performance

The effect of spoilers on vehicle performance is multifaceted and depends on their design and application. For racing applications, properly tuned spoilers can dramatically improve cornering grip, allowing drivers to maintain higher speeds through turns. This enhancement directly translates to better lap times and more predictable handling characteristics.

Conversely, poorly designed spoilers can degrade performance, creating excessive drag without sufficient downforce benefits. This negative impact is particularly noticeable at highway speeds where aerodynamic efficiency becomes crucial.

The Engineering Considerations of Spoiler Design

The technical aspects surrounding spoiler development involve complex fluid dynamics and require careful balancing between multiple performance factors. Engineers must consider the vehicle's intended use, typical operating speeds, and overall aerodynamic profile when designing these components.

Optimal spoiler placement and angle can significantly impact a vehicle's aerodynamic efficiency. This is especially critical in motorsports where marginal gains can determine race outcomes.

The Role of Spoilers in Modern Automotive Design

In today's competitive automotive market, spoilers have become integral elements of both performance and aesthetic design. From subtle integrated lips on sedans to massive adjustable wings on supercars, these components serve functional and visual purposes.

This integration of form and function raises important questions about design priorities and how manufacturers balance aesthetic appeal with genuine performance benefits.

Spoiler Testing and Validation Methods

Wind tunnel testing, while resource-intensive, remains the gold standard for spoiler development. These tests provide precise data on downforce generation, drag coefficients, and airflow patterns, allowing engineers to refine designs before production.

Implementing computational fluid dynamics (CFD) simulations early in the design process can reduce development time and costs while still providing valuable aerodynamic insights. Ultimately, creating effective spoilers requires both theoretical knowledge and practical validation.

The Evolution of Spoiler Technology

Advancements in materials science and manufacturing have revolutionized spoiler design. The shift from fixed metal components to lightweight composites and active aerodynamic systems has dramatically improved performance while reducing weight.

This technological progression necessitates more sophisticated design approaches as engineers push the boundaries of what's possible with aerodynamic components. Understanding this evolution is crucial for appreciating modern automotive engineering achievements.

Styling Considerations and Integration

Choosing the Right Aerodynamic Profile

Aerodynamic profile selection is crucial for creating effective spoiler designs. Consider the vehicle's intended purpose and typical operating conditions when determining the optimal shape. A daily driver might benefit from a subtle, low-drag design, while a track-focused vehicle requires aggressive downforce-generating elements.

Experiment with different profiles through simulation and physical testing to identify the most effective configuration. Consistent aerodynamic philosophy throughout the vehicle's design enhances overall performance and creates visual harmony. Always balance aesthetic goals with functional requirements when making design decisions.

Material Selection and Weight Considerations

The choice of materials significantly impacts both performance and durability. Lightweight composites like carbon fiber offer excellent strength-to-weight ratios but come at higher costs. Traditional materials like aluminum or ABS plastic may be more cost-effective for production vehicles.

Prioritize materials that meet performance requirements without unnecessarily increasing weight or complexity. Consider the manufacturing processes available and how they might influence final part quality and consistency.

Integration With Vehicle Bodywork

Successful spoiler designs seamlessly integrate with the vehicle's existing lines and contours. Poor integration can create turbulent airflow and negate potential benefits. High-quality integration contributes to both aerodynamic efficiency and visual appeal.

Consider how the spoiler interacts with other aerodynamic elements like diffusers and side skirts. The entire aerodynamic package should work cohesively to manage airflow around the vehicle.

Active vs Passive Aerodynamic Systems

Modern vehicles increasingly incorporate active aerodynamic elements that adjust based on speed and driving conditions. These systems offer performance advantages but add complexity and potential failure points.

Proper implementation of active systems can provide the benefits of multiple fixed designs in a single package. Evaluate whether the performance gains justify the additional cost and maintenance requirements for the intended application.

Manufacturing and Production Considerations

Design decisions must account for production realities. Complex shapes may require specialized tooling or manufacturing processes that impact cost and lead time. Early collaboration between design and manufacturing teams helps identify potential issues before they become costly problems.

Consider how design choices affect assembly processes and serviceability. Components that are difficult to install or repair may lead to higher warranty costs or customer dissatisfaction.

The Evolution of Spoiler and Wing Technology

Early Automotive Aerodynamic Experiments

Pioneering automotive engineers in the early 20th century began experimenting with basic aerodynamic modifications. These early efforts, while crude by modern standards, demonstrated the potential benefits of managing airflow around vehicles. The understanding of automotive aerodynamics was still developing, with many concepts borrowed from aviation.

The Rise of Scientific Aerodynamics

The application of rigorous aerodynamic principles transformed automotive design in the mid-20th century. As engineers gained better understanding of airflow patterns and pressure distribution, they developed more effective spoiler designs. This period saw the transition from purely aesthetic additions to properly functional aerodynamic components.

The Introduction of Purpose-Built Racing Spoilers

Motorsports became the proving ground for advanced spoiler technology. Race teams developed increasingly sophisticated designs to gain competitive advantages. The lessons learned on the track gradually filtered down to production vehicles, improving stability and safety for everyday drivers.

The Downforce Revolution

The realization that spoilers could generate meaningful downforce revolutionized high-performance vehicle design. Engineers developed wings and spoilers that could significantly increase tire grip without proportionally increasing drag. This breakthrough allowed higher cornering speeds while maintaining straight-line performance.

Modern Computational Design Methods

Contemporary spoiler design heavily relies on advanced computational fluid dynamics simulations. These tools allow engineers to test countless iterations virtually before committing to physical prototypes. The precision offered by modern software has led to more efficient designs that extract maximum performance from minimal components.

Material Advancements in Spoiler Construction

The materials used in spoiler manufacturing have evolved dramatically. From early steel and aluminum constructions to modern carbon fiber and advanced composites, these developments have enabled lighter, stronger, and more durable components. Material science continues to push the boundaries of what's possible in aerodynamic design.

The Future of Automotive Aerodynamics

Spoiler technology continues to evolve alongside vehicle design trends. Emerging technologies like active aero systems and airflow manipulation devices promise even greater performance benefits. The relationship between spoiler design and overall vehicle aerodynamics remains a critical area of innovation in the automotive industry.