Understanding the role of EGR valves in emission control systems

The Thermodynamics of EGR Operation

The effectiveness of EGR stems from fundamental thermodynamic principles. When exhaust gases mix with the fresh air-fuel charge, they increase the mixture's specific heat capacity - meaning more energy is required to raise its temperature. This thermodynamic effect creates a double benefit: lower peak temperatures reduce NOx formation while also minimizing energy lost through the exhaust system. Engineers carefully calibrate EGR rates to balance emissions reduction with maintaining sufficient combustion efficiency for proper engine operation.

EGR Valve Engineering and Operation

Modern EGR valves represent marvels of precision engineering. These components must operate reliably in extremely harsh environments, withstanding temperatures exceeding 1,200°F (650°C) while maintaining precise flow control. The latest designs incorporate advanced materials like silicon carbide ceramics and high-nickel alloys to resist thermal degradation and corrosive exhaust gases. Many systems now use electronic actuators with position feedback sensors, allowing the engine control unit to adjust EGR flow rates in real-time based on operating conditions.

Future Directions in EGR Technology

Engineers continue refining EGR systems to address current limitations while improving performance. New designs focus on reducing carbon buildup through improved flow paths and self-cleaning mechanisms. Some prototypes incorporate plasma-assisted combustion to maintain stable ignition with higher EGR rates. Researchers are also developing predictive control algorithms that anticipate driving conditions to optimize EGR operation proactively. These innovations aim to meet increasingly stringent emissions standards while maintaining or improving engine efficiency.

Types of EGR Systems and Their Applications

EGR System Variants

Automakers have developed several EGR system configurations to meet different performance and emissions requirements. The choice between systems depends on factors including engine size, intended application, and cost considerations. Each design represents a unique approach to solving the fundamental challenge of NOx reduction while maintaining drivability.

Conventional Valve-Based Systems

The most common EGR configuration uses a vacuum or electronically-controlled valve to meter exhaust gas flow. These systems offer good reliability and relatively simple maintenance. Proper valve maintenance is crucial - sticking valves represent one of the most common EGR system failures. Many modern designs incorporate position sensors that allow the engine computer to detect and compensate for valve wear over time.

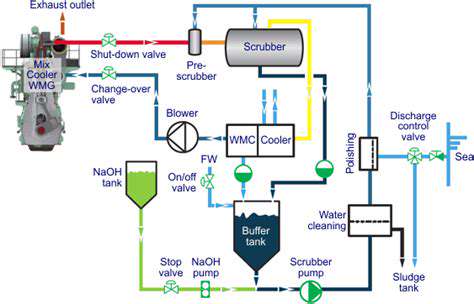

Cooled EGR Systems

High-performance and diesel applications often use heat exchangers to cool recirculated exhaust gases before they re-enter the intake. This cooling dramatically increases the mass of exhaust gas that can be recirculated without sacrificing performance. The cooler's design must prevent condensation while maximizing heat transfer - a challenging balance that requires careful engineering. Many systems use engine coolant as the heat transfer medium, though some high-efficiency designs employ separate cooling circuits.

Advanced Control Systems

State-of-the-art EGR systems integrate multiple sensors and sophisticated control algorithms. These systems continuously monitor factors like exhaust temperature, oxygen content, and engine load to optimize EGR flow. Some designs can vary EGR rates cylinder-by-cylinder for maximum efficiency. The control software often includes self-diagnostic routines that can detect developing problems before they affect emissions or performance.

Variable Geometry Systems

Some manufacturers have developed EGR systems with adjustable flow paths that change based on operating conditions. These designs can provide optimal EGR rates across the entire engine speed range. The most advanced versions use electro-hydraulic actuators that can adjust flow characteristics in milliseconds. While more complex than fixed-geometry systems, they offer superior performance particularly in turbocharged applications.

Integrated Emissions Solutions

Modern vehicles rarely rely on EGR alone for emissions control. The most effective systems combine EGR with other technologies like selective catalytic reduction (SCR) and particulate filters. This integrated approach allows each component to operate in its most effective range, maximizing overall system efficiency. The engine control unit coordinates all these systems, creating a comprehensive emissions management strategy.

Architectural integration principles apply equally well to engine systems, where coordinated component design enhances overall performance.