Diagnosing and addressing unusual noises in car HVAC systems

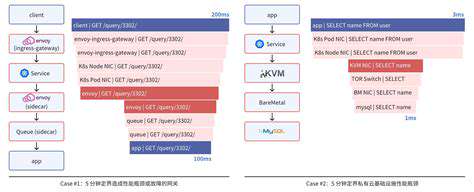

Environmental elements like unstable network connections or external interference can dramatically affect system operations. Determining whether outside factors contribute to the problem enables the creation of more targeted solutions. Implementing regular maintenance checks and continuous monitoring helps prevent minor issues from becoming major headaches, ultimately conserving both time and resources.

Implementing Diagnostic Techniques for Accurate Identification

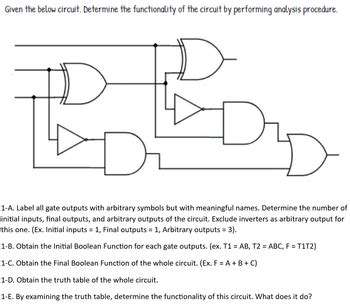

Successful troubleshooting begins with gathering detailed information about when and how the problem manifests. Technicians rely heavily on specialized tools including log analysis software, diagnostic programs, and performance monitoring utilities. These instruments provide concrete data that reveals patterns or abnormalities connected to the malfunction.

Methodical troubleshooting approaches - such as component isolation, controlled environment testing, and issue replication - prove essential for narrowing down possible causes. Precisely identifying the problem's origin represents the crucial first step toward developing an effective fix and preventing future recurrences.

Pinpointing Potential HVAC System Issues

Understanding HVAC System Components

HVAC systems combine heating, ventilation, and air conditioning into complex networks designed to maintain indoor comfort. Recognizing how individual components function - from furnaces and heat pumps to ductwork and air handlers - proves vital for identifying potential problems. Consistent maintenance and routine inspections frequently prevent expensive repairs while ensuring peak system performance. This requires recognizing malfunction indicators in each component and understanding how system elements interconnect.

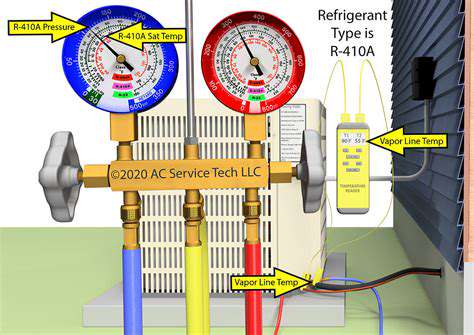

The compressor, a critical cooling cycle component, handles refrigerant compression. Faulty compressors rank among the most common HVAC failure points, often resulting in skyrocketing energy costs or complete system failures. Similarly, understanding refrigerant circulation proves essential since leaks or blockages reduce efficiency and may create hazardous situations. Proper refrigerant management impacts both system efficiency and safety.

Troubleshooting Common HVAC Issues

Typical HVAC problems often appear as strange noises, temperature fluctuations, or reduced airflow. Recognizing these warning signs represents the initial troubleshooting step. For instance, loud compressor clicking might indicate motor or compressor issues. Pinpointing specific symptoms proves crucial for determining appropriate corrective actions and potential part replacements.

Regular maintenance and preventive checks substantially decrease the likelihood of major system failures. Qualified technician inspections can catch problems early, avoiding costly future repairs. These inspections include leak detection, airflow verification, and component operation checks. Neglecting these maintenance recommendations might trigger cascading system failures requiring extensive, expensive repairs or complete replacements.

Preventive Maintenance Strategies

Establishing proactive HVAC maintenance schedules maximizes system lifespan and efficiency. This includes routine filter changes, airflow optimization, and wear-and-tear inspections. Consistent upkeep prevents expensive future repairs while ensuring year-round optimal HVAC performance.

Annual professional inspections surpass typical homeowner capabilities by identifying issues like refrigerant leaks or electrical problems. Certified HVAC technicians possess specialized knowledge and equipment to accurately diagnose issues and recommend optimal solutions. This proactive approach helps avoid major breakdowns while maintaining peak system efficiency for extended periods.

Diagnosing Clicking and Grinding Sounds

Identifying the Source of the Clicking Noise

Clicking noises in vehicles can originate from various mechanical issues, making accurate source identification essential for proper repairs. The noise's location (front, rear, engine bay), consistency (intermittent/constant), and triggering circumstances (acceleration, braking, idling) provide critical diagnostic clues. Front-end clicking during turns might suggest worn ball joints or tie rods. Understanding these contextual details significantly narrows diagnostic possibilities.

Clicking noises sometimes accompany other symptoms like steering responsiveness loss or steering wheel vibrations. Noticing these additional indicators helps identify problematic components. For example, acceleration-related clicking might indicate transmission issues, while intermittent clicking could point to loose parts or temporary malfunctions.

Analyzing the Nature of the Grinding Sound

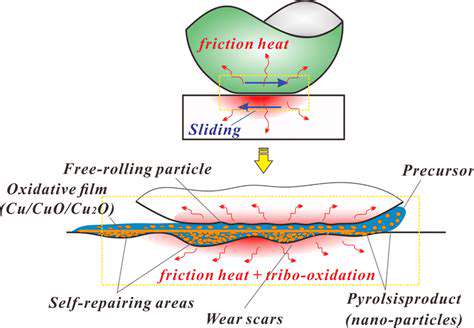

Unlike clicking, grinding noises typically indicate serious mechanical problems involving metal-on-metal contact from damaged components. These sounds demand immediate attention to prevent further damage. Identifying when grinding occurs (accelerating, braking, turning) helps diagnose potential causes like worn bearings, damaged gears, or failing parts.

Examining the Timing of the Noise

Noise timing during vehicle operation provides critical diagnostic information. Acceleration-only grinding might indicate transmission problems, while steering-related clicking could suggest power steering pump or steering rack issues. Noise consistency (constant/intermittent) also provides valuable diagnostic clues.

Considering the Location of the Noise

Pinpointing noise location (front end, engine compartment, rear, interior) helps identify potential problem areas. Front-end noises might indicate suspension, steering, or brake issues, while engine bay noises could suggest valve train or bearing problems.

Checking for Associated Symptoms

Unusual noises often accompany other symptoms like vibrations, power loss, unusual odors, or fluid leaks. For example, grinding with power loss might indicate transmission or engine problems, while clicking with fluid leaks could suggest hydraulic system issues.

Seeking Professional Diagnosis and Repair

While basic troubleshooting helps narrow possibilities, complex mechanical issues like clicking/grinding noises require professional attention. Qualified mechanics possess necessary expertise and tools for accurate diagnosis and proper repairs. Ignoring these noises often leads to more severe problems and costly fixes.

Accurate adolescent depression identification requires attention to characteristic signs indicating deeper psychological concerns. Beyond persistent sadness, irritability, or social withdrawal lasting over two weeks, some teens suddenly abandon favorite activities like music or sports. These behavioral shifts resemble fading artwork, requiring careful parental observation.

Addressing Hissing and Whistling Noises

Identifying the Source of the Noise

Locating hissing/whistling sources proves essential for effective troubleshooting. Thoroughly inspect the affected area for visible damage or unusual wear patterns, including loose connections, damaged parts, or airflow obstructions. A systematic approach - starting from most likely sources and expanding outward - enhances diagnostic accuracy.

Consider noise context: Does it occur only under load? Is it constant or intermittent? These details provide valuable diagnostic information about potential causes.

Potential Causes Related to Airflow

Hissing/whistling often stems from airflow problems. Restricted intake/exhaust systems can produce these sounds from debris, dust, or animal nest obstructions. Regular ventilation system cleaning prevents such issues.

Faulty fans or impellers represent another airflow-related cause. Damaged, bent, or improperly spinning fan blades can generate high-pitched whistling, as can loose/worn drive belts.

Evaluating Electrical Components

Sometimes hissing/whistling originates from electrical components like malfunctioning relays or capacitors, particularly in cooling/ventilation systems. These voltage/current regulation components can produce unusual sounds when faulty.

Inspecting Connections and Fittings

Loose/damaged connections and fittings frequently cause hissing/whistling. Carefully examine all system connections including pipes, ducts, and wiring. Pipe leaks or loose ventilation connections often produce hissing that tightening or repairing can resolve.

Considering Mechanical Wear and Tear

Mechanical component wear over time can create unusual sounds. Worn bearings, damaged impellers, or loose moving parts may produce whistling/hissing. Regular maintenance and lubrication prevents these issues and extends system lifespan. Identifying specific problematic components enables effective repairs.

Seeking Professional Assistance

If noise sources remain unidentified or issues cause significant system/safety concerns, consult qualified technicians. Professionals accurately diagnose problems and implement proper repairs. DIY attempts on complex/dangerous issues may cause further damage or injury.